Preparation method of multilayer BST (Barium Strontium Titanate) film based on gradient pre-crystallization heat treatment

A thin film preparation and pre-crystallization technology, which is applied in the preparation of barium strontium titanate (BST) thin film and multi-layer BST thin film, can solve the problems of complex process, low tuning rate, and many process parameters, and achieve simplified process , stable frequency characteristics, small grain gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

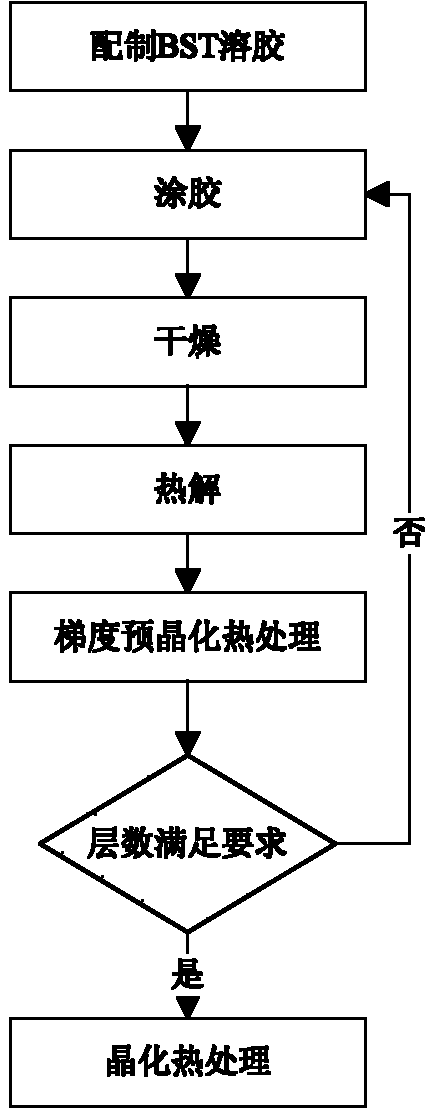

Method used

Image

Examples

Embodiment 1

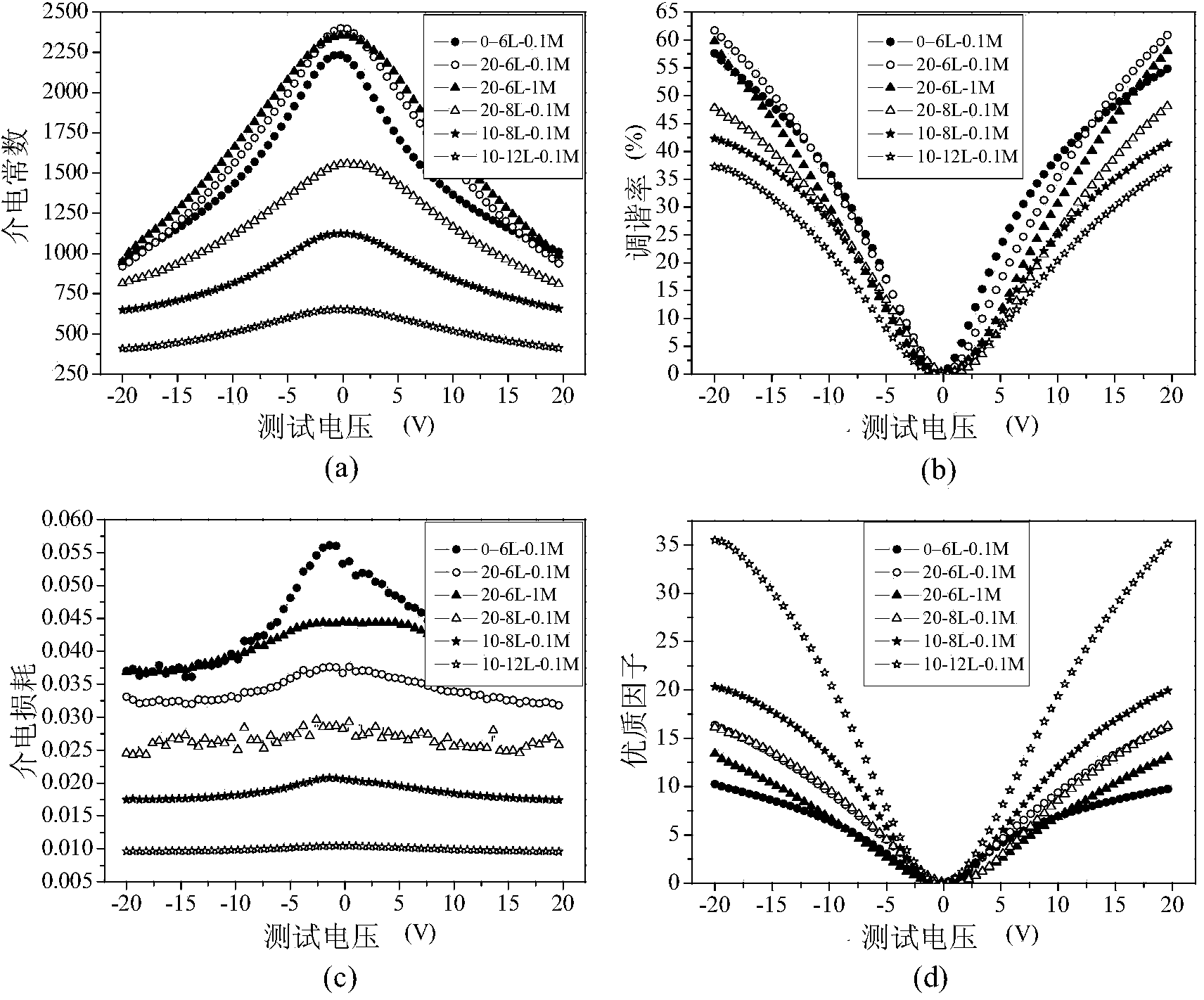

[0040] Example 1 of the present invention: Gradient pre-crystallization heat treatment with ΔT=20°C and Δt=0 for 6 layers of pure Ba 0.6 Sr 0.4 TiO 3 Film Preparation

[0041] The implementation steps are as follows:

[0042] It is basically the same as the "steps of Example 2", except that the pre-crystallization heat treatment temperatures of the first to sixth layers in step (1) are 550°C, 570°C, 590°C, 610°C, 630°C, 650°C, respectively .

Embodiment 4

[0043] Example 4: Gradient pre-crystallization heat treatment with ΔT=20°C and Δt=0 for 8 layers of pure Ba 0.6 Sr 0.4 TiO 3 Film Preparation

[0044] The implementation steps are as follows:

[0045] It is basically the same as the "steps of Example 2", except that the pre-crystallization heat treatment temperatures of the first to eighth layers in step (1) are 550°C, 570°C, 590°C, 610°C, 630°C, and 650°C, respectively. , 670°C and 690°C, and the crystallization temperature in step (4) was 690°C.

Embodiment 5

[0046] Example 5: Gradient pre-crystallization heat treatment with ΔT=10°C and Δt=0 for 8 layers of pure Ba 0.6 Sr 0.4 TiO 3 Film Preparation

[0047] The implementation steps are as follows:

[0048] It is basically the same as "Steps of Example 2", except that the pre-crystallization heat treatment temperatures of the first layer to the eighth layer in step (1) are 550°C, 560°C, 570°C, 580°C, 590°C, and 600°C, respectively. , 610°C and 620°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com