Alignment system, vertical tray transporting assembly, and deposition apparatus with the same

A technology of correction system and transfer device, which is applied in the field of correction system, vertical disk transfer device and evaporation device with this device, which can solve the problem of difficulty in applying large-area substrates, inability to obtain film thickness, and difficulty in evaporating precise patterns. and other issues to achieve the effect of minimizing the impact, ensuring the correction position, and correct correction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Hereinafter, the calibration system provided by the present invention will be described in detail with reference to the accompanying drawings.

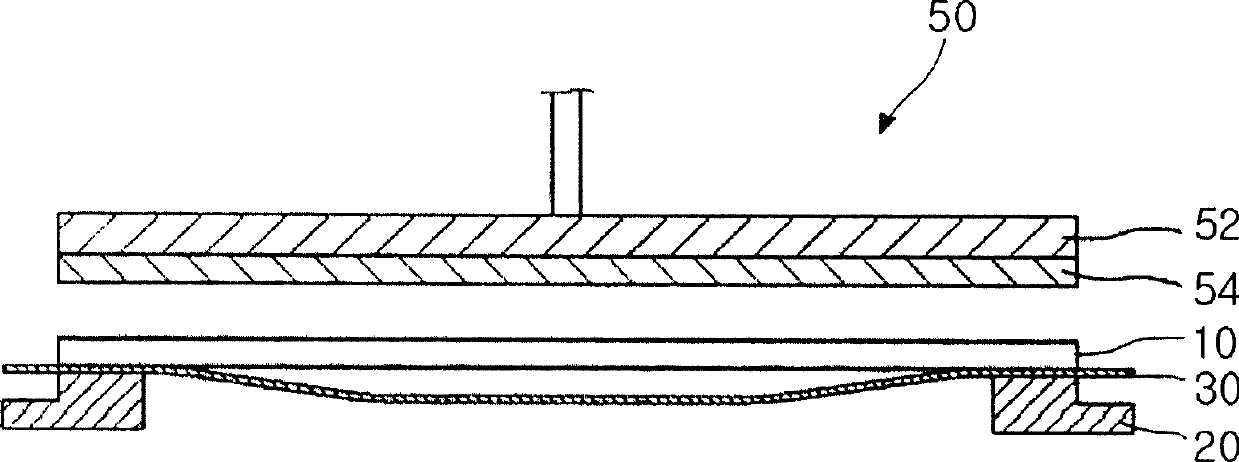

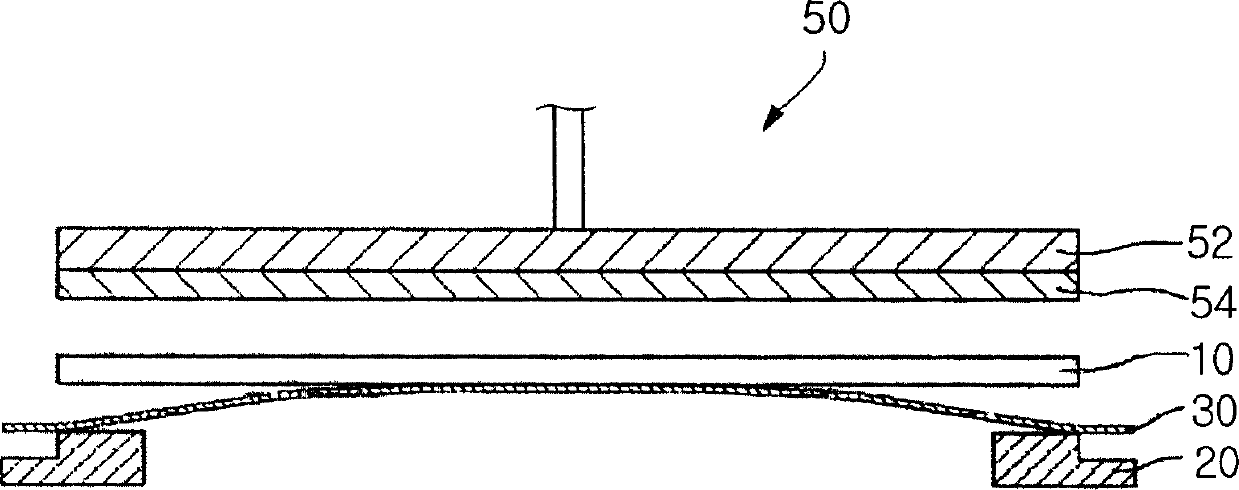

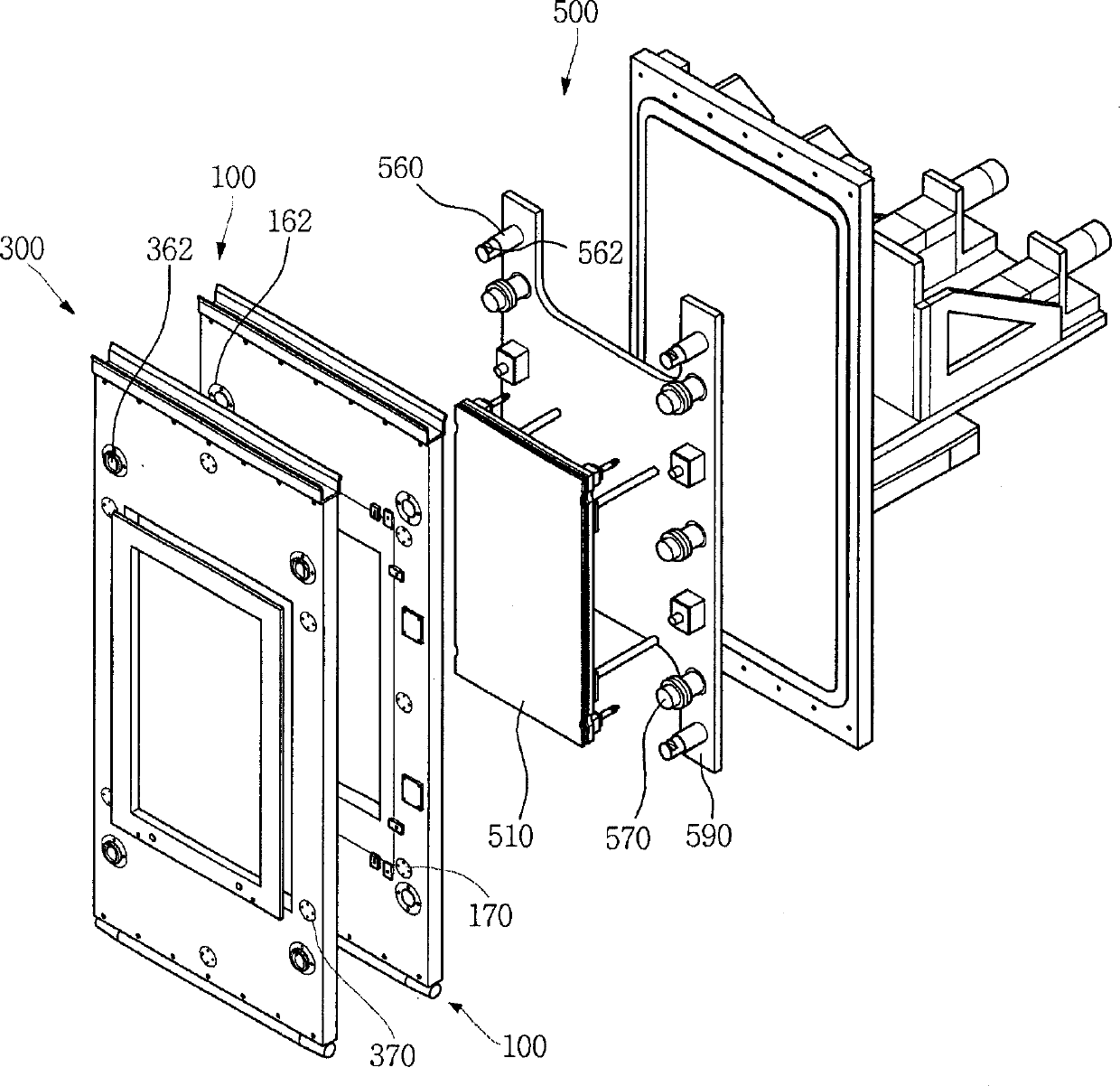

[0079] figure 2 To represent a schematic diagram of the correction system provided according to the preferred embodiment of the present invention, image 3 and Figure 4 to represent figure 2 Parts of the correction system shown are separate and combined side views, Figure 5a and Figure 5b to represent figure 2 The shown coupling part is pulled out and enlarged schematic diagram and the rear view of the coupling hole.

[0080] According to the correction system provided by the present invention such as figure 2 As shown, the mask (mask) disk 300 and the substrate disk 100 are simultaneously fixed to the disk holder 500 by the coupling portion while the distance between the substrate disk 100 and the support plate 590 of the disk holder 500 is controlled by zoom out. And, the alignment system maintains the fixed po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com