Cast iron billet excelling in workability and process for producing the same

A technology with excellent workability and manufacturing method, applied in the field of cast iron, cast iron sheet and its manufacturing, can solve the problems of large solid-liquid coexistence area of white cast iron, incomplete spheroidization of graphite, and deterioration of workability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

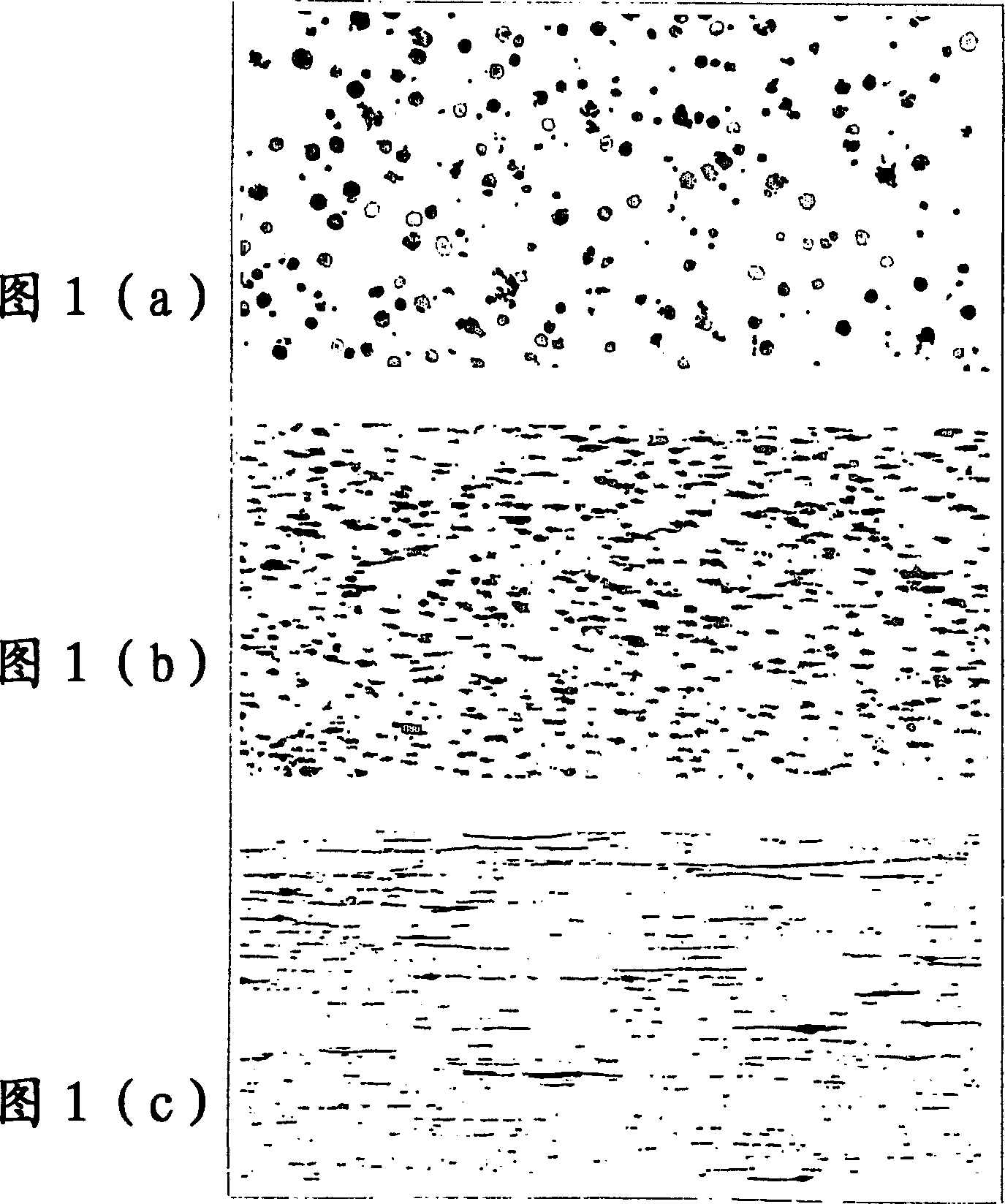

[0117] Cast iron having the chemical composition shown in Table 1 was melted in a melting furnace, a spheroidizer was added, and a 100 mm square metal block was cast. This white cast iron was hot-rolled to form a 3.5 mm thick hot-rolled sheet. Furthermore, cold rolling was performed on some of the hot-rolled sheets to obtain a 1.2 mm-thick cold-rolled sheet. Part of the hot-rolled sheet and the cold-rolled sheet obtained by rolling the white cast iron are heat-treated in a heating furnace. After heating, cool to room temperature through the specified temperature process.

