Autocontrolling multiline rotating, point cutter for diamond

A diamond wire and cutting machine technology, applied in the direction of stone processing tools, stone processing equipment, fine working devices, etc., can solve the problems of low efficiency, unsuitable for production fields, single wire cutting machine is not suitable for batch processing materials, etc., to achieve flexibility Design, improve cutting efficiency, convenient replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

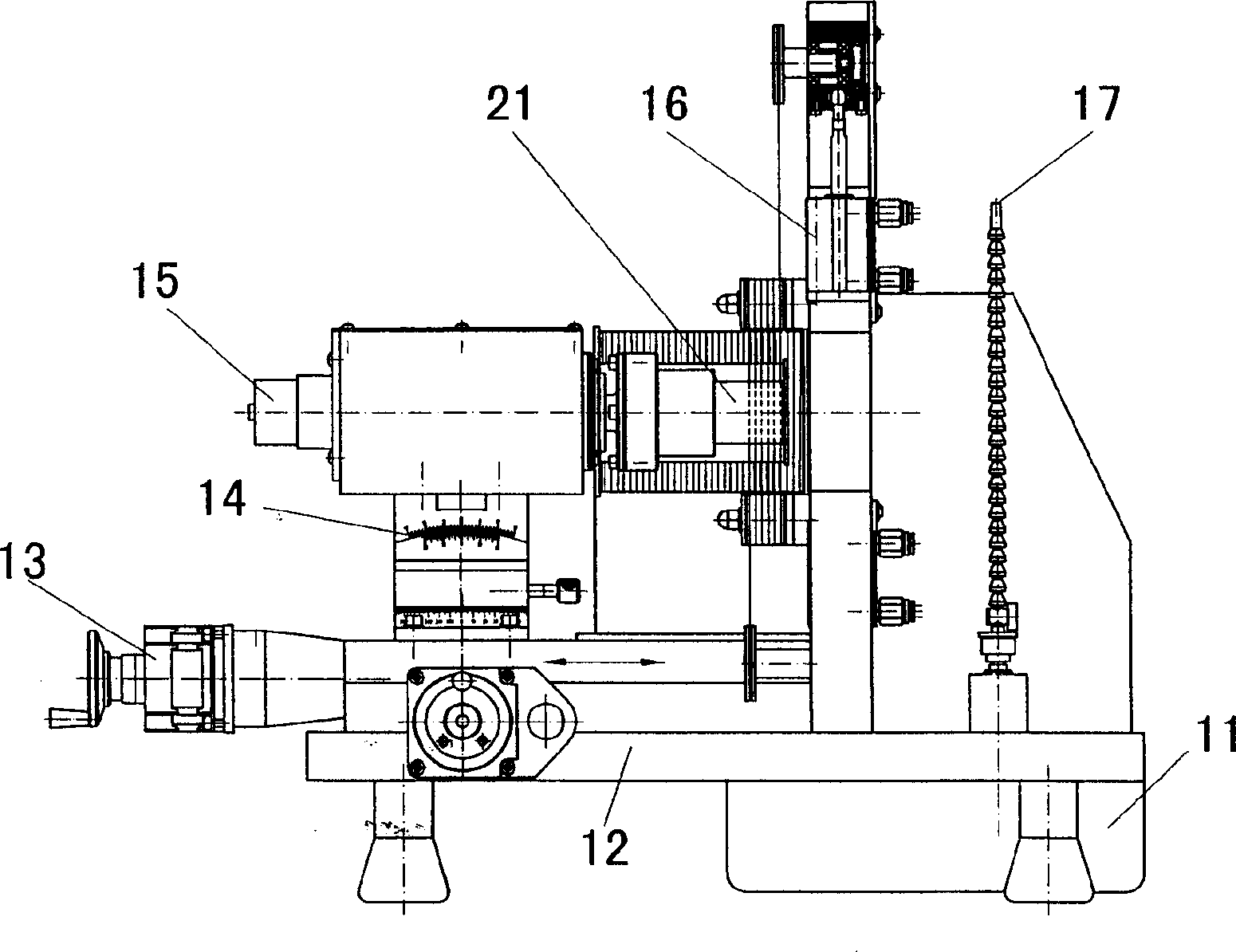

