Assembling method for Fullerene derivative in silicone meso porous material

A technology of fullerene derivatives and mesoporous materials, which is applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, and can solve problems such as damage to optical clipping intensity and triplet weakening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

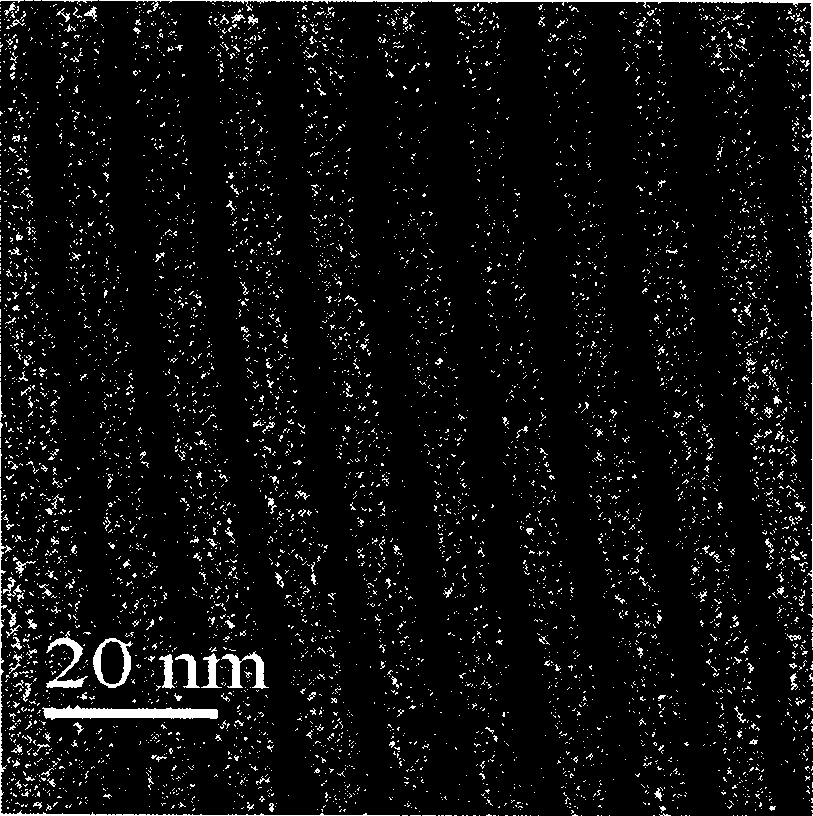

[0023] [60] Assembly of fullerene derivatives in mesoporous material SBA-15: at 10°C, press C 60 (CHCOOH) 2 2% by weight with APTS / SBA-15, add APTS / SBA-15 to C 60 (CHCOOH) 2 In THF, within 120 minutes, amidation reaction occurred, APTS / SBA-15 turned from white to brown, and C 60 (CHCOOH) 2 / APTS / SBA-15, filtered and washed with THF C 60 (CHCOOH) 2 / APTS / SBA-15, and finally remove the remaining solvent under vacuum. Put the material for 1 day and half a year to test the performance of the material respectively.

Embodiment 2

[0025] [60] Assembly of fullerene derivatives in mesoporous material SBA-15: at 45°C, press C 60 (CHCOOH) 2 / APTS / SBA-15 weight ratio is 4%, add APTS / SBA-15 to C 60 (CHCOOH) 2 In THF, within 60 minutes, amidation reaction occurred, APTS / SBA-15 turned from white to brown, and C 60 (CHCOOH) 2 / APTS / SBA-15, filtered and washed with THF C 60 (CHCOOH) 2 / APTS / SBA-15, and finally remove the remaining solvent under vacuum. Put the material for 1 day and half a year to test the performance of the material respectively.

Embodiment 3

[0027][60] Assembly of fullerene derivatives in mesoporous material SBA-15: at 90°C, press C 60 (CHCOOH) 2 4% by weight with APTS / SBA-15, add APTS / SBA-15 to C 60 (CHCOOH) 2 In THF, within 30 minutes, amidation reaction occurred, APTS / SBA-15 turned from white to brown, and C 60 (CHCOOH) 2 / APTS / SBA-15, filtered and washed with THF C 60 (CHCOOH) 2 / APTS / SBA-15, and finally remove the remaining solvent under vacuum. Put the material for 1 day and half a year to test the performance of the material respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com