High temperature acidified mutual solvent

An acidifying mutual solvent, high temperature technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem that surfactants can not play the role of anti-corrosion, anti-demulsification, demulsification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The composition, preparation process and performance parameters of the present invention will be described in detail below in conjunction with examples.

[0024] (1) Raw material performance requirements

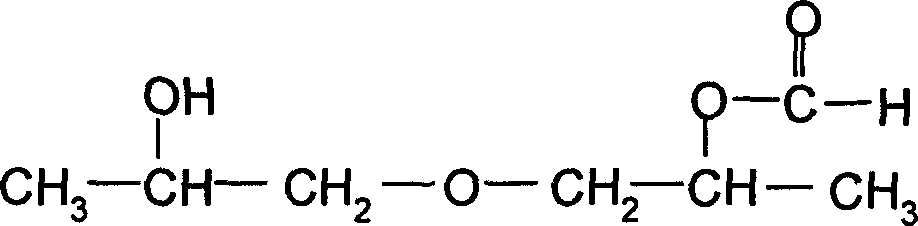

[0025] The effective content of dipropylene glycol monomethyl ester is greater than 96%;

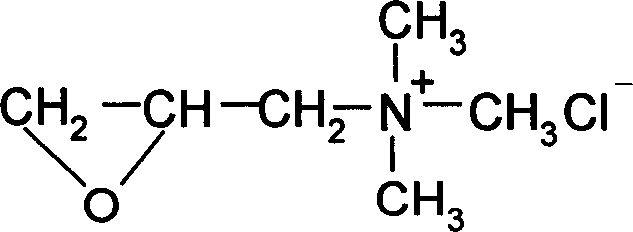

[0026] The effective content of 2,3 epoxypropyltrimethylammonium chloride is greater than 96%;

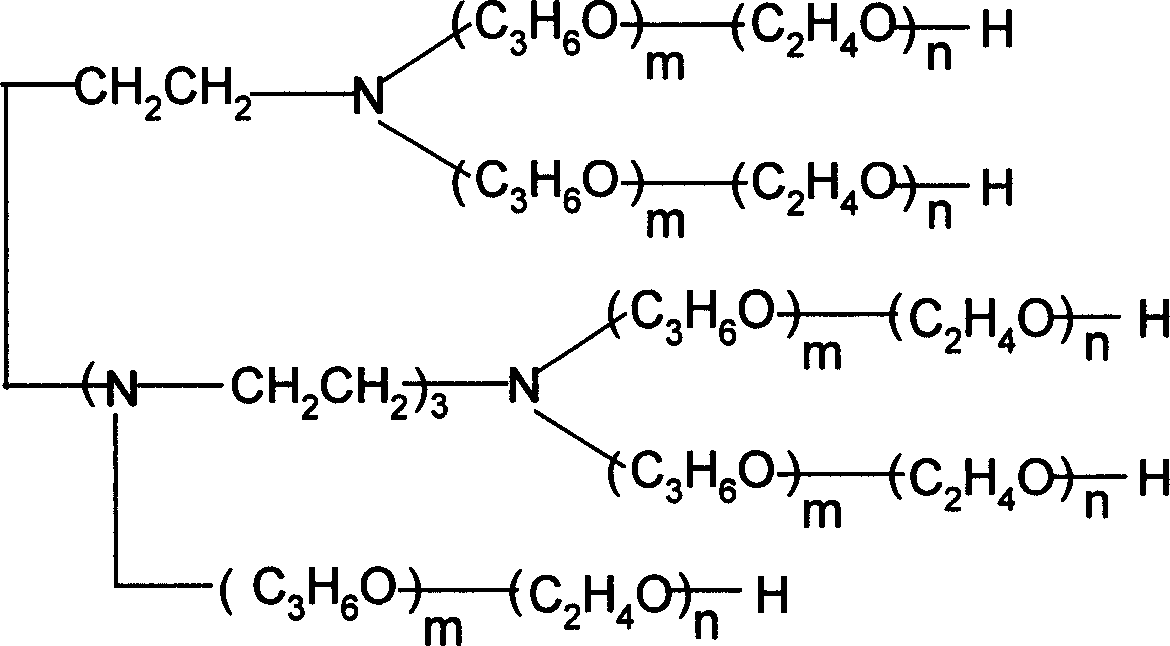

[0027] The effective content of polyoxyethylene polyoxypropylene tetraethylenepentamine is greater than 93%.

[0028] (2) Preparation examples and performance parameters of high-temperature acidified mutual solvents

[0029] 1m to the activated 3 Add 220kg of water, 460kg of dipropylene glycol monomethyl ester and 280kg of polyoxyethylene polyoxypropylene tetraethylenepentamine into the emulsifier, raise the temperature to 50°C, and stir until completely dissolved. Then add 40kg2,3 glycidyltrimethylammonium chloride while stirring, and stir until a uniform transparent solution is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com