Surface acoustic wave element and manufacturing method thereof

A surface acoustic wave and manufacturing method technology, applied in the direction of electrical components, impedance networks, etc., can solve problems such as difficulty in uniform thickness, steep passage characteristics, and inability to obtain stable frequency characteristics, and achieve the effect of stable frequency characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

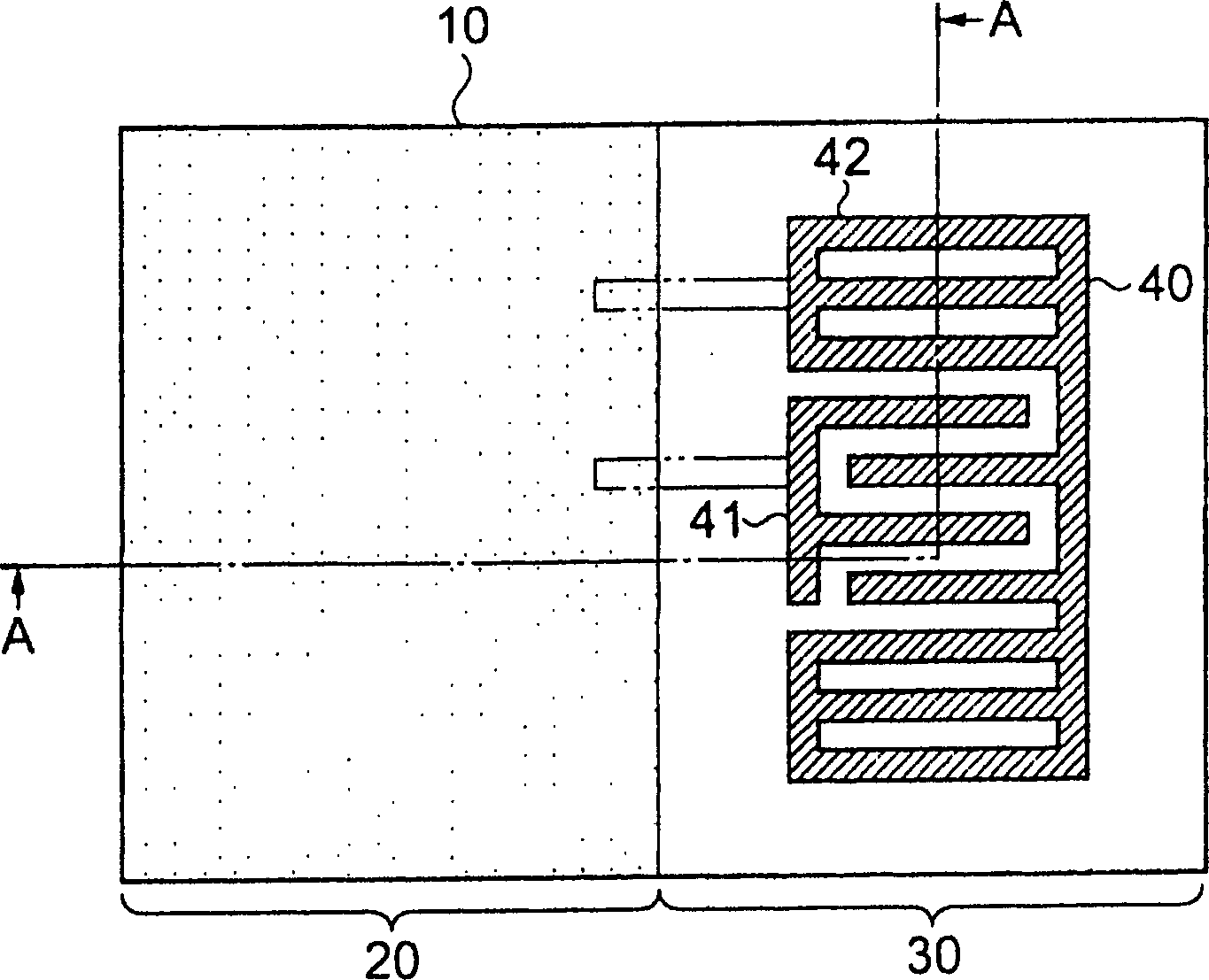

[0033] figure 1 It is a plan view showing the surface acoustic wave element of the first embodiment. exist figure 1In the surface acoustic wave element 10, the silicon layer 50 (refer to figure 2 ), the semiconductor wiring region 20 and the SAW region 30 are arranged side by side in the same plane. In the semiconductor wiring region 20, four layers of metal wiring (not shown) are formed (see figure 2 ). In addition, a comb-shaped IDT 40 is formed on the uppermost layer of the SAW region 30 .

[0034] The IDT 40 is composed of A1, has an input-side electrode 41 and an output-side electrode 42 inserted into each other, has terminals for input or output, respectively, and these terminals are connected to predetermined metal wirings not shown in the semiconductor region.

