Horizontal hydraulic pressure full automatic packing machine

A fully automatic and hydraulic technology, applied in the field of balers, can solve the problems of inconvenient feeding of light foam materials, time-consuming, low production efficiency, etc., and achieve the effects of high production efficiency, energy saving, and increased packaging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

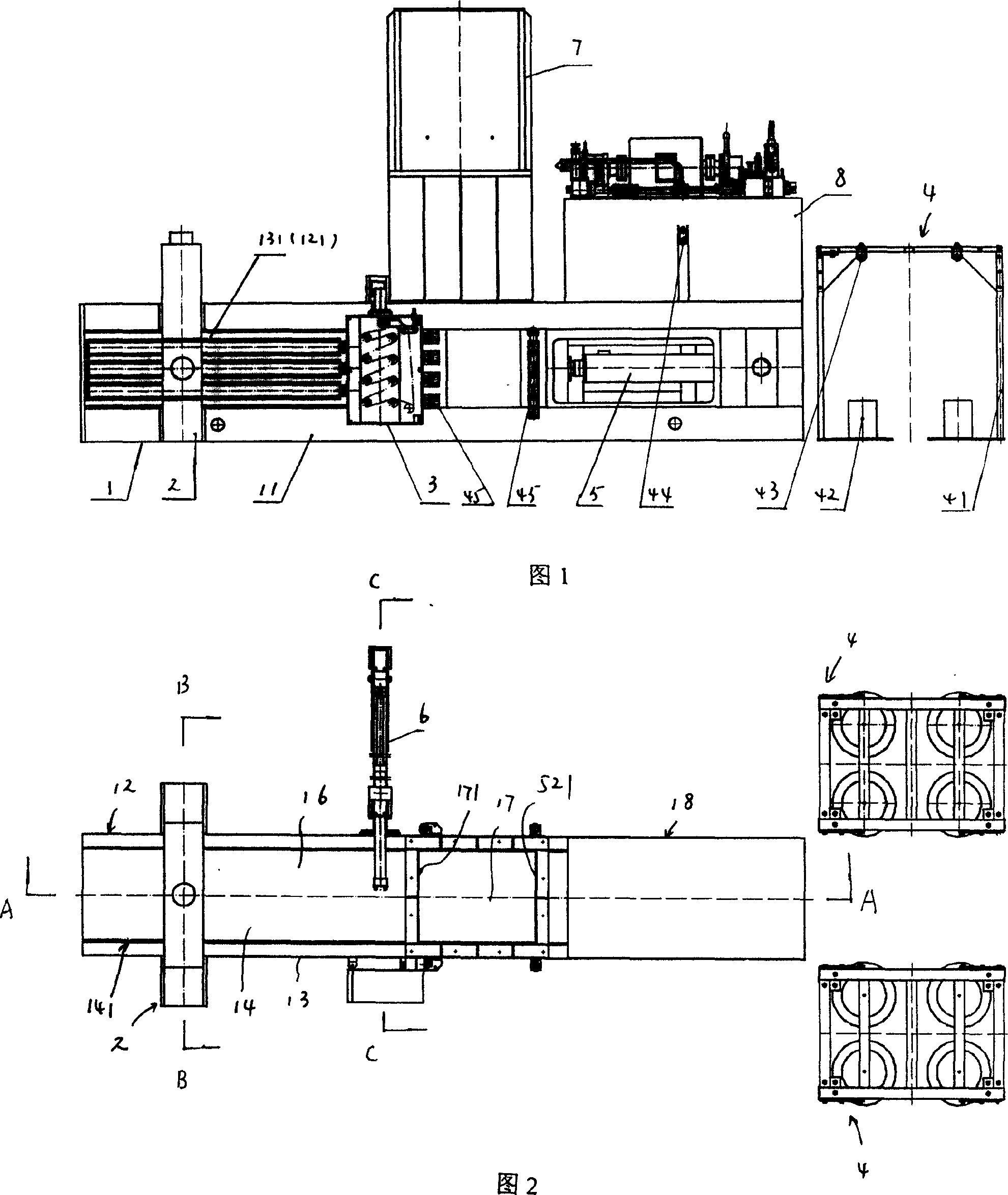

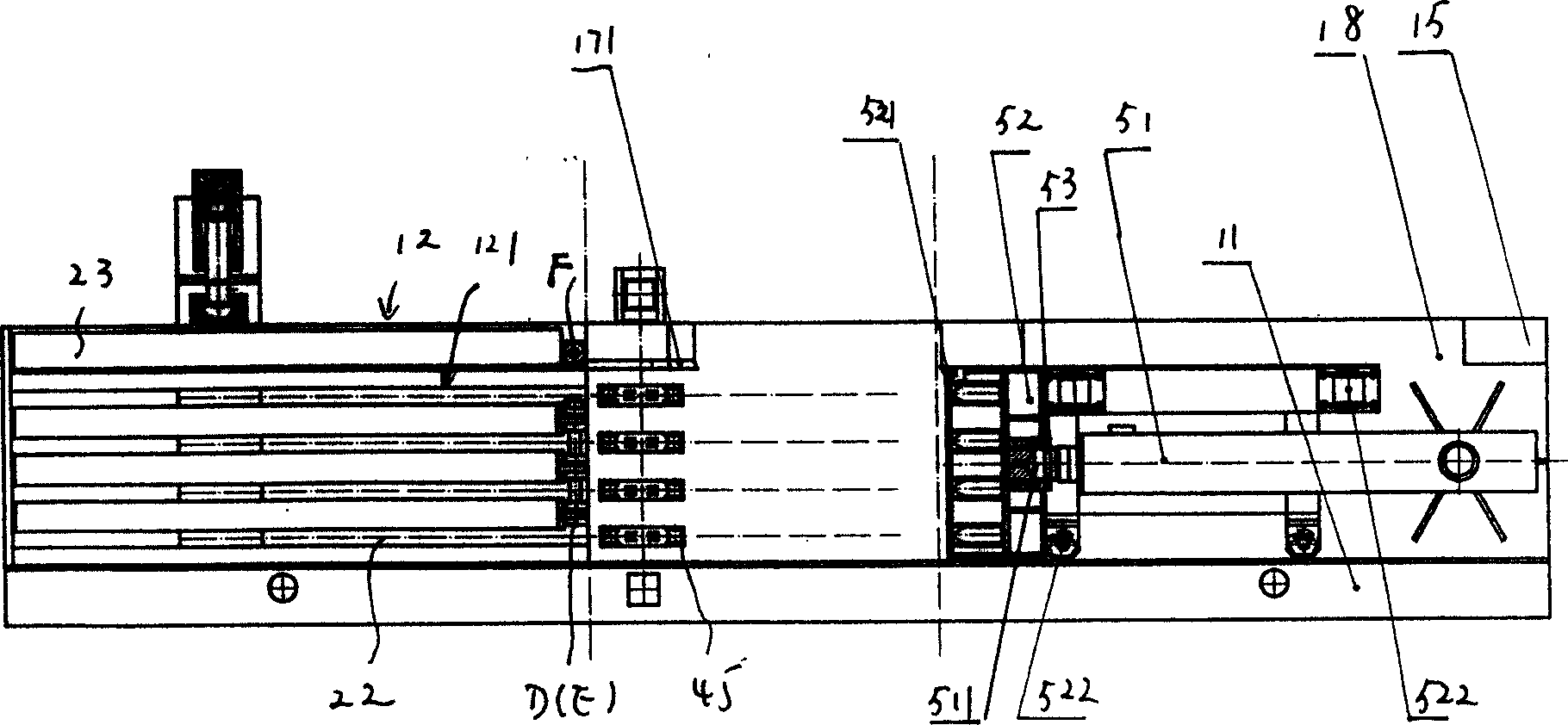

[0025] Referring to Figures 1 to 3, the horizontal hydraulic fully automatic baler of the present invention is mainly composed of three parts: a main engine, an electrical and optical control system and a hydraulic system.