[0118] On the other hand, an example using a conventional technique was performed as a comparative example. Specifically, in Comparative Example 1, ordinary spherical graphite cast iron molten iron was cast, and the obtained cast slab was hot-rolled. Also, in Comparative Example 2, casting was performed without adding a nodularizing agent to a molten cast iron of white cast iron composition, hot rolling a...

Embodiment 2

[0136] Add Ni-Mg nodularizer to C: 3.4% by mass, Si: 0.3% by mass cast iron iron water, Mg: 0.03% by mass, pass through a tundish, and use a vertical continuous casting machine using a water-cooled copper mold Continuously cast a slab with a thickness of 200mm and a width of 1000mm to produce cast slabs. exist Figure 4 The outline of the continuous casting machine is shown in .

[0137] A part of the slab was hot-rolled at 850° C. to form a 3 mm-thick hot-rolled sheet. Furthermore, a part of the hot-rolled sheet was cold-rolled to form a 1 mm-thick cold-rolled sheet. The hot-rolled sheet and the cold-rolled sheet thus obtained were heated at 1000° C. for 30 minutes in a heating furnace. Allow to cool to room temperature after heating. Samples were selected from the obtained cast sheets, hot-rolled sheets, cold-rolled sheets, and heat-treated sheets to investigate the morphology and distribution of graphite.

