Aluminium transferring cigarette packing paper with laser punching and preparation method thereof

A technology of laser drilling and tipping paper, which is applied to laser welding equipment, wrapping paper, wrapping paper, etc., can solve the problems of poor air permeability and achieve the effect of restoring air permeability and reducing suction resistance

Inactive Publication Date: 2006-06-28

DARE TECH

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the tipping papers of the above technologies all have the disadvantage of poor air permeability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

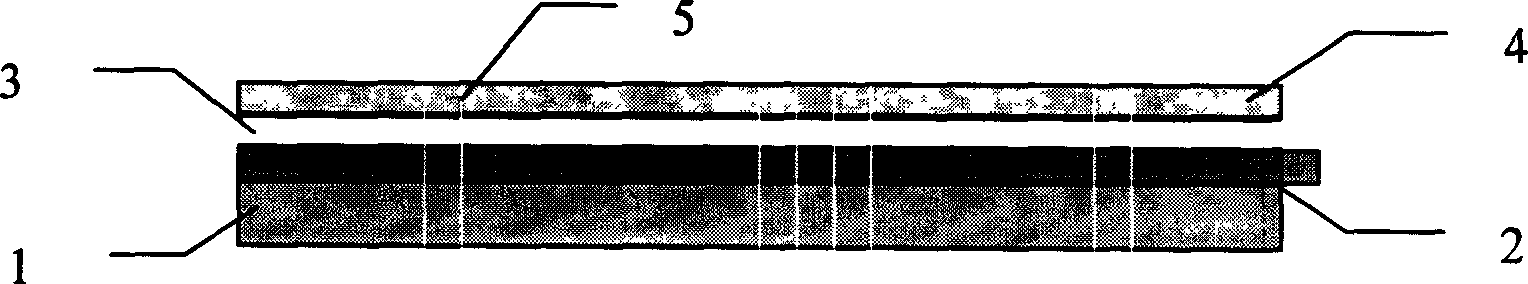

[0012] As shown in the figure, the present invention consists of low-weight coated paper 1, water-based latex layer 2, aluminum-coated layer 3, polymer resin layer 4 and air-permeable holes 5 formed by laser penetration, which are stacked in sequence.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to environmental protection type cigarette packing material. Its manufacturing includes the following steps: adopting high performance light weight coating paper and water latex; vacuum aluminum plating to plate aluminum at the surface of macromolecule resin material; wet composite for plated PET film and light weight coating paper; drying to separate them; laser drilling. The advantage of the invention is laser drilling to resume paper air permeability and reduce sucking resistance while smoking.

Description

technical field [0001] The invention relates to an environment-friendly cigarette packaging material, in particular to a laser perforated aluminum transfer cigarette tipping paper and a preparation method thereof. Background technique [0002] At present, most of the high-grade cigarettes produced by cigarette manufacturers use bronzing cigarette tipping paper to improve the decoration of the outer surface of cigarettes. Due to the use of a large amount of toluene as a paint thinner in the production process of the anodized aluminum used for bronzing, there are also serious toluene residues on the surface of the tipping paper after bronzing, especially when the cigarette tipping paper is in direct contact with human lips. Harmful to human health. The existing Chinese patent 02217116.9 cigarette anti-counterfeiting tipping paper provides a kind of tipping paper with a composite layer of a vacuum aluminized layer. Chinese patent 03222397.8 is a transfer cold ironing tipping ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D21H27/10B23K26/382D21H19/02D21H27/30

Inventor 甘君武颜金华尹国华包启泉

Owner DARE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com