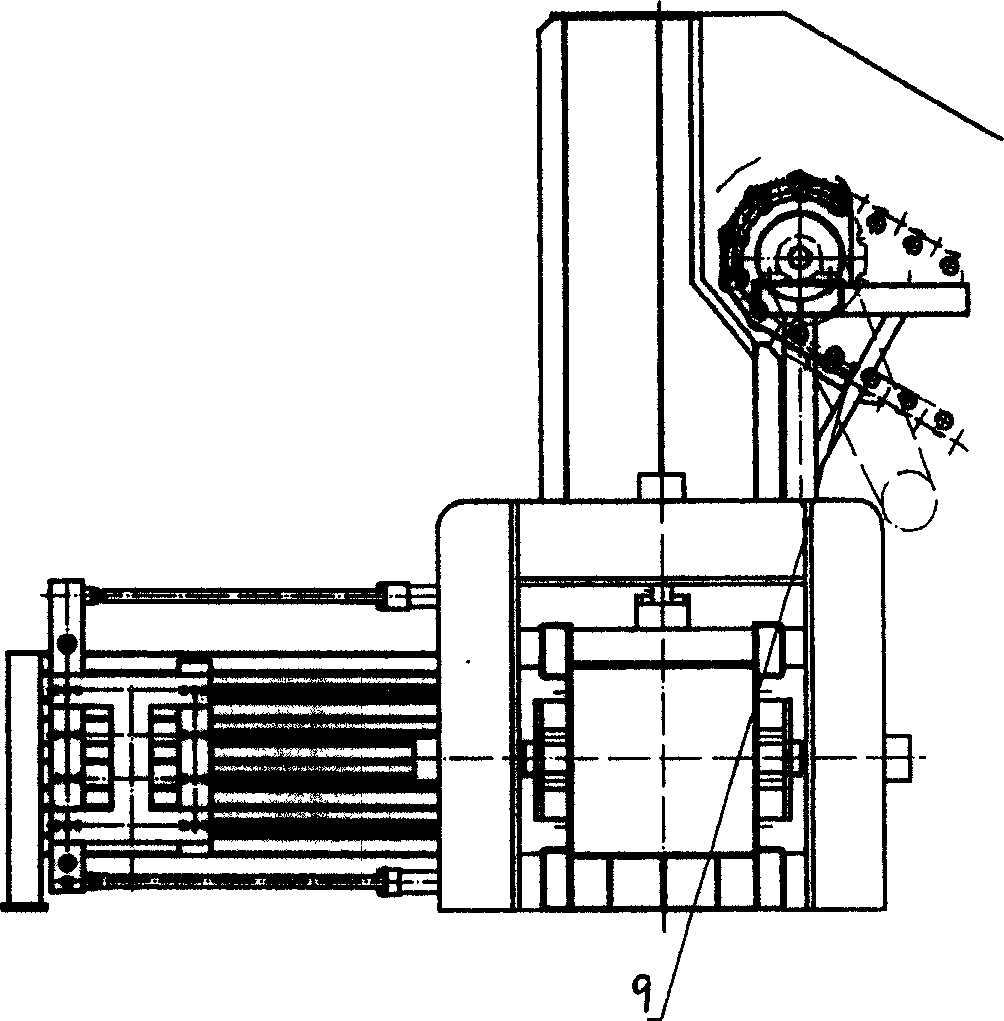

[0026] The main machine is composed of a chassis 1, a necking device 2, a wire twisting and cutting device 3, a wire guide device 4, a pressing device 5, a wire pushing device 6, a feeding hopper 7, a hydraulic oil station 8 and a feeding device 9, etc. .

[0027] The said chassis 1 is the framework of the host. It consists of base 11, left wallboard 12, right wallboard 13, front top board 14 and rear support 15. The middle of the cabinet 1 is a compression chamber 17 with an open top, the front section is a front cabinet 16 with an open front top plate, and the rear section is a rear cabinet 18 with a rear support.

[0028] The compression chamber 17 is a place for stacking and compressing packing materials. The front edge of the top opening of the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com