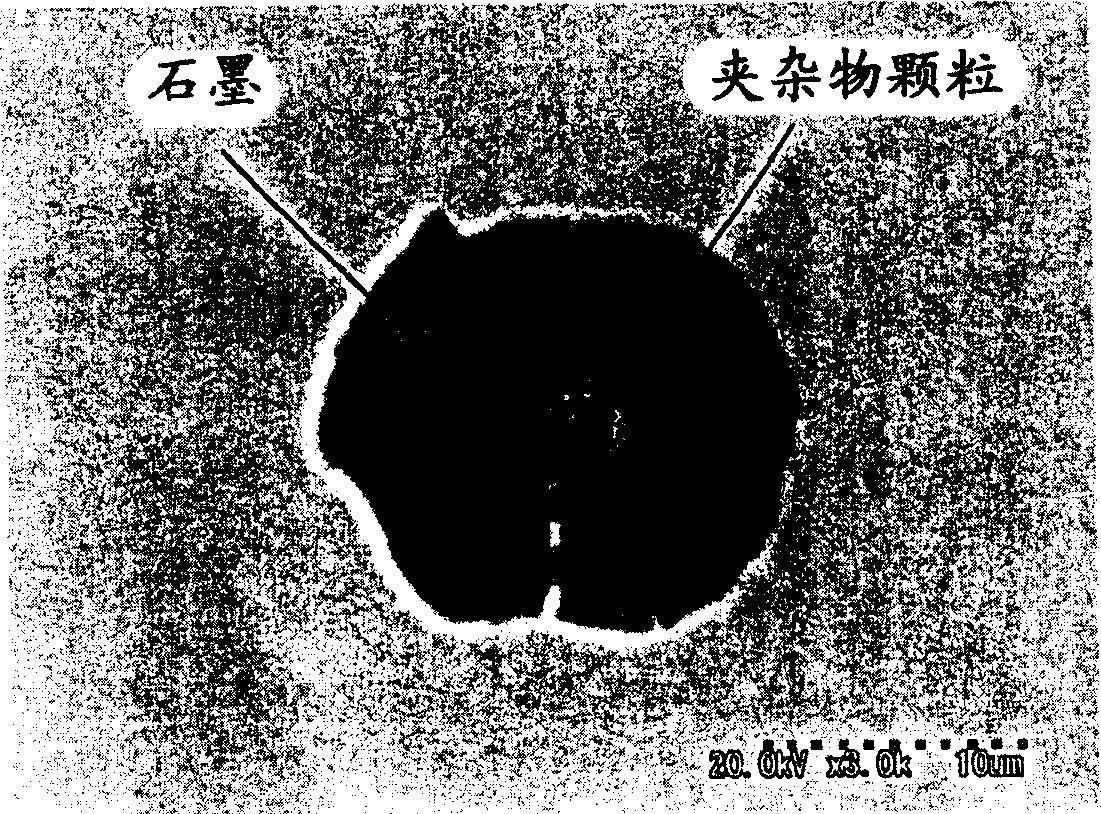

[0138] As a result, oxides and sulfides of Mg and particles of ...

Embodiment 3

[0142] Add a Ca-Si-based nodularizer to C: 2.4% by mass, Si: 0.7% by mass of cast iron iron water, take it as Ca: 0.005% by mass, Si: 1.0% by mass, and pass it through a tundish to use a water-cooled copper mold The thin slab continuous casting machine is used to cast thin slabs with a thickness of 50mm and a width of 900mm.

[0143]A part of the slab was hot-rolled at 800° C. into a 3.5 mm-thick hot-rolled sheet, and coiled into a coil. Furthermore, a part of the hot-rolled sheet was cold-rolled to form a 1.5 mm-thick cold-rolled sheet. The hot-rolled sheet and the cold-rolled sheet thus obtained were heated at 1000° C. for 30 minutes in a heating furnace. After heating, cool from 700°C to 300°C at a cooling rate of 1°C / min, and then leave to cool to room temperature. Samples were selected from the obtained cast sheets, hot-rolled sheets, cold-rolled sheets, and heat-treated sheets to investigate the morphology and distribution of graphite.

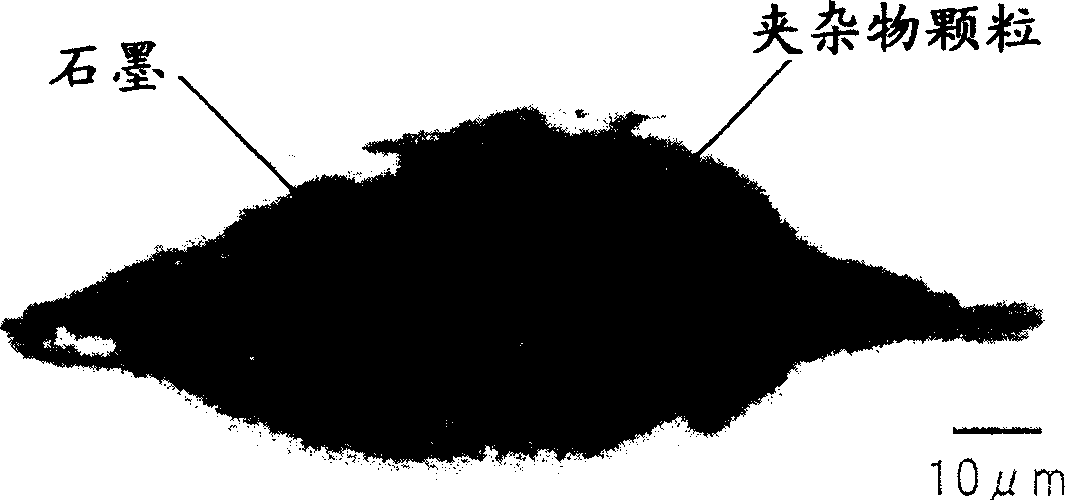

[0144] As a result, oxides and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com