Method and device for removing magnetic foreign objects from liquid

A magnetic and foreign matter technology, which is applied in separation methods, chemical instruments and methods, magnetic separation, etc., can solve the problem of cleaning liquid magnetic foreign matter scraping off, etc., and achieve the effects of shortening the discharge time, improving the removal efficiency, and prolonging the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

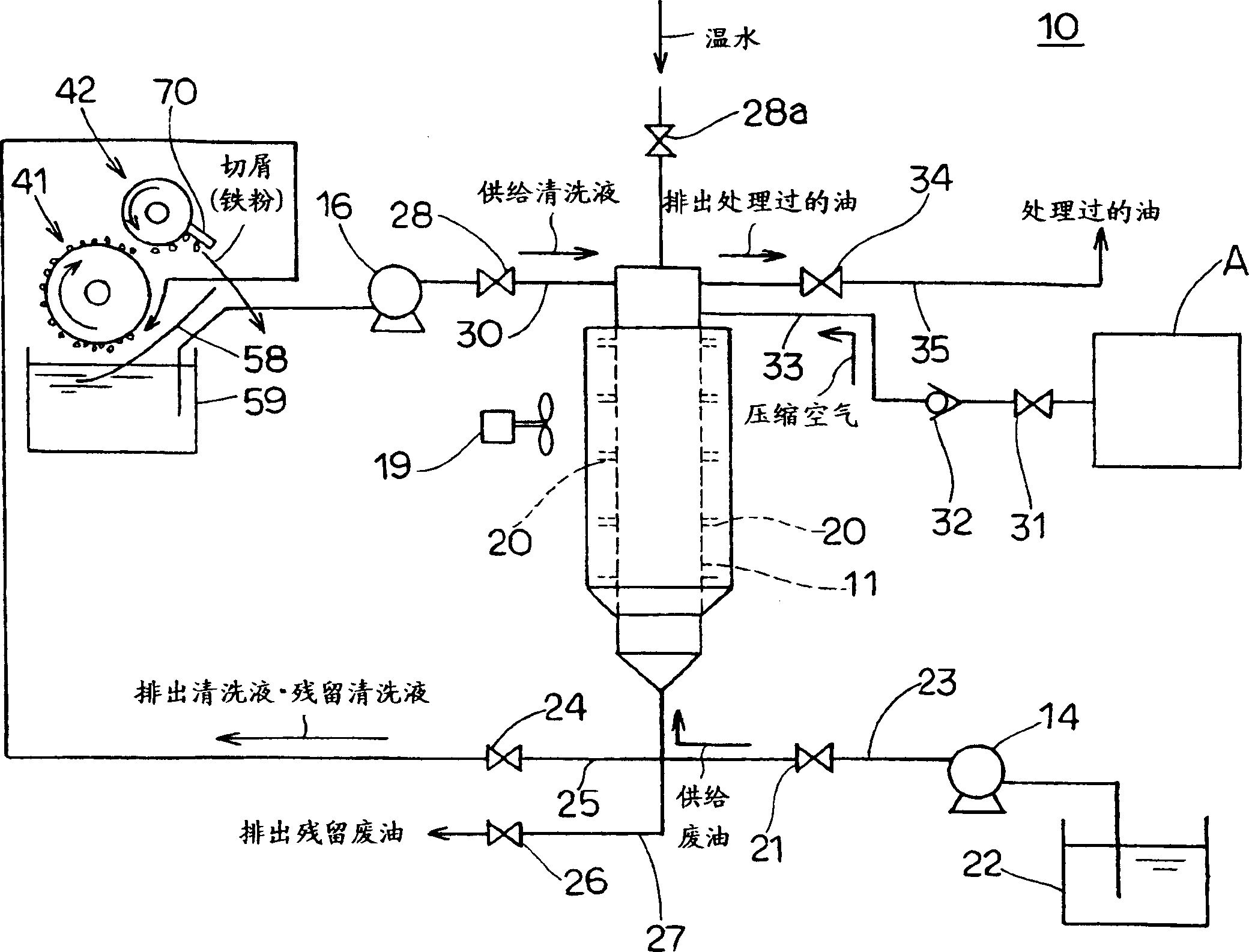

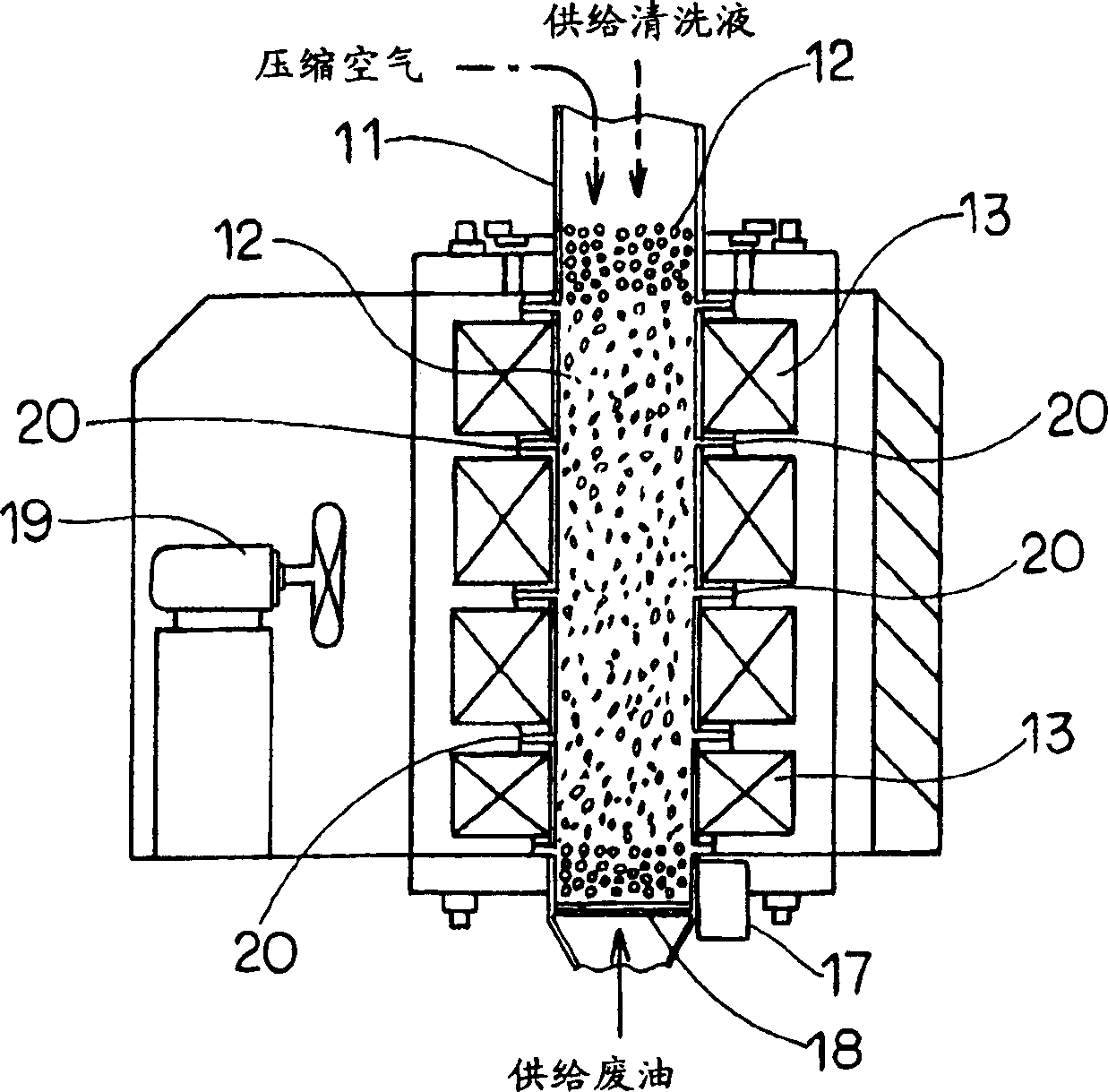

