High-temperature and strength resistant molybdenum non-crystalline alloy

An amorphous alloy, high-temperature-resistant technology, applied in the field of multi-element molybdenum-based alloys, can solve problems such as high melting temperature, difficulty in amorphous alloys, and increased material preparation costs, and achieve good red hardness, high thermal stability and The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Mo 50 Si 35 co 15 Alloy (the nominal composition of the alloy is atomic percentage, at.%, the same below).

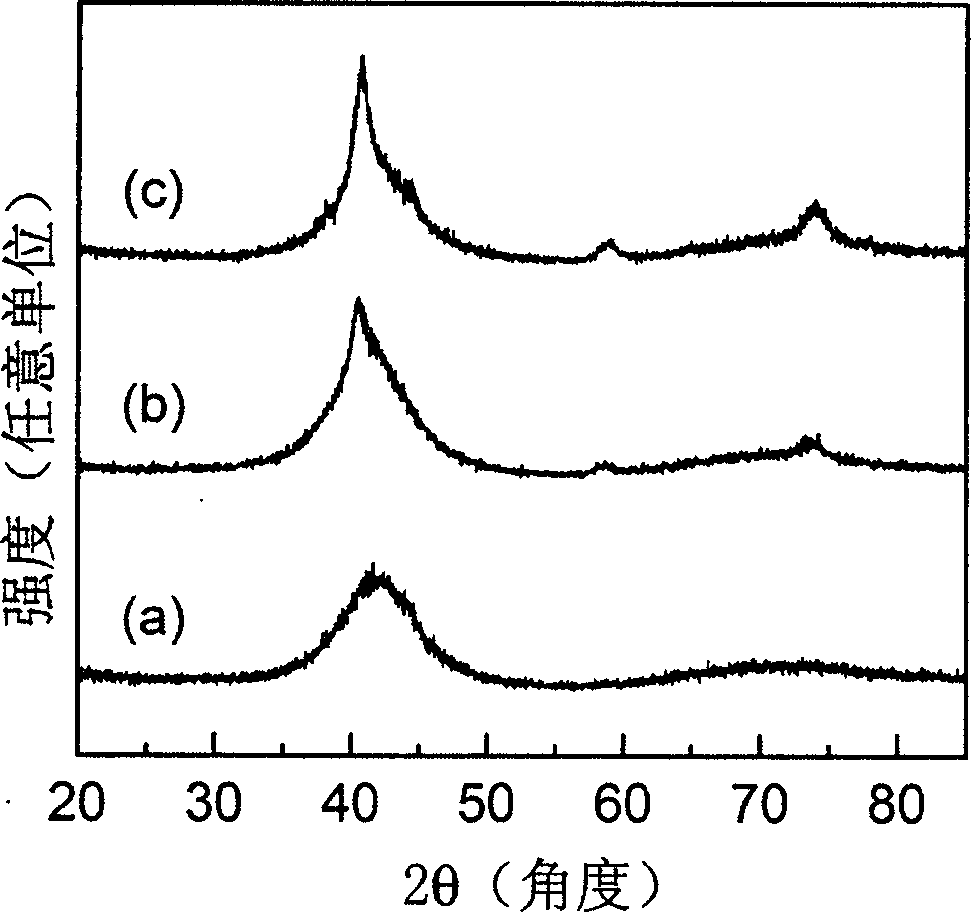

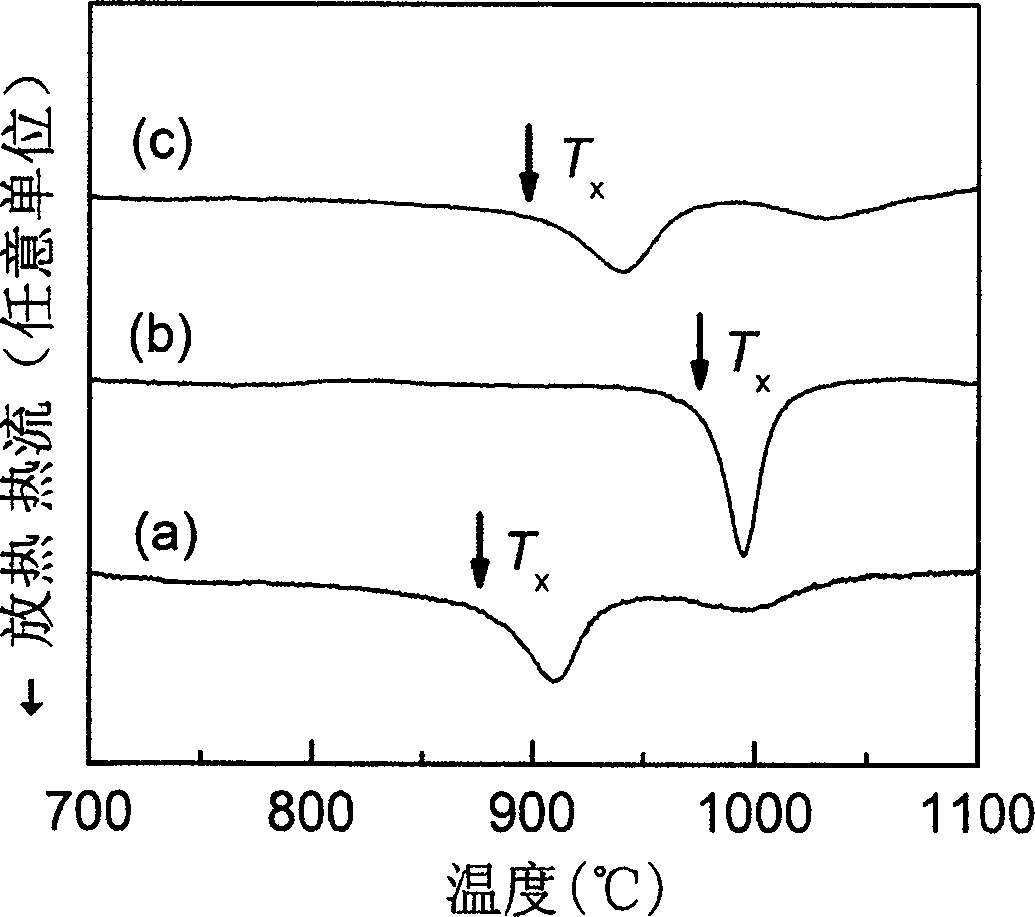

[0059] Using commercially available Mo, Si, and Co elemental powders as starting materials, the purity is higher than 99.5% (weight percentage, the same below), and the average particle size is less than 75 m, and the nominal composition is Mo 50 Si 35 co 15 powder mixture. The powder mixture and GCr15 steel balls are filled in a quenching ball mill tank under the atmosphere of high-purity Ar gas (99.99%) according to the weight ratio of balls and materials of 5:1. The closed ball mill jar was installed on a SPEX 8000 high-energy ball mill for grinding. After the powder mixture was mechanically ground for 48 hours, no obvious crystal diffraction peaks were observed in the x-ray diffraction spectrum (XRD, the same below), and a diffraction peak of a typical amorphous structure was formed at a diffraction angle of 30-55°; On the thermal analysis (differentia...

Embodiment 2

[0061] Mo 60 Si 28 co 12 alloy

