Method and device for multiplexing and demodulating sensor based on optical fiber grating in long cycle

A technology of fiber grating and demodulation method, applied in the field of optical fiber sensing, can solve the problems of multiplexing and demodulation method of LPGP that no one has proposed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

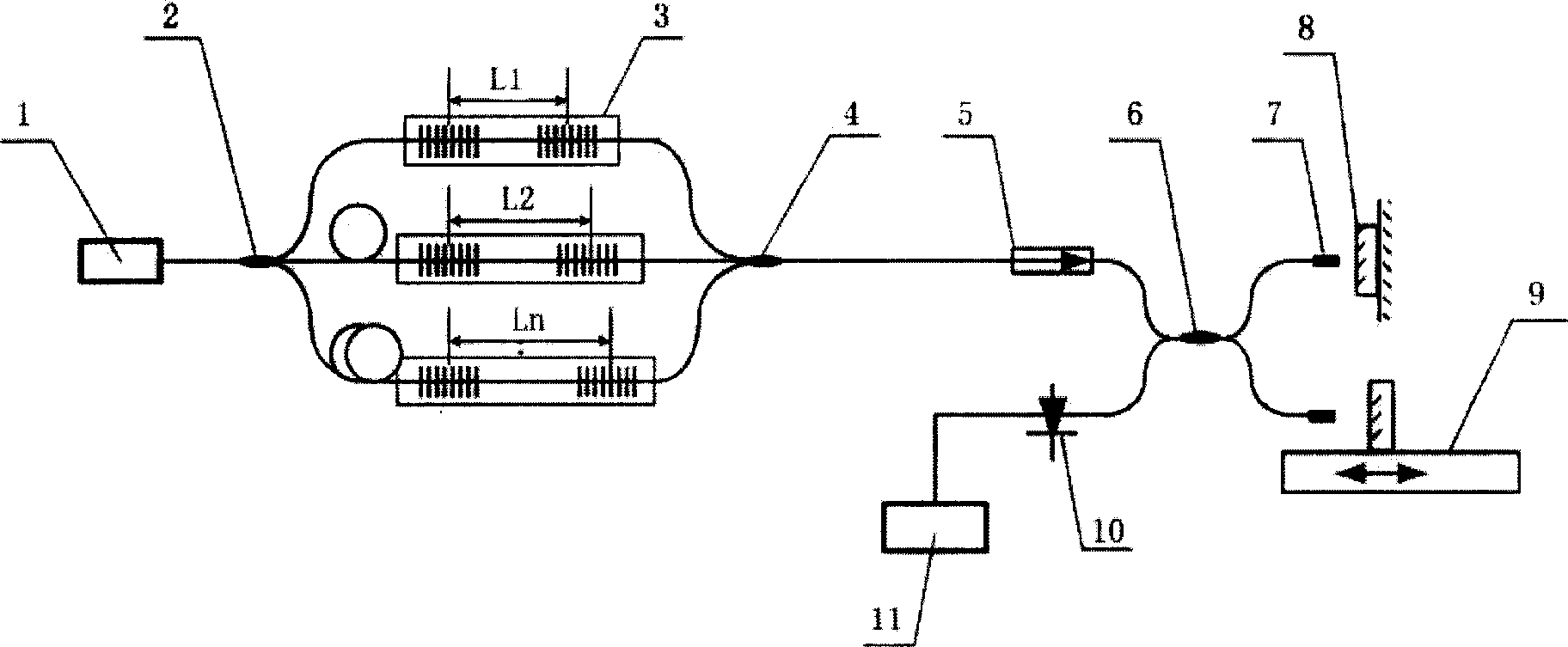

[0018] Such as figure 1 As shown, the input ends of multiple parallel-connected LPGP sensors 3 with different grating center distances are respectively connected to the optical signal of the broadband light source 1 through the optical fiber coupler 2 , and the output end is connected to the optical signal of another optical fiber coupler 4 . Optical one-way isolator 5 input end is connected with optical signal of fiber coupler 4, and its output end is connected with the input end of photodiode 10 and one end optical signal of 3-dB fiber optic coupler 6, and the output end of photodiode 10 is connected with data The acquisition card 11 is electrically connected. The other end of the 3-dB fiber optic coupler 6 is respectively connected to the optical signals of two fiber collimators 7, and two mirrors 8 are arranged corresponding to the positions of the two fiber collimators 7, one of which is controlled by a stepping motor 9 Its position moves. The above-mentioned multiple L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com