Positioning dyeing transmission type antifake white paperboard and producing method thereof

A manufacturing method and technology of white cardboard, applied in chemical instruments and methods, paper/cardboard layered products, paper, etc., can solve the problems of high consumption of dyes and imitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

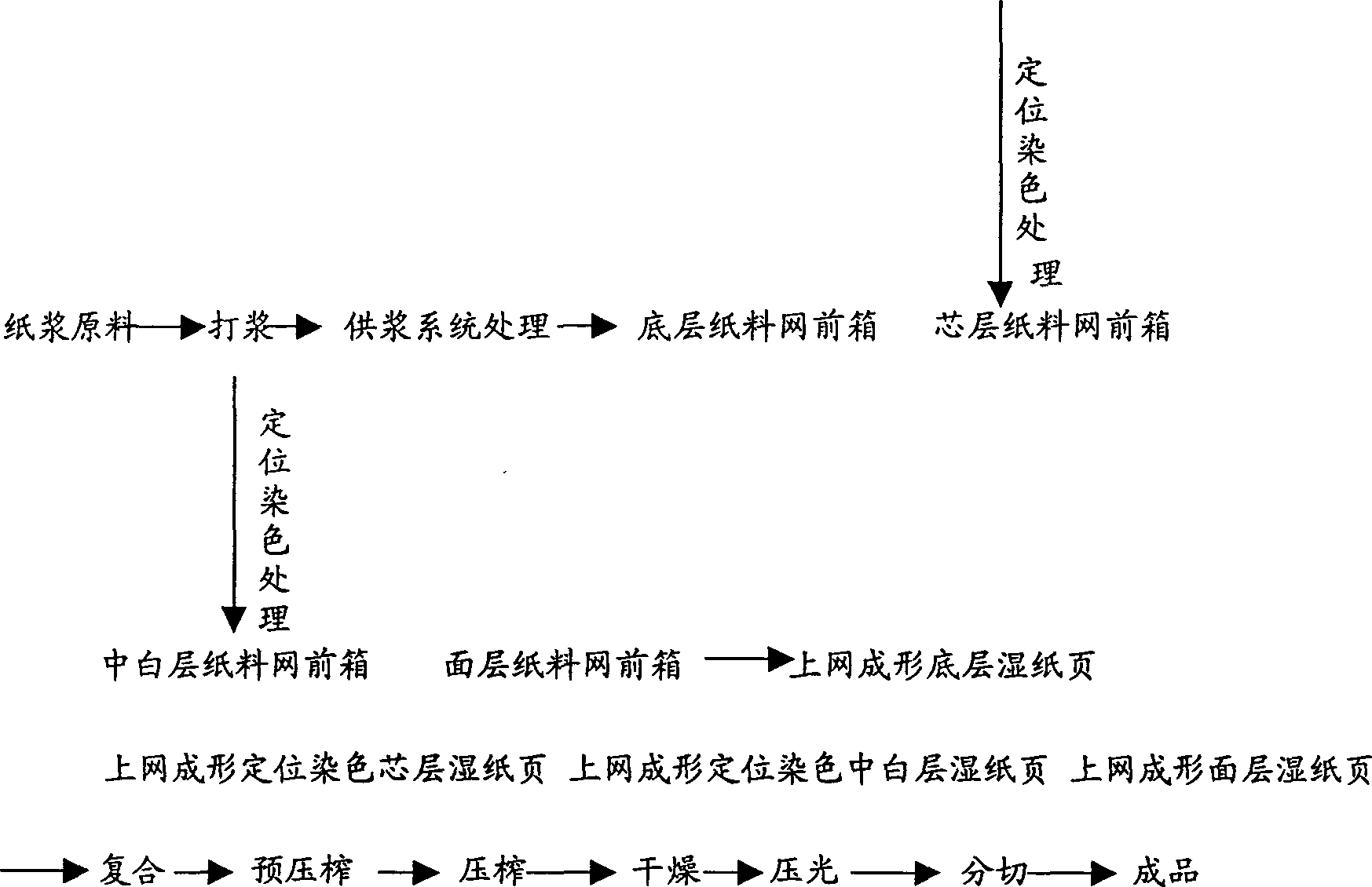

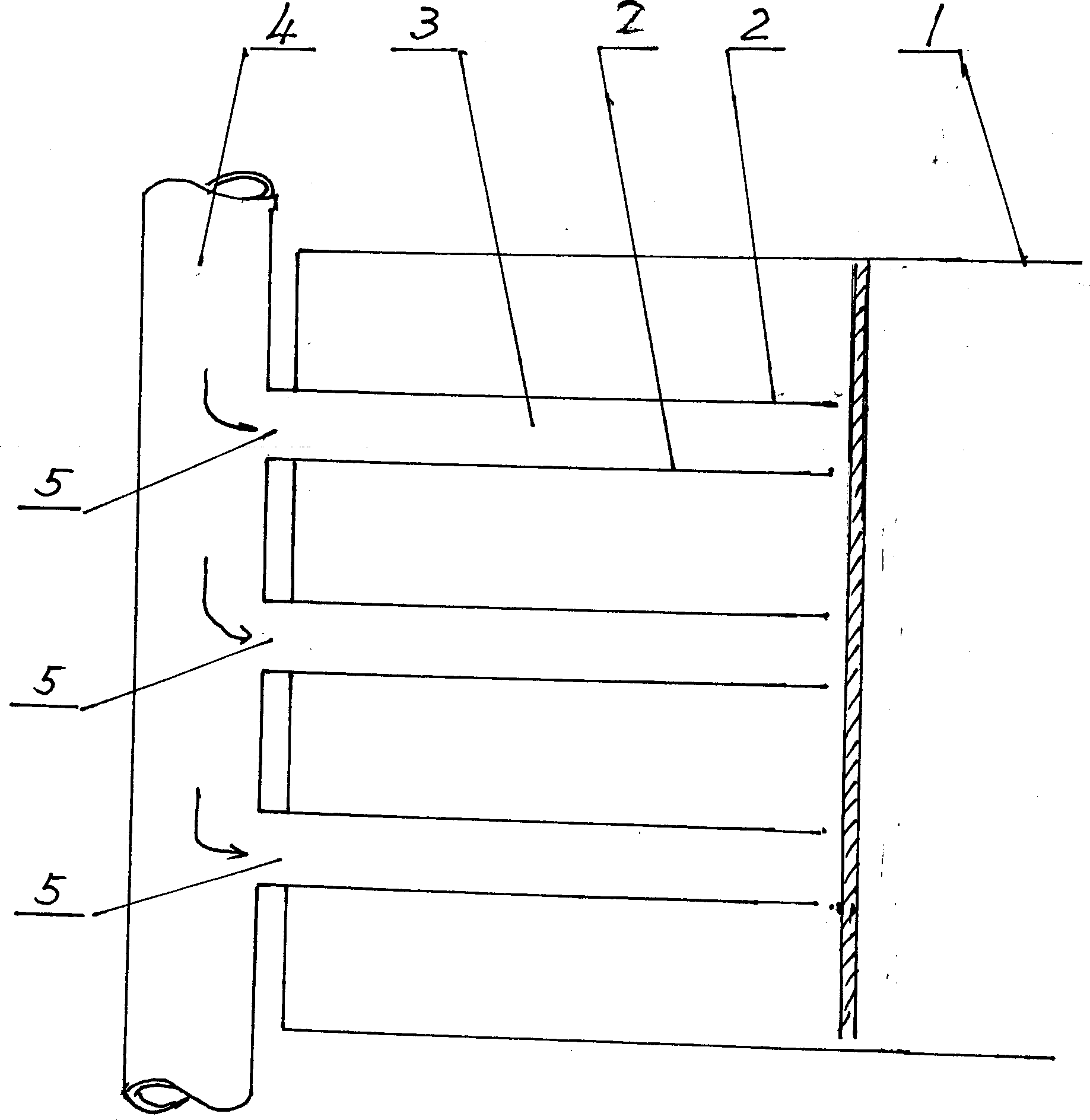

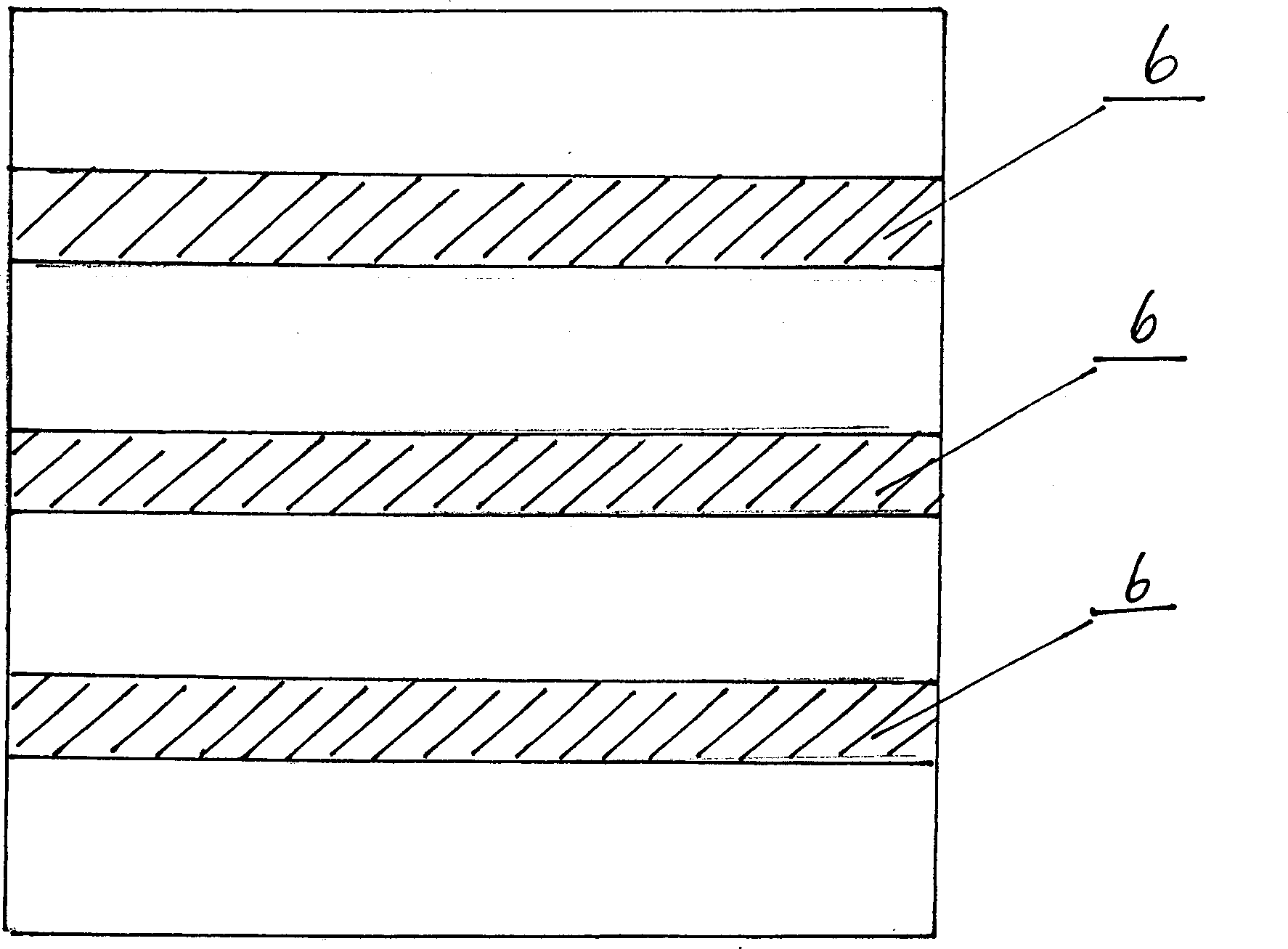

[0021] see figure 1 with figure 2 , a position dyeing transmissive anti-counterfeiting white paperboard and a manufacturing method thereof, a white paperboard made by a multi-net multi-cylinder paper machine, at least composed of three or more pulp layers, wherein the white paperboard composed of four pulp layers, its The surface pulp is bleached coniferous wood kraft pulp, the middle white pulp is waste paper deinked pulp, the core pulp is mixed waste paper deinked pulp, and the bottom pulp is waste white paper edge pulp. Different pulps are beaten separately. After the pulp system is processed, the paper materials with a certain pulp concentration are sent to the headbox of the bottom paper material, the headbox of the core layer paper material, the headbox of the middle white layer paper material and the headbox of the surface layer paper material, and are formed on the Internet , it is characterized in that: the core layer paper material and the middle white layer paper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com