Shaft seal device used for ultra low specific rotating speed centrifugal fan

A technology of centrifugal fan and specific speed, which is applied to components, mechanical equipment, machines/engines, etc. of pumping devices used for elastic fluids, and can solve the problem of inability to achieve small or even zero leakage, large vibration of fans and units , Fan impeller diameter and other issues, to shorten the installation and maintenance time, improve life, reduce the effect of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

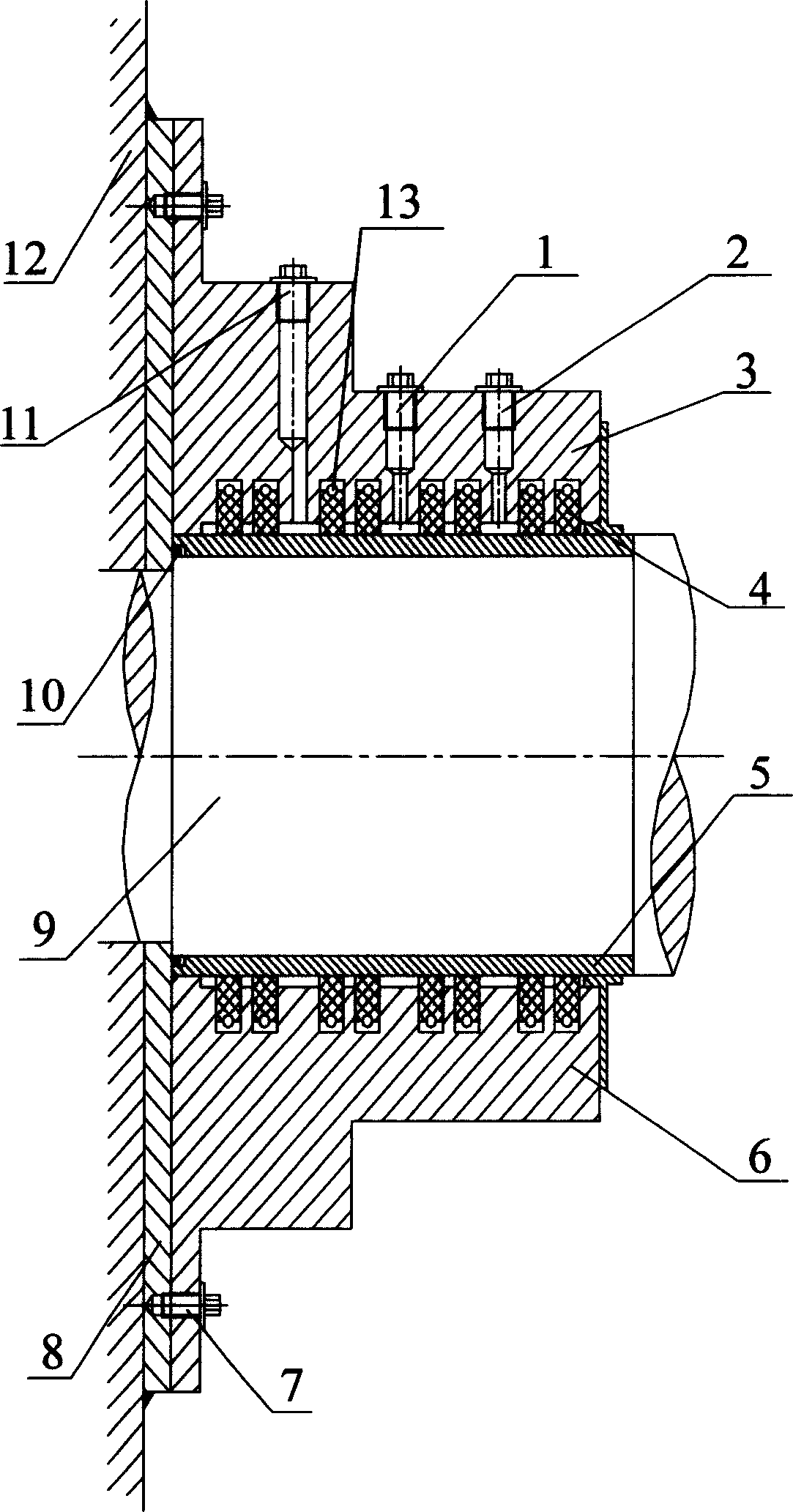

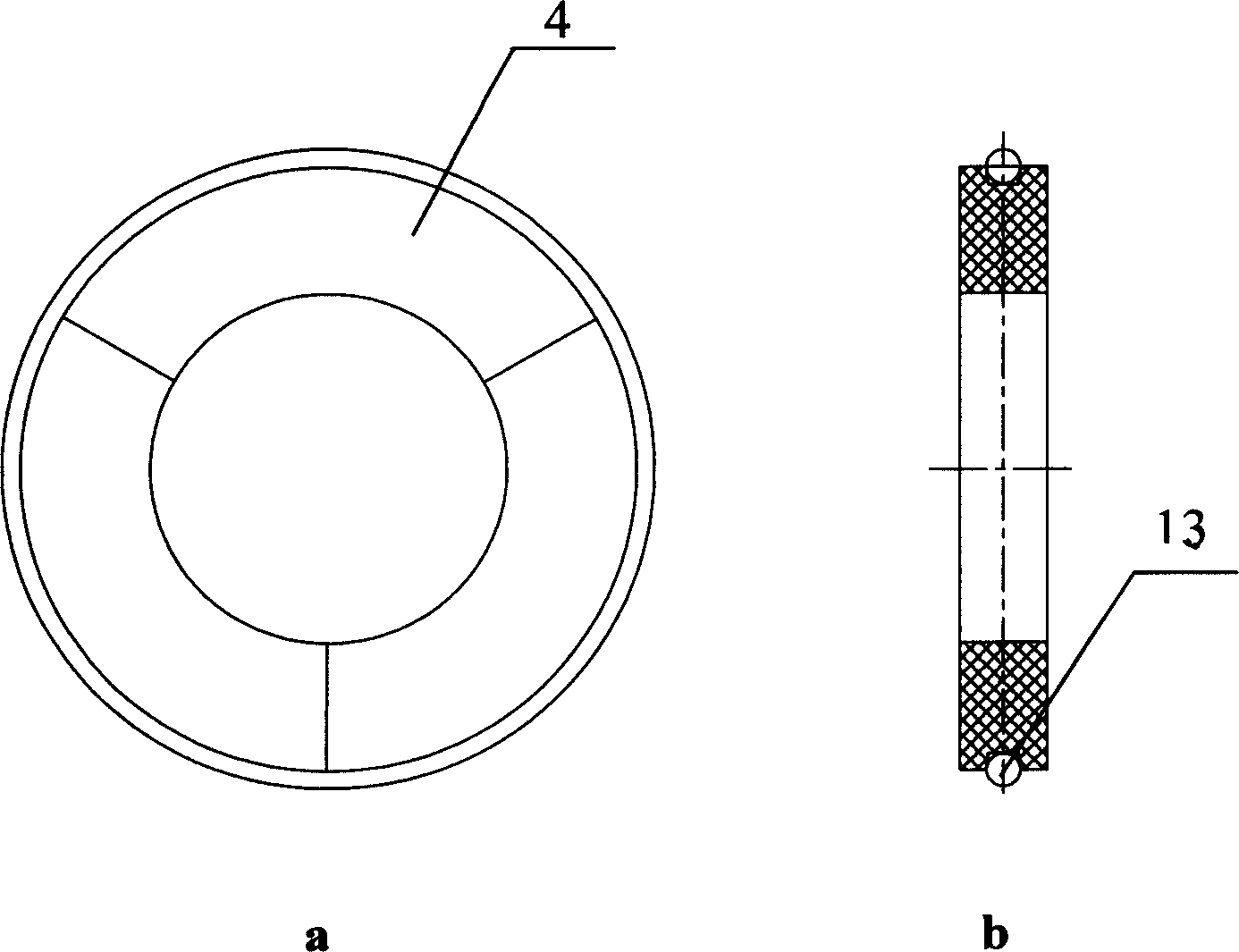

[0017] The structure of the shaft sealing device used for the ultra-low specific speed centrifugal fan of the present invention is as follows: figure 1 As shown, a horizontally split structure is adopted, and the shaft sleeve 5 is installed on the fan main shaft 9 through interference fit. The upper cover plate 3 and the lower cover plate 6 fixed on the outside of the shaft sleeve 5 are semicircular pairs of upper and lower sides, and the upper and lower cover plates are respectively connected by The bolt 7 is connected with the flange 8, and the flange 8 is installed on the rear end cover 12 of the fan casing by welding. The insides of the upper cover plate 3 and the lower cover plate 6 in contact with the shaft sleeve 5 are respectively provided with annular grooves for installing the sealing ring 4 . The sealing rings 4 are in gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com