Thread cutting insert

A thread cutting and blade technology, applied in cutting blades, thread cutting tools, tools for lathes, etc., can solve the problems of high-frequency vibration, increased cutting resistance, and reduced surface precision of finishing, and achieve the purpose of suppressing the increase of resistance big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

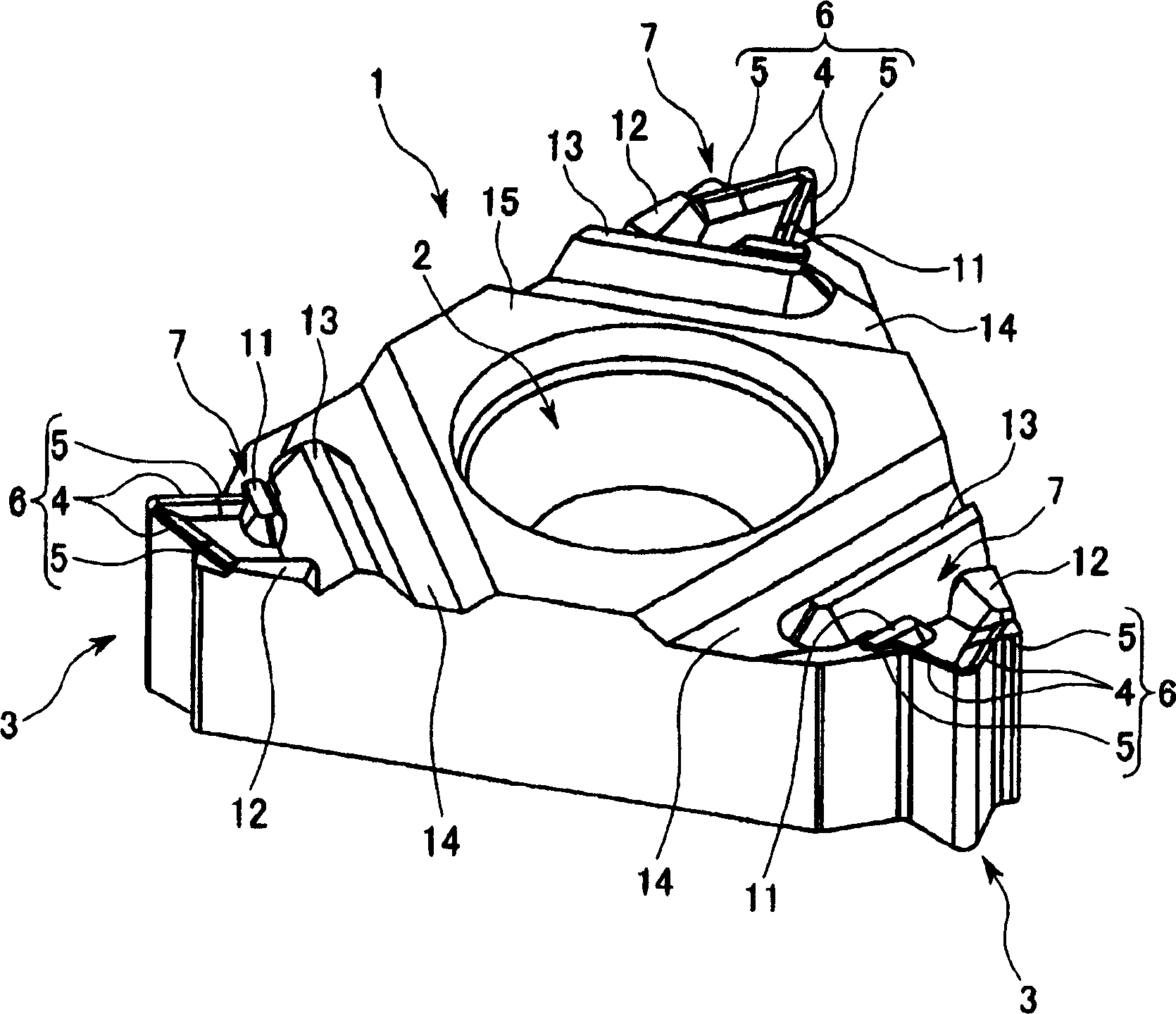

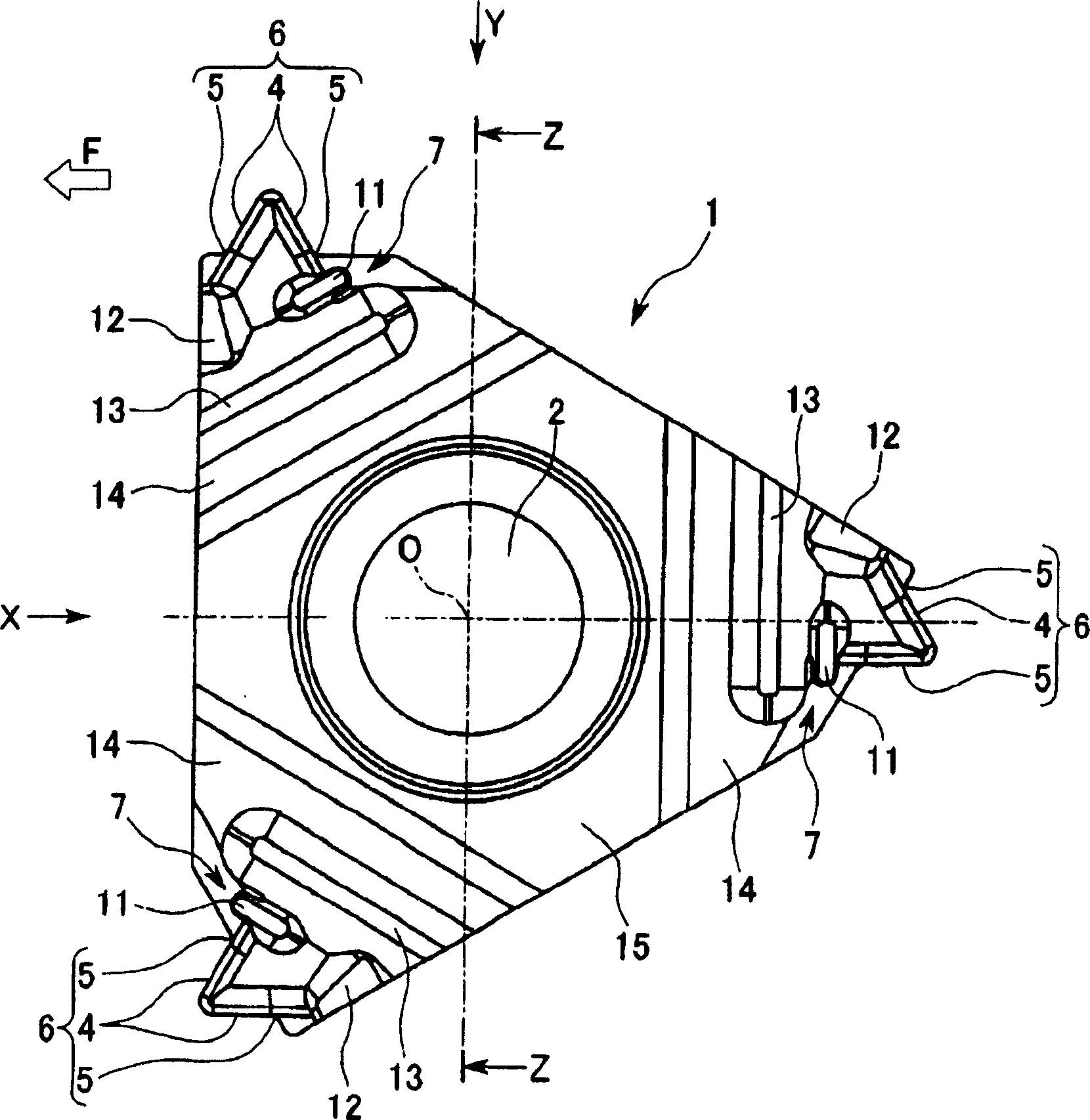

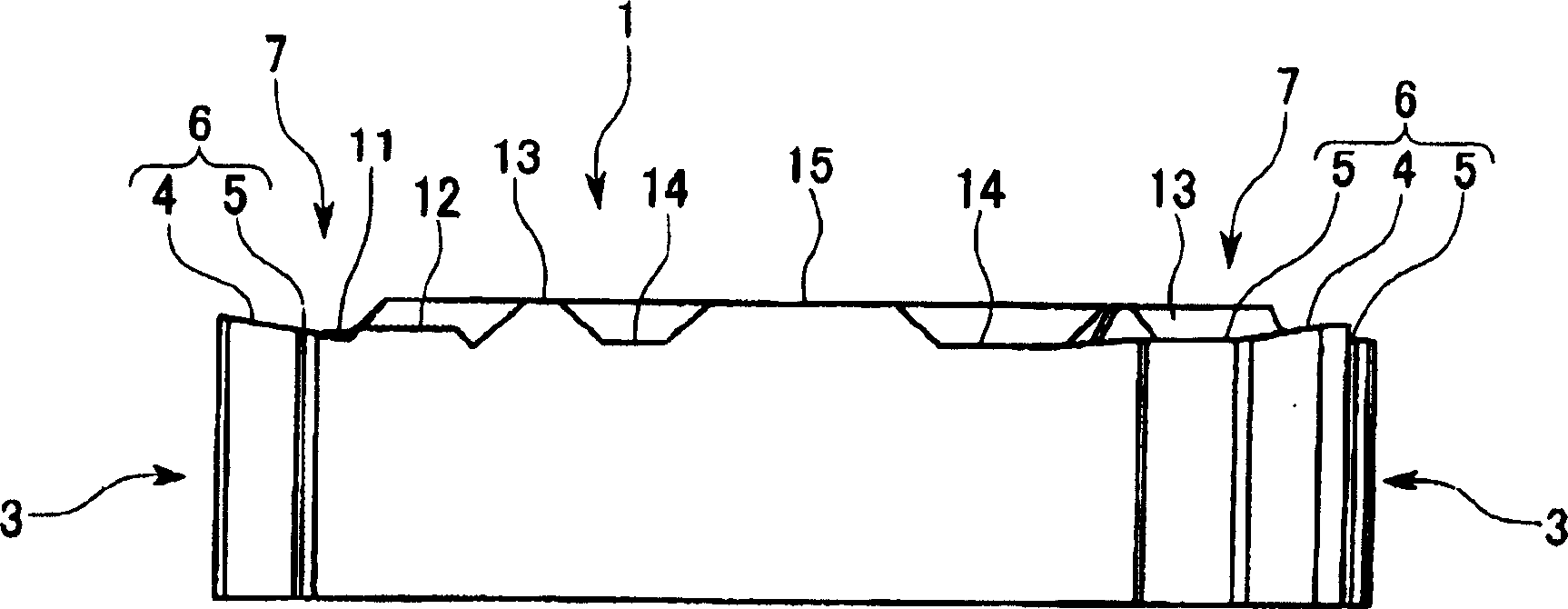

[0036] Figure 1 to Figure 14 An embodiment of the present invention is shown. In this embodiment, the insert body 1 is made of a hard material such as cemented carbide, such as figure 2 As shown in the flat shape forming a roughly equilateral triangle, in the center of the upper and lower surfaces constituting a roughly equilateral triangle, there are openings along the thickness direction ( figure 1 , 3 Up and down directions in ~5. Hereinafter referred to as the blade thickness direction) through the circular mounting hole 2 of the blade main body 1 , the blade main body 1 is a 120° rotationally symmetrical shape about the center line O of the mounting hole 2 . Also, in a plan view along the center line O, the corners of the above-mentioned equilateral triangle formed by the blade body 1 are as follows: figure 2 As shown, a cut is made in a manner substantially perpendicular to one of the edge parts intersecting at the corner, and at the part of the cut, as Image 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com