Composite bearings

A technology of composite bearings and polymers, which is applied in the direction of shafts and bearings, bearing components, mechanical equipment, etc., and can solve problems such as unsuitable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

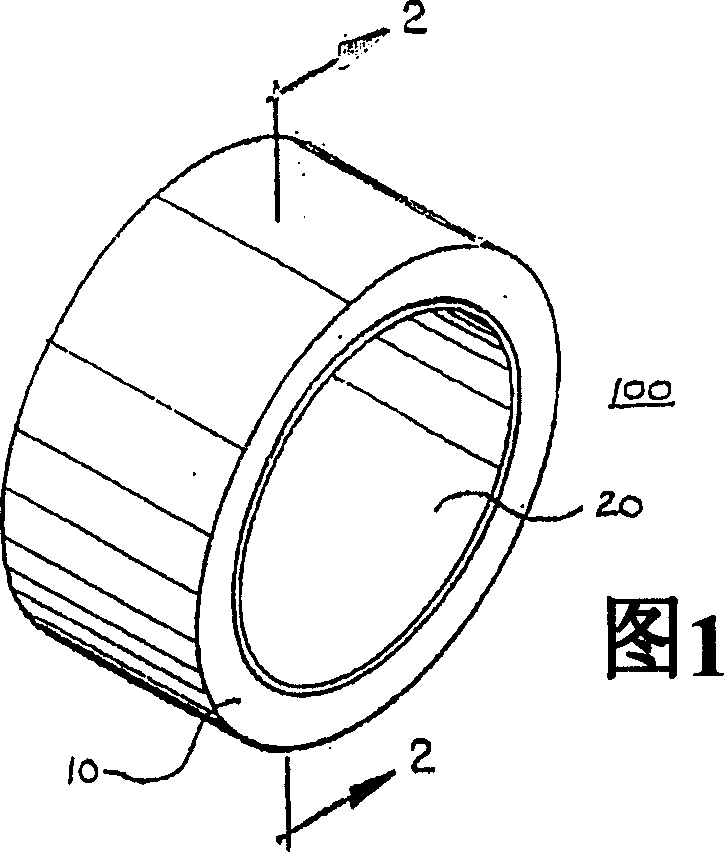

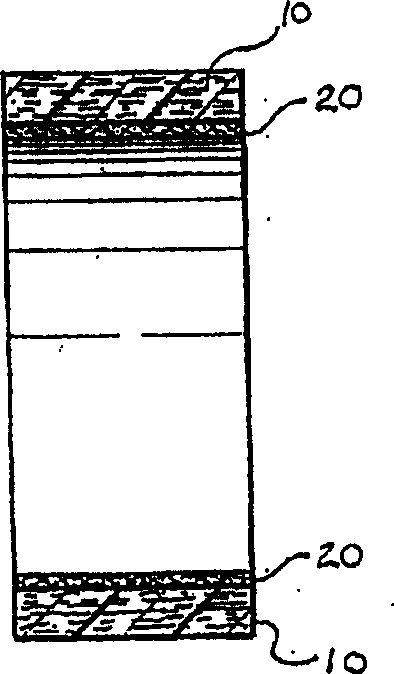

Image

Examples

example 1

[0026] Example 1 (control)

[0027]PTFE-Dacron fiber wound composite bearings (1620-11 MLG bearings manufactured by Glacier Glock, Thorofare, NJ), without PTFE particles or wetting agents, were tested on a HOT test machine using the following test conditions Test: Pressure = 4300 psi, Oscillation = 10° (total) + / - 5° (from center), Speed = 200 cycles / min, Rigid Shaft Polish = 7 microinches AA and approximately 100-200 Rockwell "B" Surface hardness. This test was run as a "control standard" for approximately 90 hours, resulting in a wear depth of 0.017 inches (0.043 cm) at 1.1 million cycles.

example 2

[0029] Under the same test conditions, a HOT test was performed on a bearing having the bushing composite and construction of Example 1, but also including PTFE particles and wetting agent within the epoxy bushing, resulting in 0.007 inches (0.018cm) of wear depth.

[0030] Wetting of the PTFE particles was carried out as follows. Using an industrial "Jiffy" or "Rapid Propeller Mixer" to mix the ingredients including NADIC® Methyl Anhydride (8 kg), Teflon® #62 PTFE Fine Powder (2 kg) and TroySol TM Mixture of S366 (0.2 kg) for 10 minutes. After 24 hours, the mixture was stirred again for another 10 minutes. The resulting dispersion was stirred for an additional 15 minutes with Epon 828 epoxy resin (9 kg) and BDMA (0.2 kg). A PTFE-Dacron® fiber wound composite bearing was thus fabricated as a 1620-11 test bearing having the bushing composite and construction of Example 1, but which also included PTFE particles and wetting agent within an epoxy bushing .

[0031] Bearings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com