Clarifying device and method for centrifugally clarifying giass

A clarification device and glass technology, which is applied in glass production, glass furnace equipment, glass manufacturing equipment, etc., can solve the problems of difficult to guarantee glass and molten glass, and achieve the effects of shortened residence time, reduced size, and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

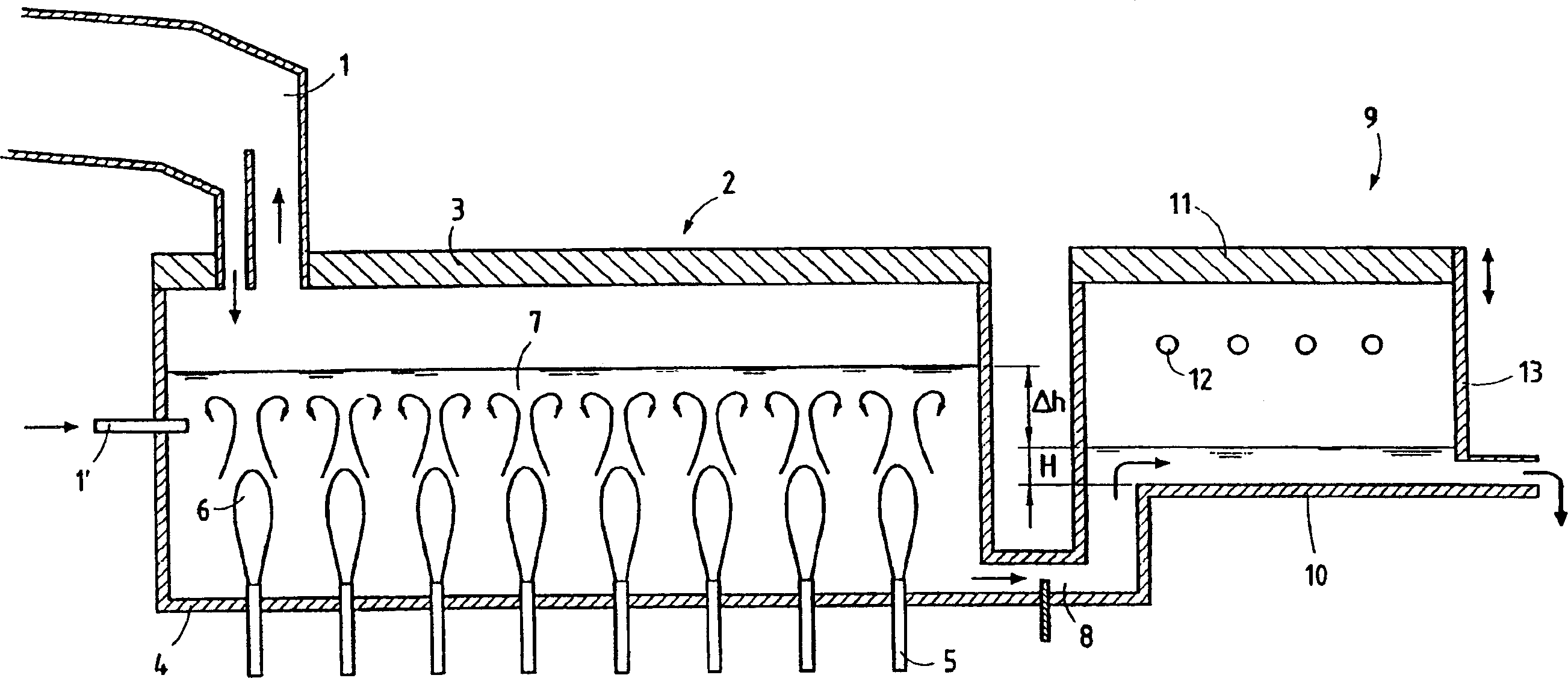

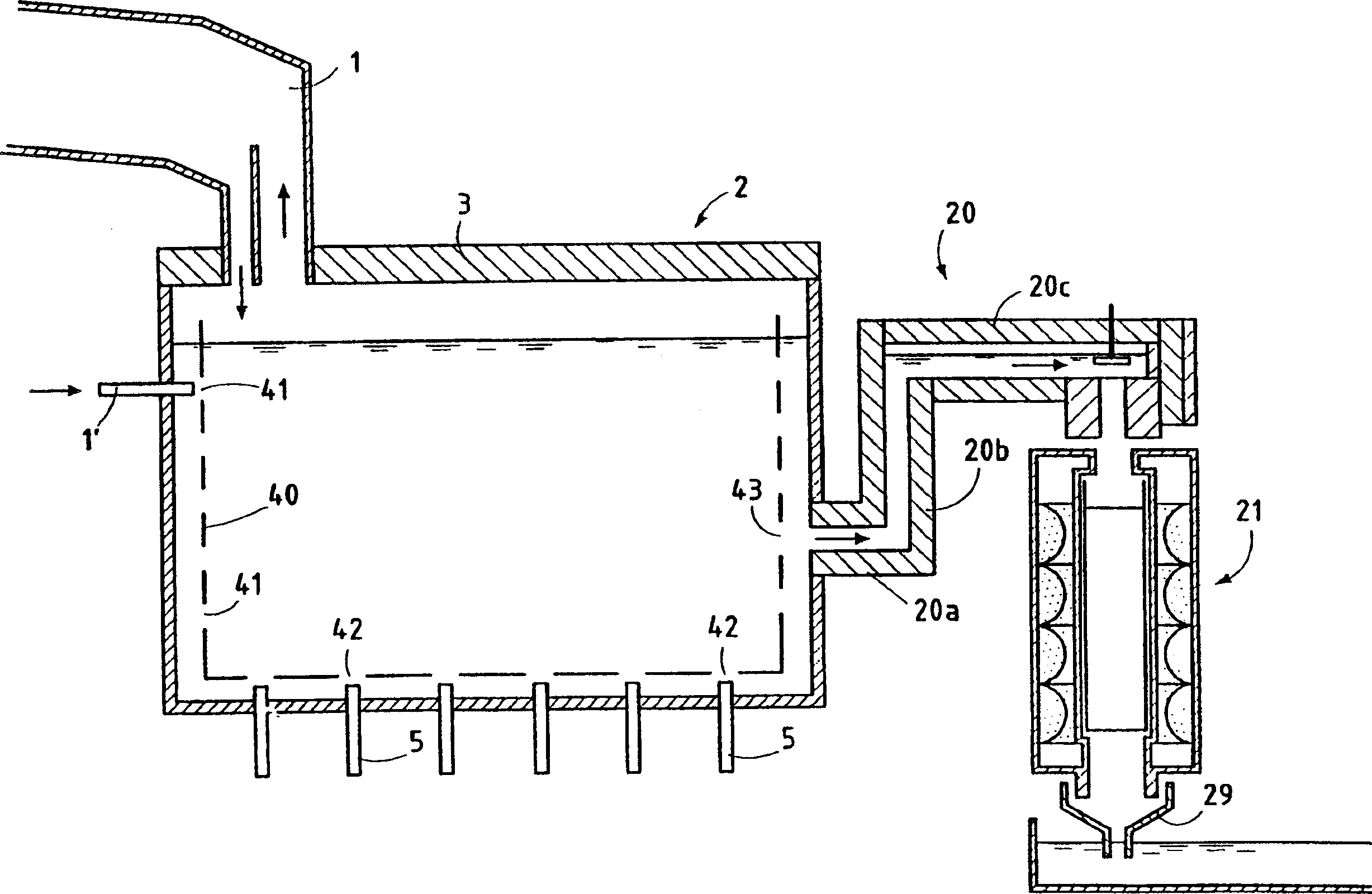

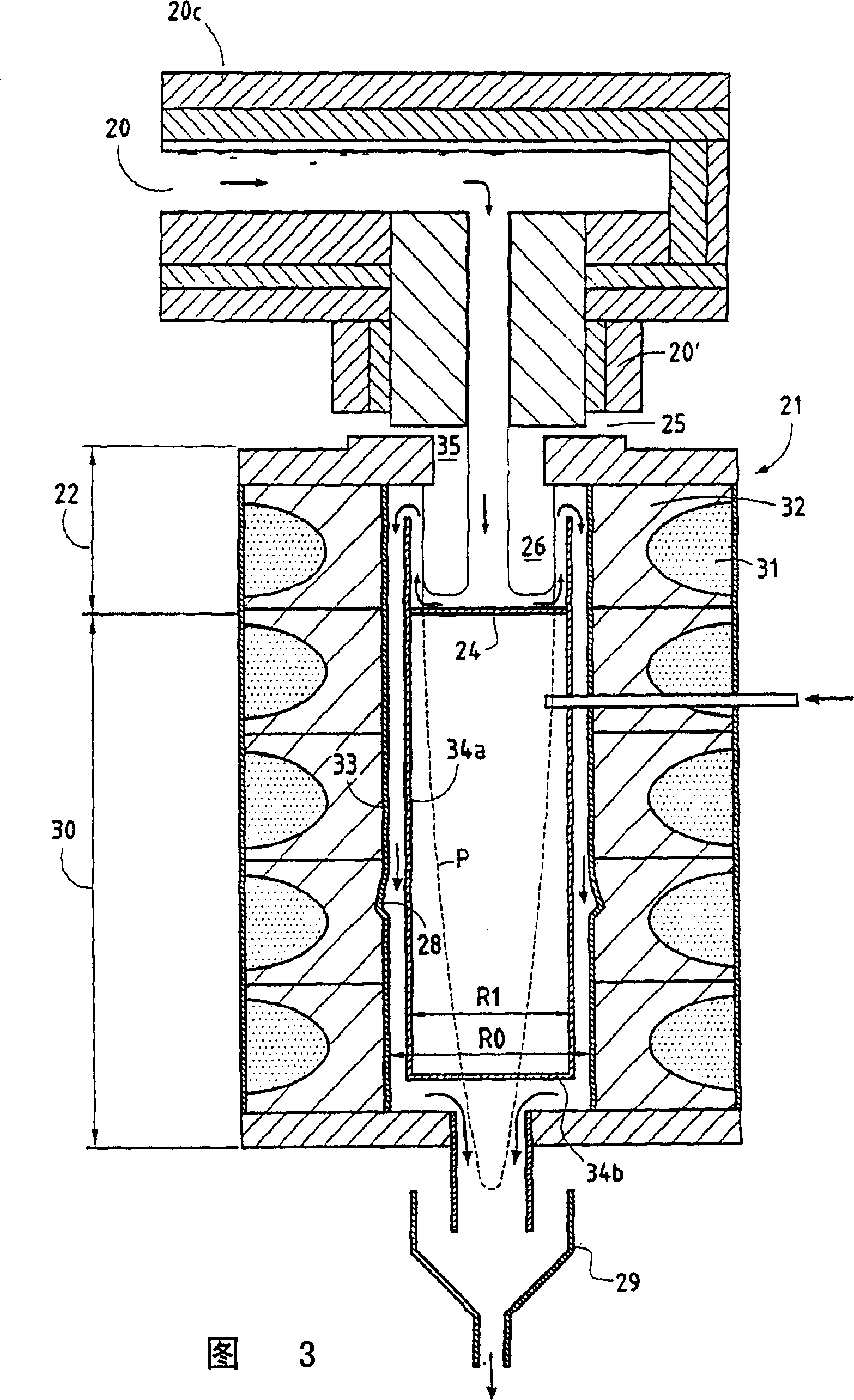

[0088] The device described below is suitable for melting and refining glasses with very different compositions, and the glass here is supplied to float glass production equipment for the production of flat glass. In particular, these glasses can also be supplied to hollow glass forming equipment or to fiber-forming equipment using centrifugal action devices.

[0089] Of course, in addition to any standard glass of silicon-sodium-calcium type, it is particularly advantageous to use the device of the present invention to produce different types of special glass, especially the glass that has been considered difficult to melt so far:

[0090] With low Na 2 Glass with O content and relatively high content of alkaline earth metal oxides (specifically CaO) is economically advantageous in terms of raw material cost, but it has great corrosion resistance at normal melting temperatures and adopts the usual methods. The melting is still quite hard. It may involve, for example, the glass c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com