Non-aqueous electrolyte secondary battery

A non-aqueous electrolyte and secondary battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems such as curing, and achieve the effect of improving quality and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] (i) Production of positive electrodes

[0069] Solid solution nickel hydroxide containing a certain amount of cobalt and aluminum is used as a raw material of the positive electrode active material. More specifically, solid solution nickel hydroxide (nickel hydroxide A) and lithium hydroxide having an average particle diameter of 7 µm were mixed, followed by firing at 950°C. The resulting product was cooled slowly to 100°C for 12 hours. Thereby obtaining secondary particles of lithium-nickel composite oxide (composition: LiNi 0.8 co 0.15 al 0.05 o 2 ), called particulate matter A. Meanwhile, granular substance B was prepared in the same manner as in the production of granular substance A except that solid solution nickel hydroxide (nickel hydroxide B) having an average particle diameter of 0.3 μm was used.

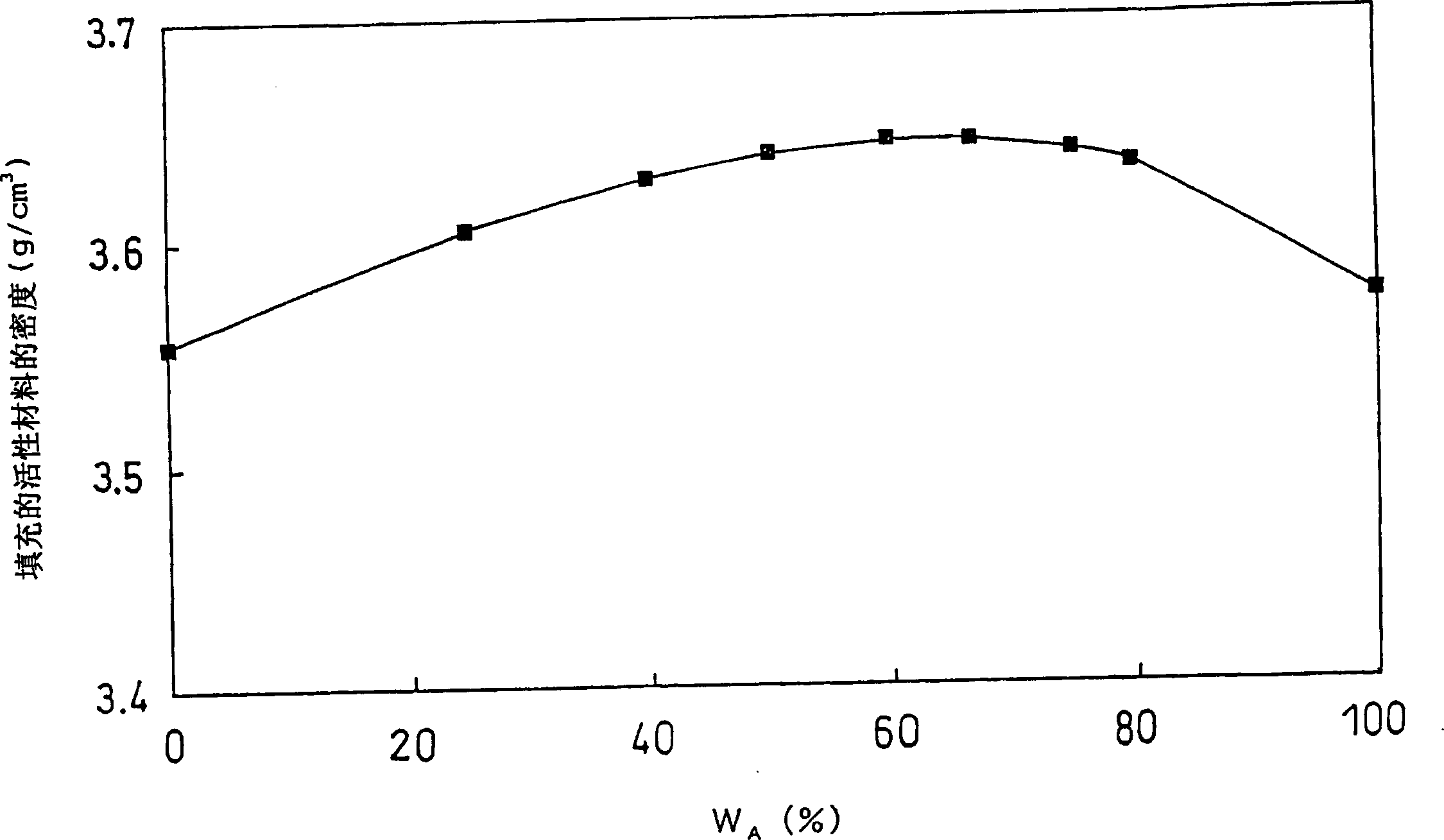

