Removal position-indicating adhesive tape

An adhesive tape, removal technology, applied in the direction of film/sheet-like adhesives, adhesives, adhesive products, etc., can solve the problem of failure to maintain shape, deterioration, cellulose film does not have heat resistance, chemical resistance character issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

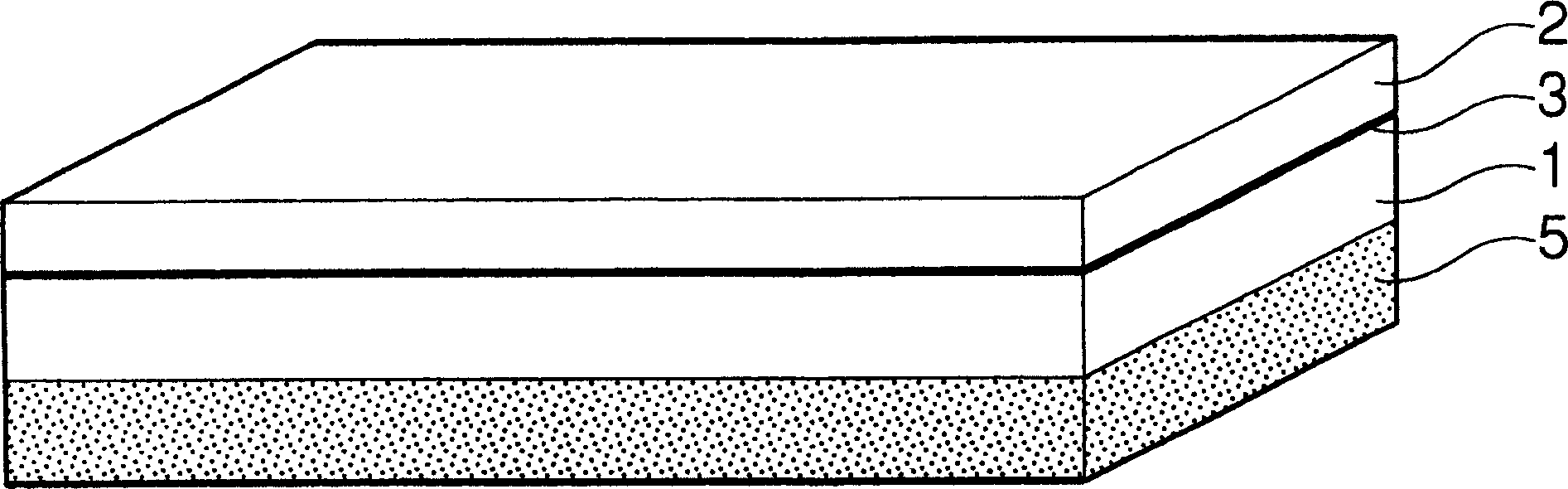

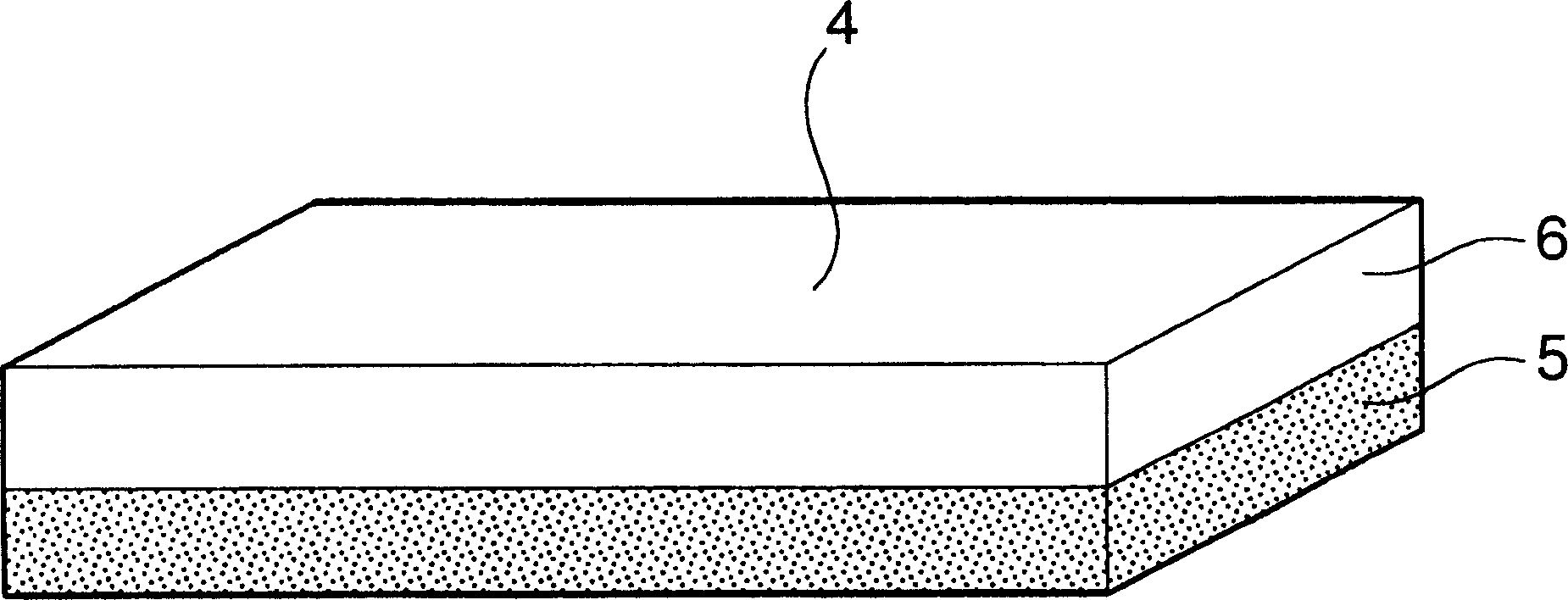

[0030] A film made of polypropylene resin with a thickness of 70 μm was cut to prepare a base layer having a length of about 5 cm and a width of 19 mm. A film made of polypropylene resin having a thickness of 50 μm was cut into the same size and shape as the base layer to prepare a protective film. Then, using acrylic ink, the figure or mark of the hook is printed on one side (surface) of the protective film, and the polyester adhesive is coated on the printed surface of the protective film, and the protective film is made by heat or pressure. The membrane is bonded to the base layer. Subsequently, an acrylic adhesive was coated on the side (or surface) of the base layer facing away from the protective film to form an adhesive layer, whereby a test piece was prepared.

[0031] The heat resistance and battery liquid resistance properties of the test pieces thus obtained were evaluated in the following manner.

[0032] [Heat resistance evaluation]

[0033]The test pieces were...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com