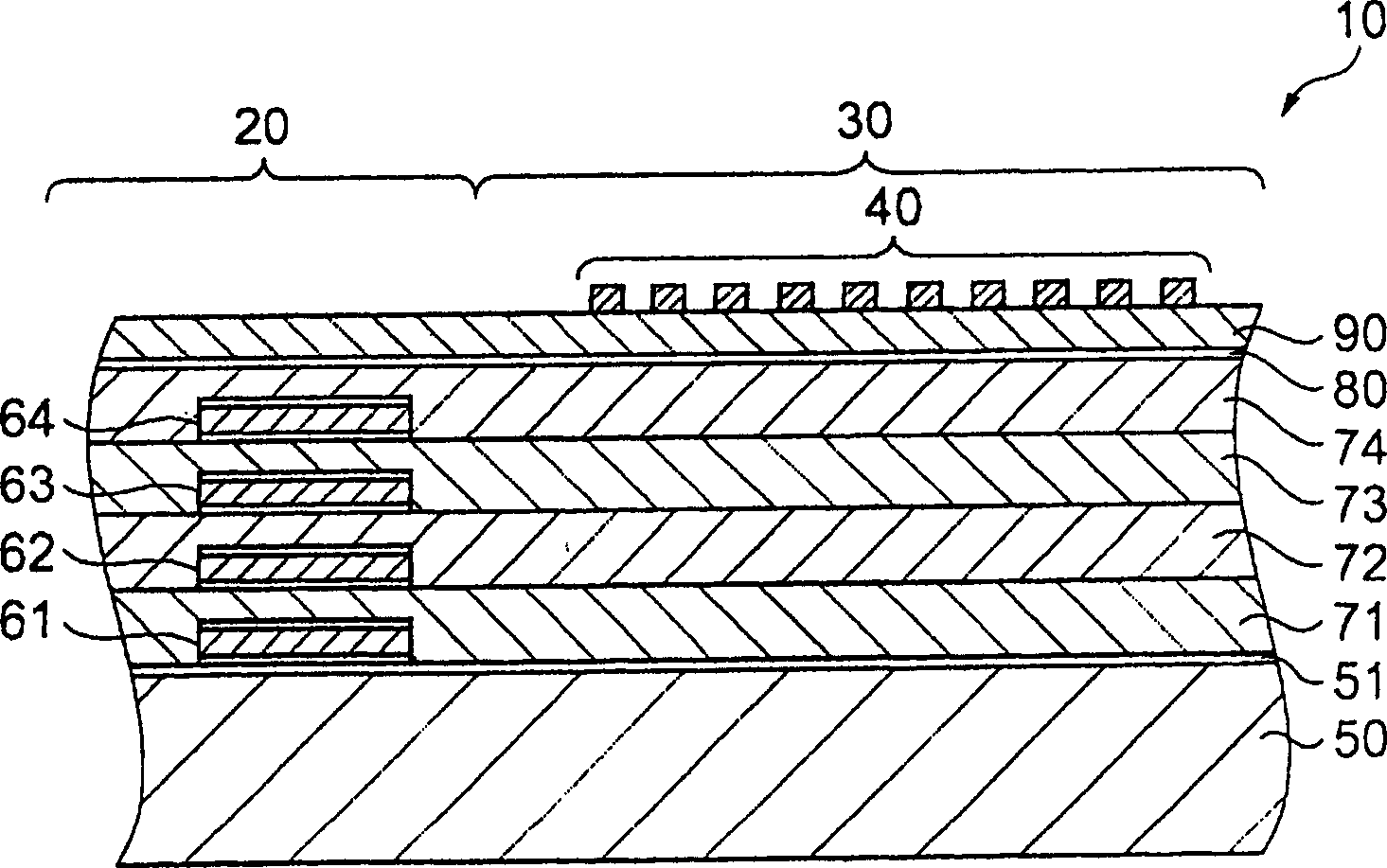

[0035] exist figure 2 shows the surface acoustic wave device 10 of this embodiment figure 1 Use the partial cross-sectional view shown in A-A. exist figure 2 In the surface acoustic wave device 10,...

