Piezoelectric resonator, etching amount detecting device, and oscillator

A piezoelectric vibrator and auxiliary vibration technology, which is applied in power oscillators, frequency measuring devices, electrical components, etc., can solve problems such as the inability to move the auxiliary vibration oscillation frequency, achieve stable frequency characteristics, and reduce adverse effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

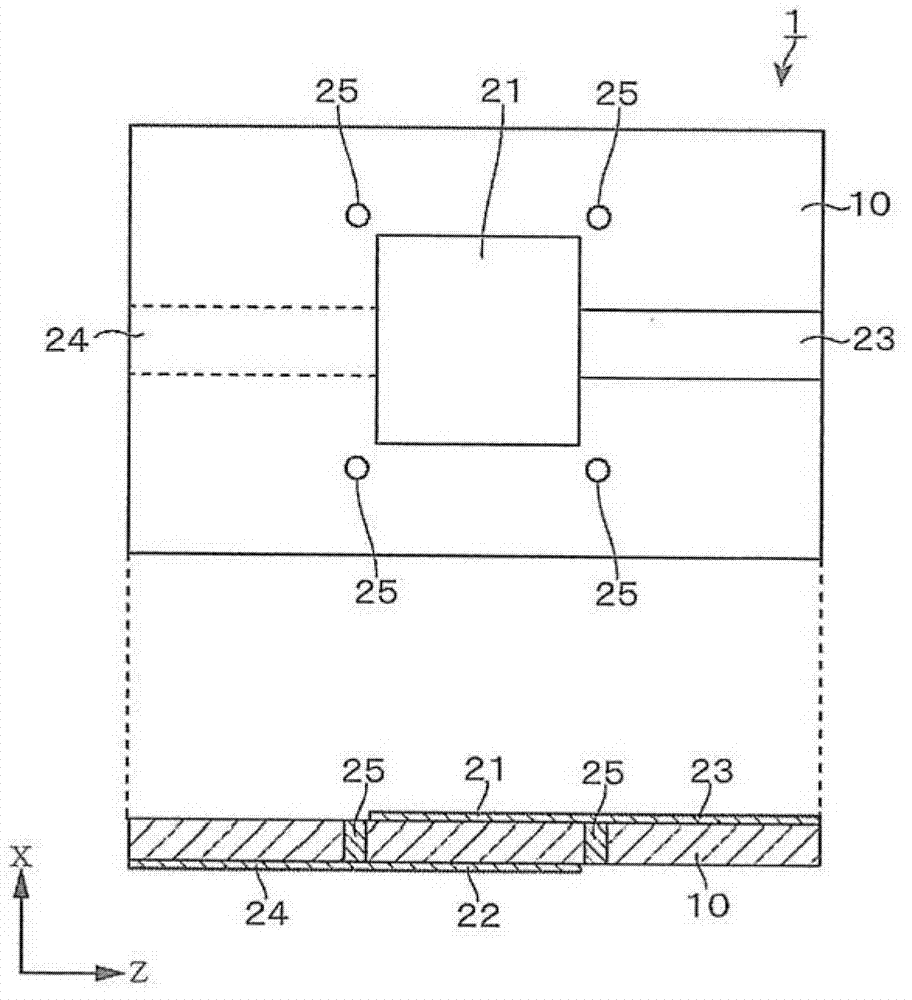

[0089] Hereinafter, an embodiment of a crystal oscillator forming the piezoelectric vibrator of the present invention will be described. Such as figure 1 As shown, this crystal oscillator 1 is configured by providing excitation electrodes 21 and 22 on both surfaces of a piezoelectric crystal plate 10 , respectively. The crystal plate 10 is, for example, an AT-cut crystal plate in the fundamental mode, and is configured to oscillate at 38.4 MHz with thickness-shear vibration as the main vibration. As an example of this embodiment, the planar shape of the crystal plate 10 is, for example, a rectangle such as a rectangle, and its dimensions are set to 1.0 mm in length×0.8 mm in width, and its thickness is set to 43.2 μm.

[0090] In order to excite the crystal plate 10 , excitation electrodes 21 and 22 are formed at the center of both surfaces of the crystal plate 10 so as to face each other. These excitation electrodes 21 and 22 are, for example, square, and one side is approp...

no. 2 approach

[0117] Below, use Figure 5 , another embodiment of the crystal oscillator forming the piezoelectric vibrator of the present invention will be described. If take the Figure 5 The illustrated crystal oscillator 1a is taken as an example to describe the crystal oscillator 1a of this embodiment, and the crystal plate 10 used for the crystal oscillator 1a is, for example, an AT-cut fundamental wave mode crystal plate, and is configured as a main vibration. Thickness shear vibration oscillates at 38.4 MHz. As an example of this embodiment, the planar shape of the crystal plate 10 is, for example, a rectangle such as a rectangle, the dimensions are set to 1.0 mm in length x 1.6 mm in width, and the thickness is set to 43.2 μm.

[0118] In the present embodiment, the axis of a part of the crystal plate 10 in the shape of a belt is reversed to make it twin-crystallized. In this crystal oscillator 1 a , the strip-shaped portion whose axis is inverted is called an axis-inverted port...

Embodiment

[0150] As an example, temperature characteristics of the oscillation frequency were measured for the crystal oscillator of the first embodiment. As a comparative example, for Figure 13 The crystal oscillator of the first embodiment shown in which the secondary vibration suppressing unit 25 is removed, that is, the conventional crystal oscillator was used to measure the temperature characteristics of the oscillation frequency, and this was used as a comparative example.

[0151] The crystal oscillator used for the measurement oscillates in the AT-cut fundamental wave mode, and the oscillation frequency of the main vibration is f 0 = 38.4MHz crystal chip. Regarding the crystal oscillator of the embodiment and the crystal oscillator of the comparative example, in Figure 11 The crystal oscillation circuit shown is used as crystal oscillator 1, the oscillation frequency is measured, and the f 0 The temperature characteristics of the error Δf. Figure 11 Among them, C1~C4 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com