Consequent water inlet valve

A water inlet valve, forward technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of valve top opening, lower reliability, soft material wear, etc., to overcome friction damage, simple structure, and close reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

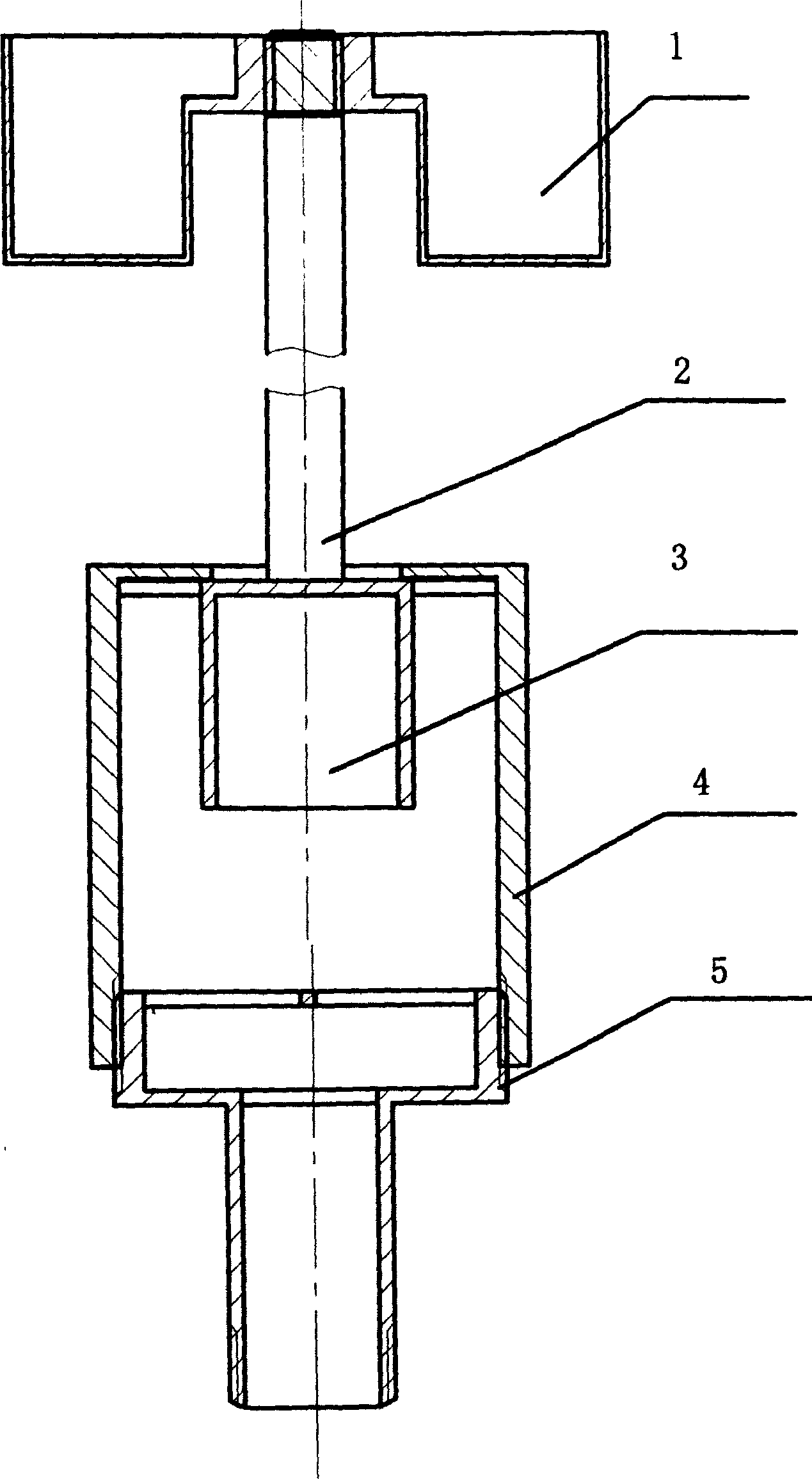

Image

Examples

Embodiment Construction

[0009] The upper and lower valve sleeves, counterweight container and valve core can be made by plastic injection molding, metal stamping, ceramic sintering and other methods. If the cross frame at the top of the lower valve sleeve is made of plastic and metal materials, it can be welded; if ceramic materials are used, the two blanks are first prepared, then the cross is bonded, and finally fired. Fill the valve core with buoyant material or make a closed space under the valve plate. After the valve core is put into the upper valve sleeve, the two valve sleeves are screwed together, and the top of the valve stem is then screwed into the counterweight container.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com