Method for treatment of arsenic-contaminated soil

一种砷污染、土壤的技术,应用在处理砷污染土壤领域,能够解决经济不利等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

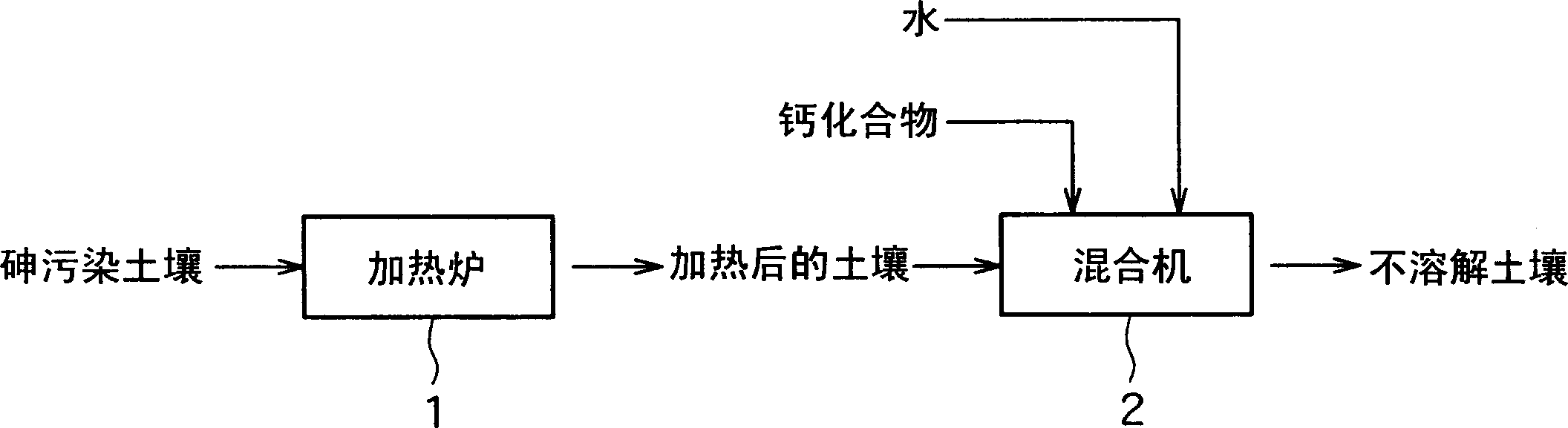

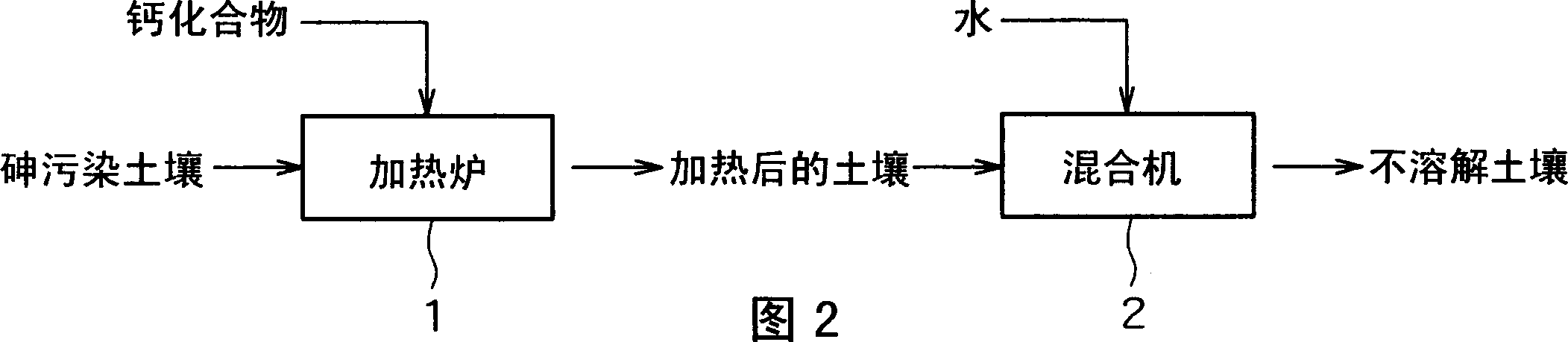

Method used

Image

Examples

Embodiment 1

[0047] The following four experiment numbers 1 to 4 were carried out as comparative examples. A sample of arsenic-contaminated soil (Kanto loam) containing 0.097 mg / L of leachable arsenic was obtained. The samples (100 pbw) were thoroughly mixed with water and varying amounts of slaked or quicklime as follows.

[0048] In number 1, 40pbw of water and 5pbw of slaked lime.

[0049] In number 2, 40pbw of water and 7pbw of slaked lime.

[0050] In number 3, 40pbw of water and 12pbw of slaked lime.

[0051] In No. 4, 40pbw of water and 5pbw of quicklime.

[0052] The mixture was allowed to stand at room temperature.

[0053] After aging for 1 day, 7 days and 28 days, the arsenic leaching of the mixture was measured according to the method specified in the Environmental Quality Standard for Solid Pollutants (Circular No. 46) by the Ministry of Environment Agency of Japan. The test results are shown in Table 3.

[0054] experiment

[0055] In Example 1, the following ...

Embodiment 2

[0065] The following two experiments, numbered 9 and 10, were carried out in Example 2. A sample of arsenic-contaminated soil (Kanto loam) having a leached arsenic amount of 0.109 mg / L was obtained from the same place as in the comparative example. Its arsenic content is about 4 times of the arsenic content in Example 1. The samples were heated in a furnace at 550°C for 20 minutes under an air atmosphere. The heated samples (100pbw) were thoroughly mixed with water below and varying amounts of quicklime.

[0066] In No. 9, 40pbw of water and 3pbw of quicklime.

[0067] In No. 10, 40pbw of water and 5pbw of quicklime.

[0068] The mixture was allowed to stand at room temperature.

[0069] After aging for 1 day, 7 days and 28 days, the arsenic leaching of the mixture was measured according to the method specified by the Japanese Ministry of the Environment in Circular No. 46. The test results are shown in Table 5.

[0070] Reality

[0071] Can know from table 5,...

Embodiment 3

[0073] Example 3 The following three experiments were carried out, numbered 11-13. A sample of arsenic-contaminated soil (Kanto loam) was obtained from the same place as in the comparative example, and the amount of leachable arsenic contained in the sample was about 3 to 4 times that of Example 2. The sample (100 pbw) was mixed with quicklime (3 pbw in code 11, 5 pbw in code 12, 10 pbw in code 13). The mixture was heated in a furnace at 550°C for 20 minutes under an air atmosphere. The heated mixture (100 pbw) was mixed thoroughly with water (40 pbw). The mixture was allowed to stand at room temperature. After aging for 1 day, 7 days and 28 days, the arsenic leaching of the mixture was measured according to the method specified by the Japanese Ministry of the Environment in Circular No. 46. The test results are shown in Table 6.

[0074] Reality

[0075] Can know from table 6, as shown in experiment number 11~13 among the embodiment 3, the combination of heat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com