[0062] Mo 60 Si 28 co 12 The preparation of alloy starting materials and the mechanical alloying process are the same as in Example 1. XRD, SEM, DSC analysis process is identical with embodiment 1. Mo formed by mechanical grinding for 48 hours 60 Si 28 co 12 The XRD spectra and DSC curves of alloy powder samples are shown in figure 1 (b) and figure 2 (b). After the powder mixture was mechanically ground for 48 hours, typical diffuse peaks of the amorphous phase and crystal diffraction peaks of the Mo solid solution were observed in the XRD spectrum; an obvious exotherm caused by crystallization could be observed on the DSC curve of the ball-milled powder reaction, these evidences indicate that mechanical milling forms the alloy as a mixture of crystalline and amorphous phases. Use professional software to perform peak fitting on the XRD spectrum, separate the diffraction peaks of the crystal and amorphous phases from the original ...

Embodiment 3

[0064] Mo 70 Si 21 co 9 alloy

[0065] Mo 70 Si 21 co 9 The preparation of alloy starting materials and the mechanical alloying process are the same as in Example 1. XRD, SEM, DSC analysis process is identical with embodiment 1. Mo formed by mechanical grinding for 48 hours 70 Si 21 co 9 The XRD spectra and DSC curves of alloy powder samples are shown in figure 1 (c) and figure 2 (c). After the powder mixture was mechanically ground for 48 hours, typical diffuse peaks of amorphous characteristics and crystal diffraction peaks of Mo solid solution could be observed in the XRD spectrum; an obvious exothermic reaction caused by crystallization could be observed in the DSC curve of the ball-milled powder , these evidences indicate that mechanical milling forms the alloy as a mixture of crystalline and amorphous phases. The process and principle of performing peak-splitting fitting on the XRD spectrum to estimate the volume fraction of the amorphous phase in the ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com