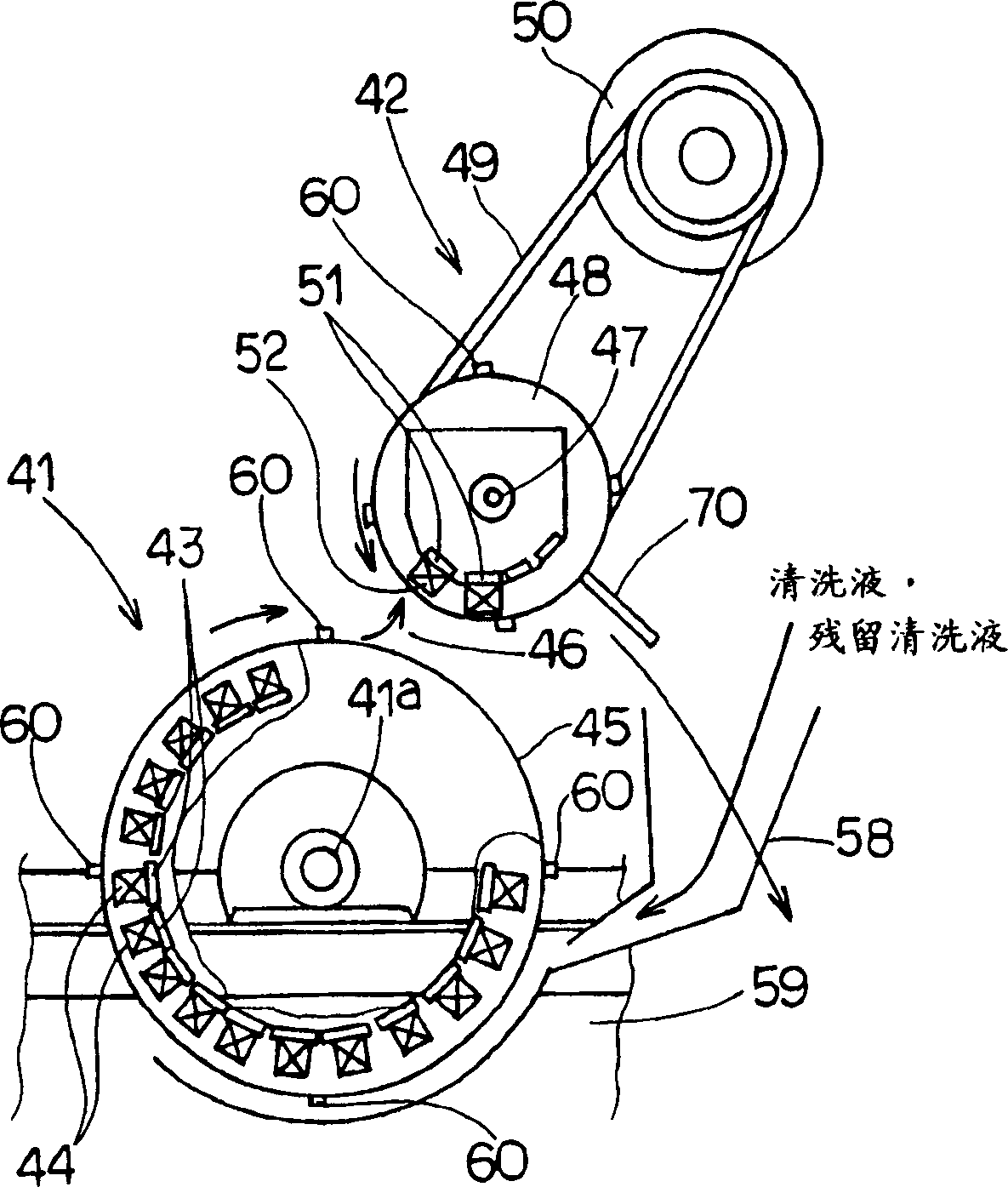

[0090] exist figure 1 as well as figure 2 Among them, the reference numeral 10 refers to the device for removing magnetic foreign matter from the liquid (hereinafter referred to as the removing device) according to Embodiment 1 of the present invention. , a lower opening is formed at the lower end, which is made of stainless steel and has a cylindrical shape; a plurality of magnetic spheres (magnetic bodies) 12 made of steel are accommodated in the inside of the cylinder 11; excitation coils 13 are arranged on The outer periphery of the cylinder 11 excites the magnetic ball 12 inside the cylinder 11; the pump (liquid supply mechanism) 14 supplies the waste oil (liquid) mixed with cuttings (magnetic foreign matter) from the lower opening. To the inside of the cylinder 11; the treated oil discharge pipe 35, which discharges the treated oil from the cylinder 11; the waste oil discharge pipe (liquid discharge mechanism) 27, which discharges the waste oil containing chips in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com