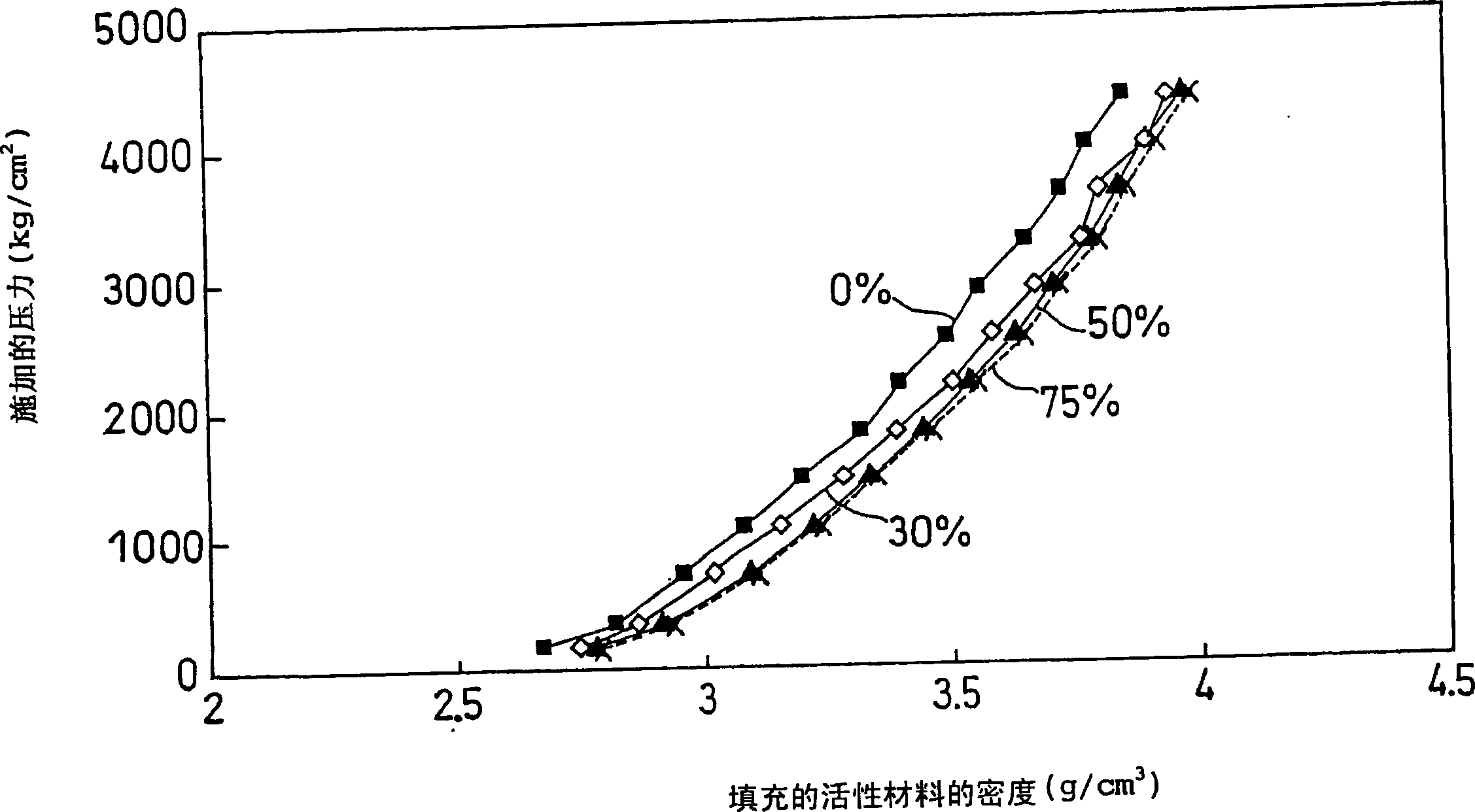

[0070] The weight ratio of the particulate matter A and B is A:B=70:30. Particulate matter A has an average particle size of 20 microns. The average particl...

Embodiment 2 to 4

[0083] Except by changing the average particle diameter of solid solution nickel hydroxide B to 1 micron, 1.5 micron and 3 microns respectively, so that the average particle diameter of particulate matter B is changed to 3 microns, 5 microns and 10 microns respectively, according to the embodiment Batteries of Examples 2, 3 and 4 were produced in the same manner as in 1.

Embodiment 5 to 7

[0085] Except that by changing the average particle size of solid solution nickel hydroxide A to 3 microns, the average particle size of particulate matter A changes by 10 microns, and by changing the average particle size of solid solution nickel hydroxide B to 1 micron and 1.5 microns and 2.5 microns, so that the average particle size of the particulate matter B was changed to 3 microns, 5 microns and 8 microns, respectively, and the batteries of Examples 5, 6 and 7 were produced in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com