Anti-forge coating white cardboard and producing method thereof

A production method and technology for white cardboard, applied in coating, paper, papermaking, etc., can solve the problems of complicated equipment, increased equipment, and large investment, and achieve the effect of uniform pattern distribution and increased imitation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

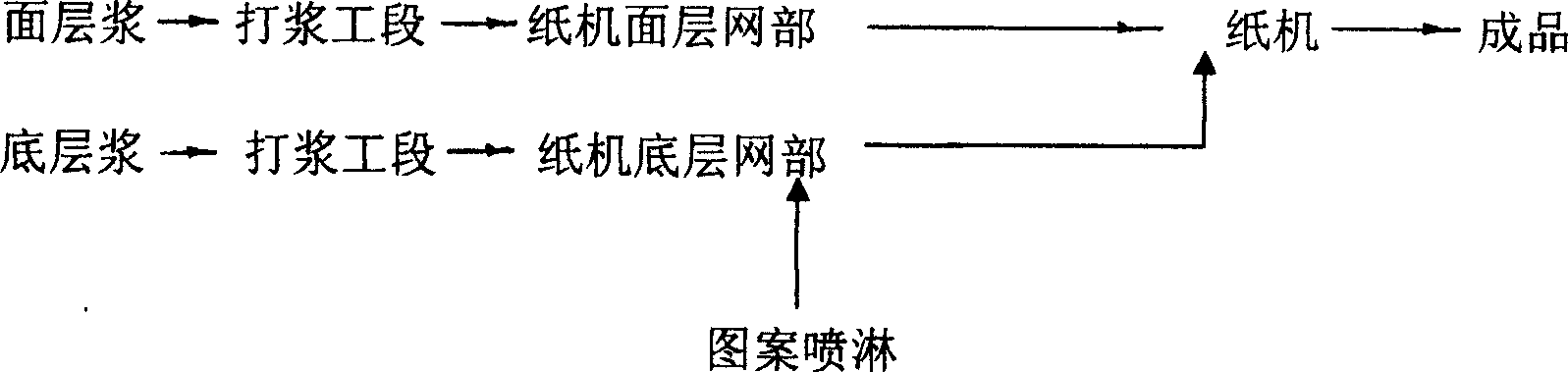

[0025] 1. Pulping

[0026] ① Face paper layer: The pulp board of the face paper layer is crushed by a hydropulper and beaten (if it is self-made pulp, it is directly beaten), and then it is batched, and the prepared pulp is sent to a paper machine for papermaking.

[0027] ②Bottom paper layer: The pulp board of the bottom paper layer is crushed by a hydropulper and beaten (if it is self-made pulp, it is directly beaten), and then it is batched, and the resulting pulp is sent to the paper machine for papermaking.

[0028] 2. Adding patterns

[0029] Personalized anti-counterfeiting patterns are sprayed between the surface and the bottom layer in the wire section of the paper machine through its unique flow delivery system.

[0030] 3. Papermaking

[0031] ① The top paper layer pulp and the bottom paper layer pulp made by papermaking are sent to the top wire and bottom wire of the paper machine for papermaking, and then pressed, dried, coated, and finally calendered.

[0032]...

Embodiment 2

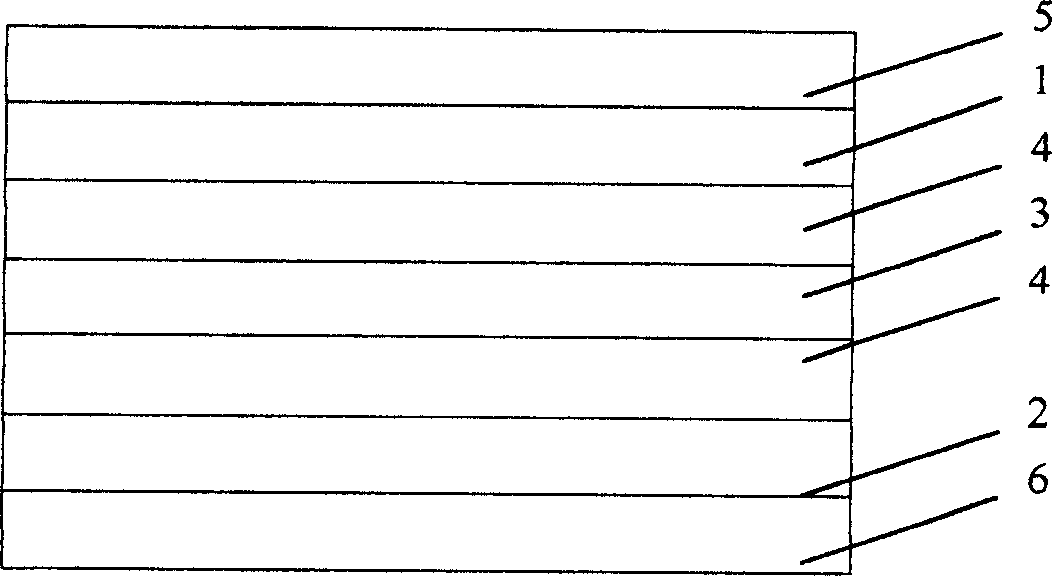

[0036] Anti-counterfeiting coated white cardboard is composed of surface paper layer, core paper layer and bottom paper layer. Its production method is as follows:

[0037] 1. Pulping

[0038] ① Face paper layer: The pulp board of the face paper layer is crushed by a hydropulper and beaten (if it is self-made pulp, it is directly beaten), and then it is batched, and the prepared pulp is sent to a paper machine for papermaking.

[0039] ② Core paper layer: The pulp board of the core paper layer is disintegrated or beaten after being crushed by a hydraulic pulper (if it is self-made pulp, it is directly deflated or beaten), and then it is batched, and the prepared pulp is sent to the paper machine for processing. Copy.

[0040] ③Bottom paper layer: The pulp board of the bottom paper layer is crushed by a hydraulic pulper and then beaten (if it is self-made pulp, it is directly beaten), and then it is batched, and the resulting pulp is sent to the paper machine for papermaking. ...

Embodiment 3

[0049] The process conditions are the same as in Example 2. After the paper sheet is formed, a layer of pattern is sprayed on the back side of the paper sheet, and the spray point can be selected before or after the back coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com