Assembled tower base with steel and plastic structure and special hydraulic propeller

A combined tower crane and steel structure technology, applied in infrastructure engineering, construction, etc., can solve the problems of many manufacturing processes, high manufacturing costs, and damage to other facilities, and achieve the effects of wide application range, simple manufacturing, and simple disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

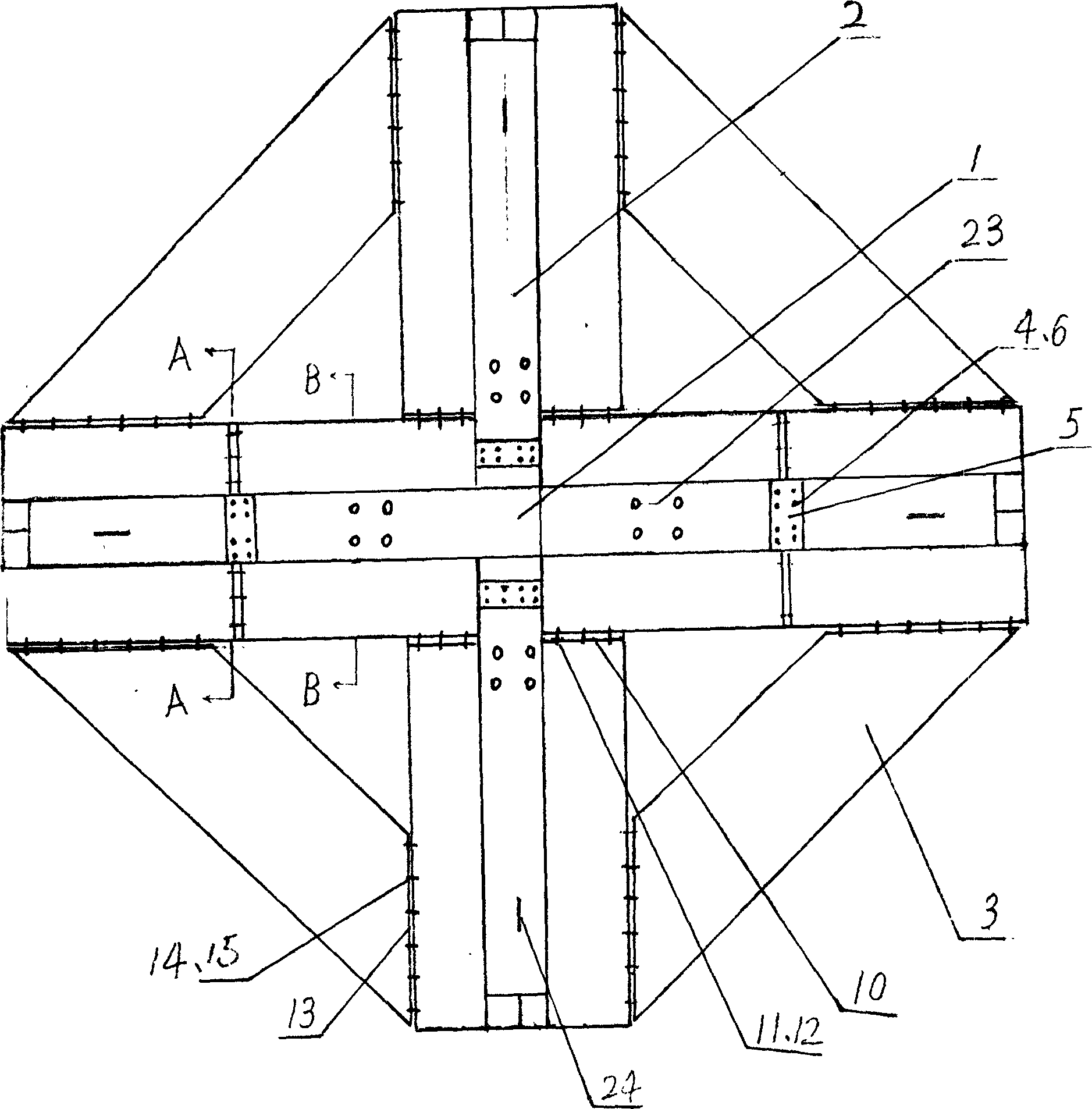

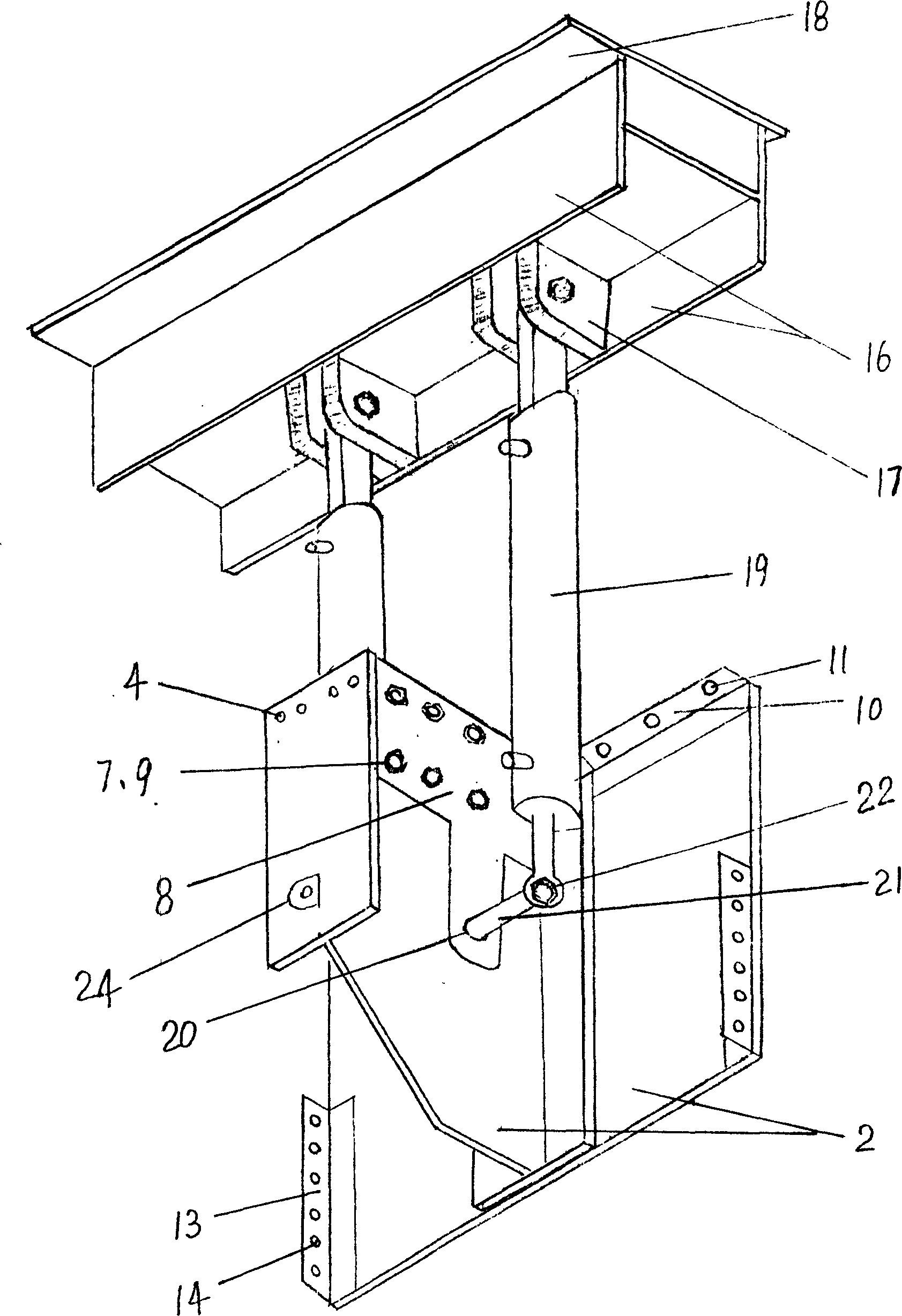

[0021] Such as figure 1 As shown, the combination of the present invention is composed of a central piece 1, an end piece 2, and a torsion-resistant counterweight 3. The cross-sections of the central piece 1 and the end-piece 2 are I-shaped, and the cross-section of the torsion-resistant counterweight is rectangular. In this embodiment, the material of the assembly is selected as a steel structure.