Embodiment approach 2

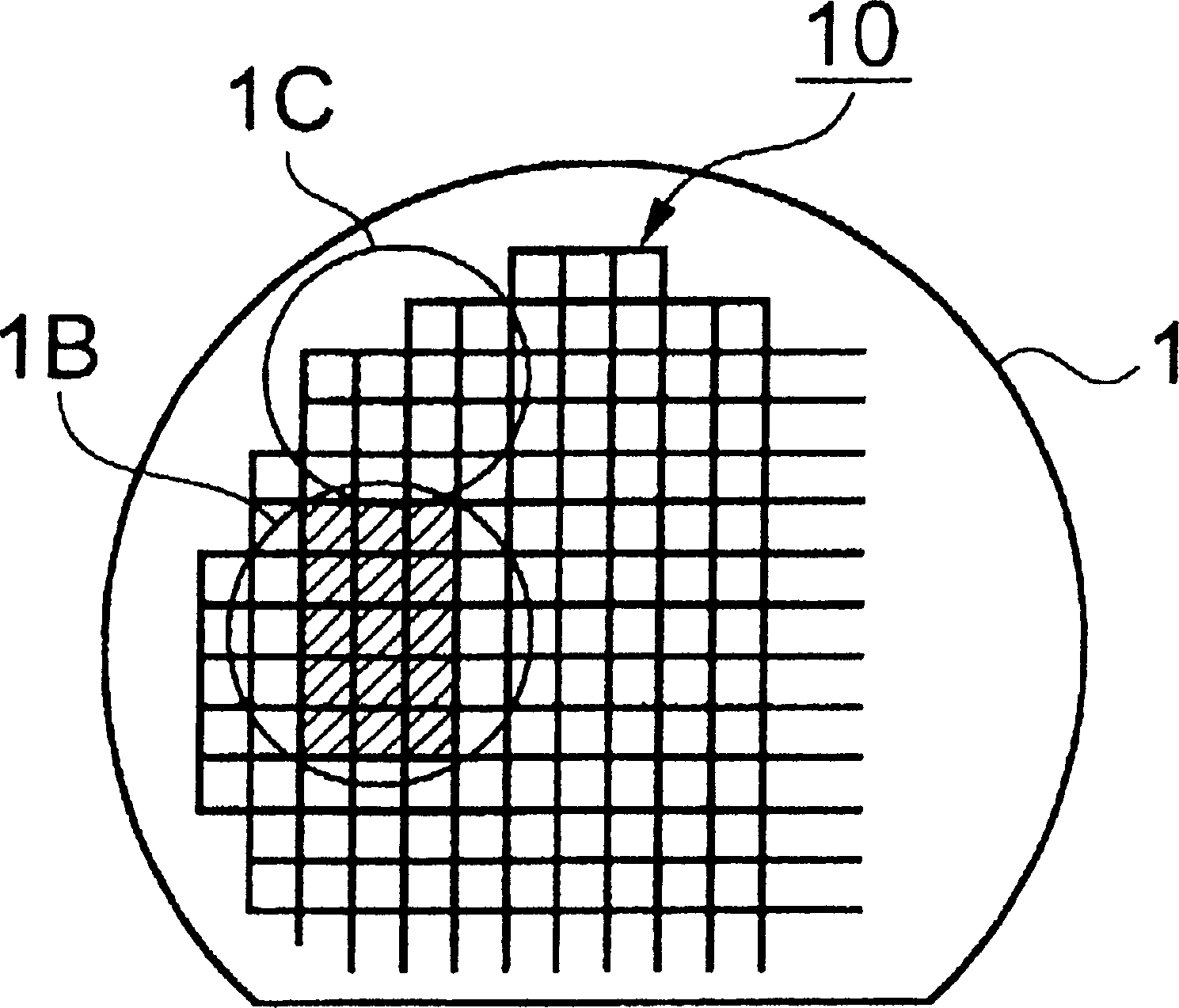

[0068] Next, a surface acoustic wave device according to Embodiment 2 of the present invention will be described with reference to the drawings. Embodiment 2 is based on the technical idea of Embodiment 1 described above, and particularly aims at improving the uniformity of the thickness of the insulating layer in the SAW region of the surface acoustic wave element formed on the outer peripheral portion of the wafer.

[0069] exist Figure 9 shows the surface acoustic wave device of Embodiment 2, Figure 9 (a) is a partial plan view showing the arrangement of the surface acoustic wave element 10 in the wafer 1, enlarged and schematically shown image 3 1C region shown. exist Figure 9 (b) shows along the Figure 9 (a) The cross-sectional view of the B-B line shown in Figure 9 (c) shows a cross-sectional view along line C-C. exist Figure 9 (a)~ Figure 9 In (c), the metal wiring layer 21 is formed on the outer peripheral portion of the surface acoustic wave element ...

Embodiment approach 3

[0074] Next, Embodiment 3 of the present invention will be described with reference to the drawings. Embodiment 3 is characterized in that Embodiment 1 (refer to figure 2 ) shows that the formation range of the piezoelectric layer 90 is limited to the SAW region, and other structures are the same as those in Embodiment 1, so descriptions are omitted and the same reference numerals are used.

[0075] exist Figure 10 A cross section of the surface acoustic wave element 10 according to Embodiment 3 is shown in . exist Figure 10 In this example, a protective layer 80 is formed within the range of the SAW region 30 on the uppermost insulating layer 74 , and a piezoelectric layer 90 is formed thereon, and an IDT is formed on the piezoelectric layer 90 .

[0076] According to the structure of the third embodiment, the structures and manufacturing methods of the aluminum wirings 61 to 64 and the insulating layers 71 to 74 are the same as those of the first embodiment, and the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com