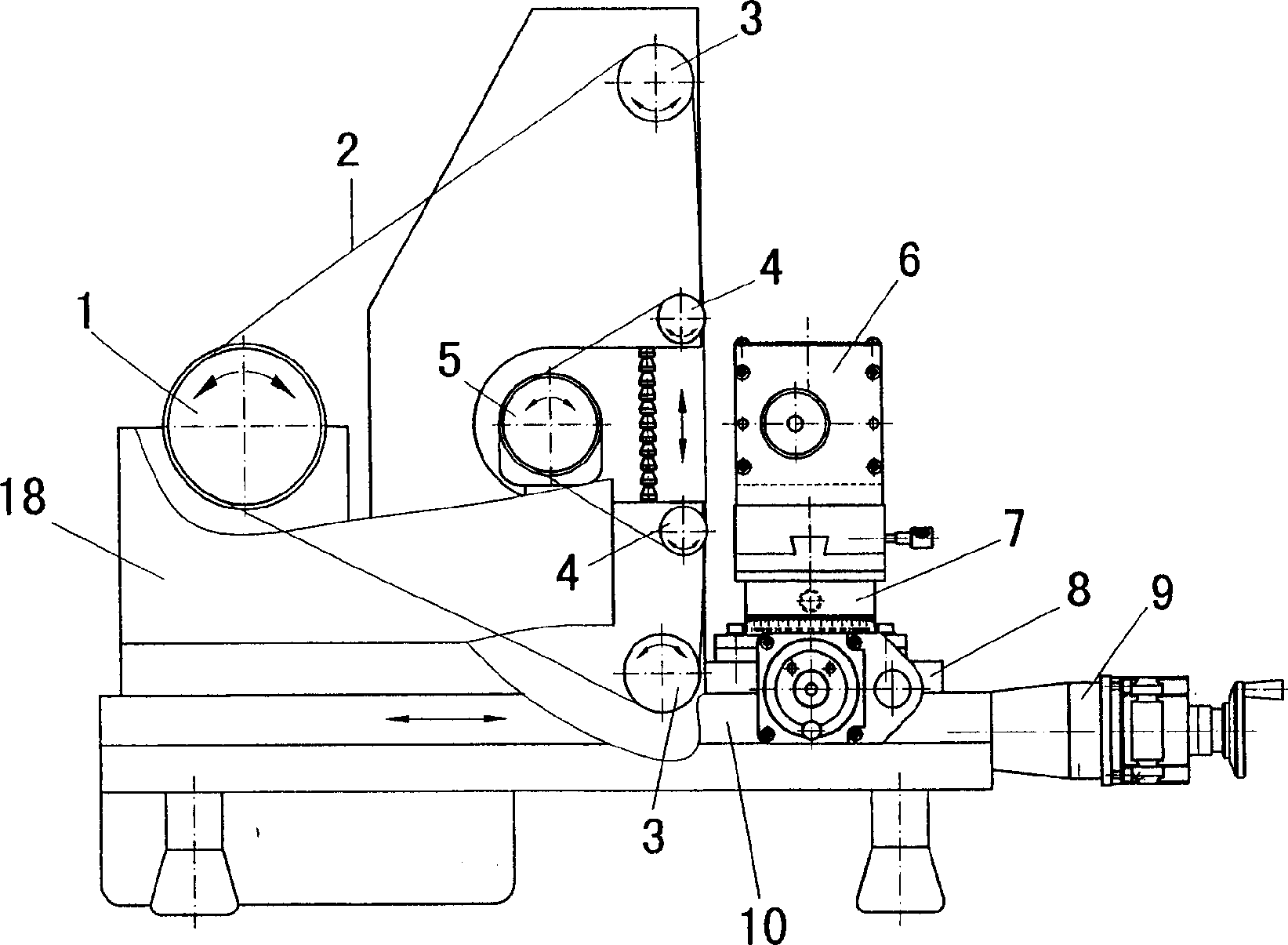

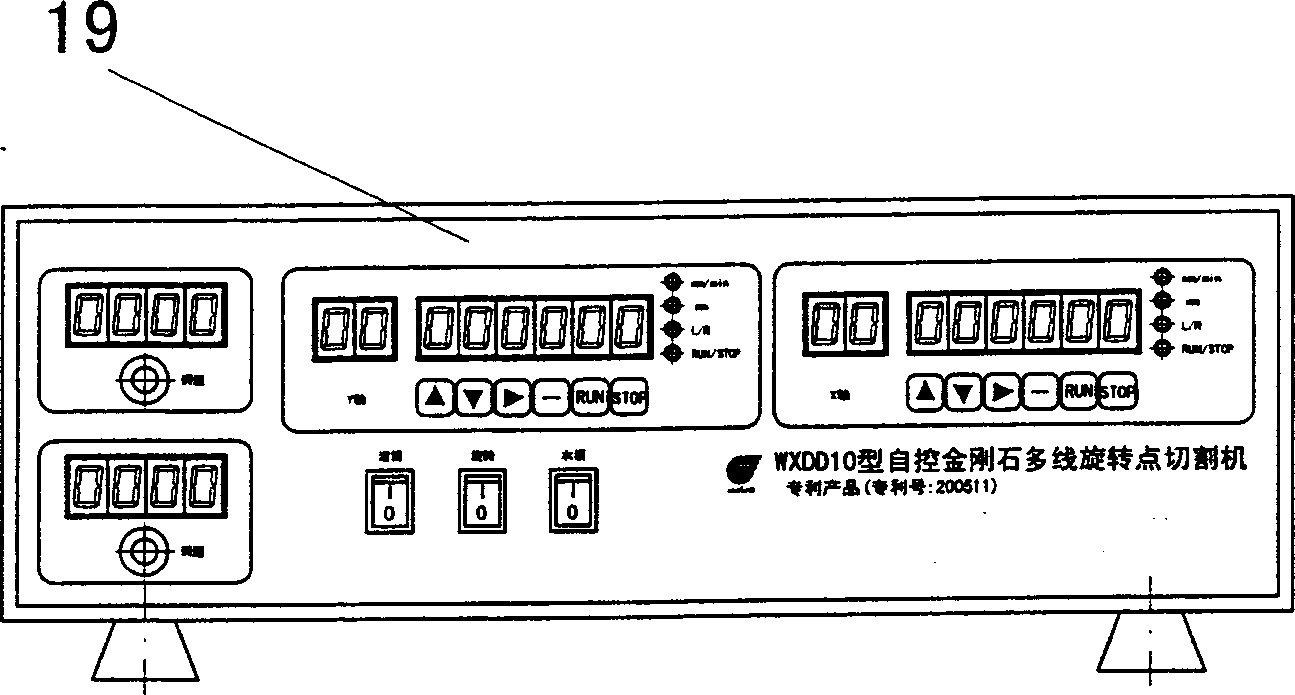

[0022] The self-controlled diamond multi-wire rotary point cutting machine is mainly composed of a reciprocating winding assembly: including a large drum (1), a small drum (5), a pneumatic tension wheel (3), a positioning wheel (4), and a diamond saw wire (2) ), rotary fixture assembly (6), horizontal angle adjustment turntable (7), Y-axis workbench (8), X-axis workbench stepper motor (9), X-axis workbench (10), and miniature submersible electric Pump water tank (11), machine base (12), Y-axis table stepper motor (13), vertical angle adjustment turntable (14), rotary fixture drive motor (15), diamond wire tensioning cylinder (16), cooling Water pipe (17), drum reciprocating mechanism (18), electric control box (19), air control box (20), comprise to be cut material (21) etc. to form.

[0023] Structure and composition:

[0024] 1. The base, bracket and water box are processed by cast aluminum to form the installation foundation;

[0025] 2. The reciprocating winding wire ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com