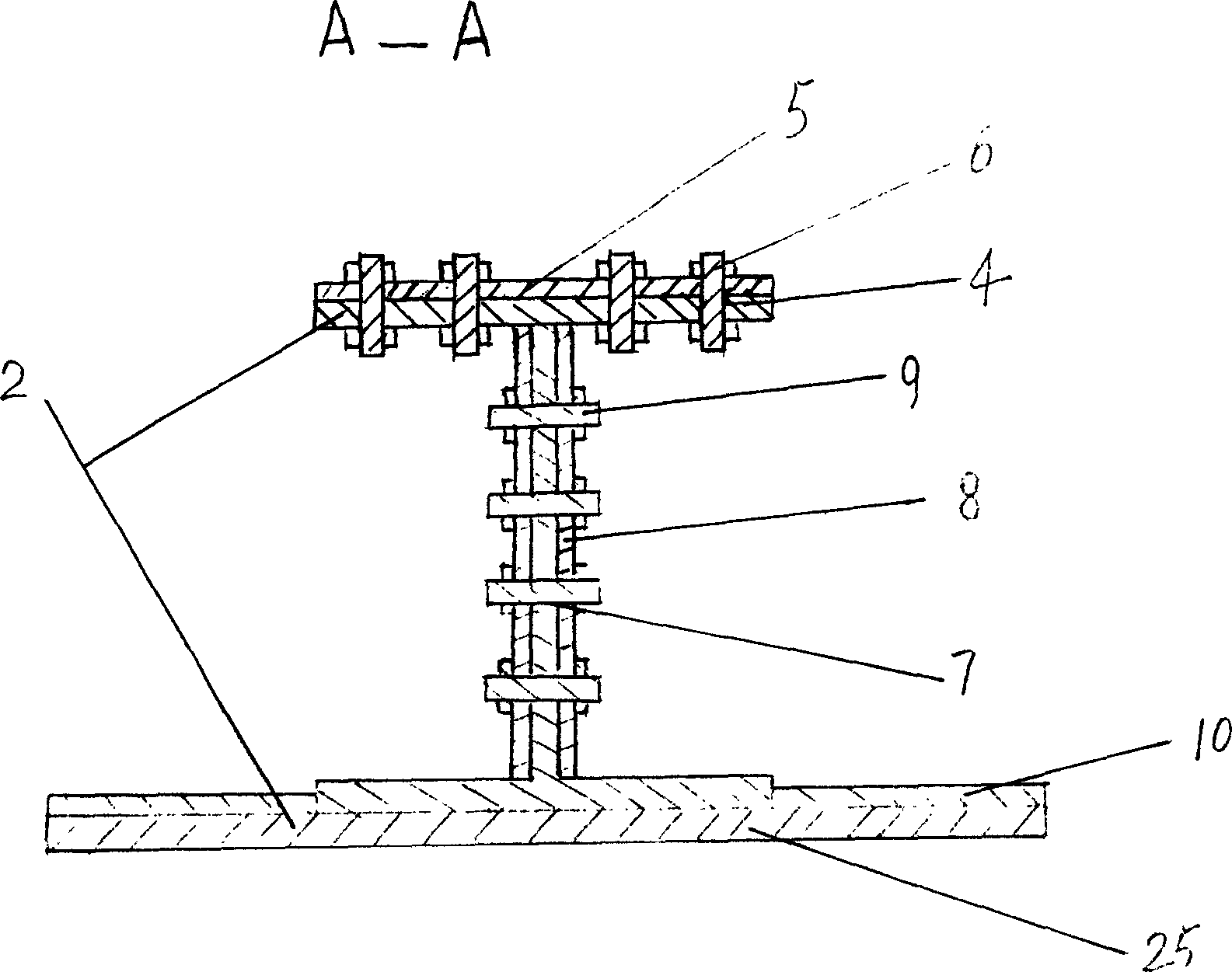

[0022] Such as figure 1 , figure 2 As shown, take I-shaped steel to make center piece 1 and end piece 2; as image 3 , Figure 4 As shown, the bottom of the I-shaped steel is welded with a torsion-resistant counterweight base plate 25, which is 10 times wider than the width of the upper wing plate of the I-shaped steel, so as to improve the anti-tipping ability of the foundation; figure 2 As shown, the opposite end of the end piece 2 and the joint end of the central piece 1 is sloped, and the included angle of the slope is 30 degrees, so as to reduce the resistance to propul...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap