A kind of regeneration method of metal filter tube

A technology of metal filtration and filter tubes, applied in the direction of filter regeneration, filtration separation, separation methods, etc., can solve problems such as no reusable value, achieve the effect of reusing and restoring air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

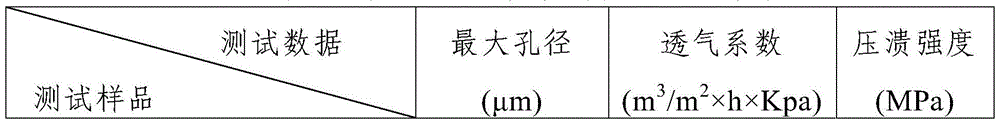

Embodiment 1

[0023] The metal filter tube of the present embodiment regeneration process is the stainless steel filter tube used in the purification process of the polysilicon process produced by the Siemens method, and the regeneration method of the metal filter tube of the present embodiment comprises the following steps:

[0024] Step 1. Wipe the outer surface of the metal filter tube until the solid intercepted matter accumulated on the outer surface of the metal filter tube is removed;

[0025] Step 2, place the metal filter tube wiped in step 1 in hydrofluoric acid for acid leaching treatment; the temperature of the acid leaching treatment is 30°C, the time of the acid leaching treatment is 6h, and the hydrofluoric acid The consumption is 10 times of metal filter tube quality, and the mass percentage concentration of described hydrofluoric acid is 10%;

[0026] Step 3. Under the condition that one end of the metal filter tube after the acid leaching treatment in step 2 is closed, fil...

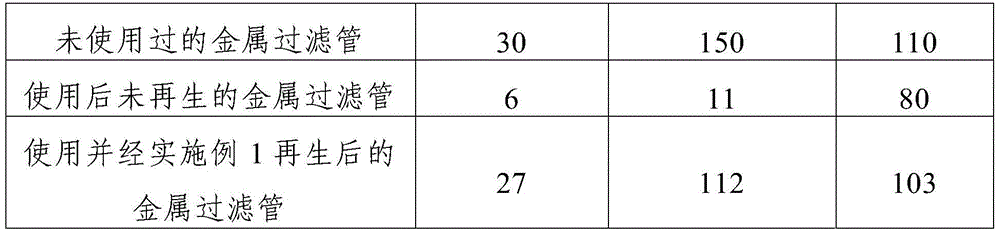

Embodiment 2

[0034] The metal filter tube of the present embodiment regeneration process is the stainless steel filter tube used in the purification process of the polysilicon process produced by the Siemens method, and the regeneration method of the metal filter tube of the present embodiment comprises the following steps:

[0035] Step 1. Wipe the outer surface of the metal filter tube until the solid intercepted matter accumulated on the outer surface of the metal filter tube is removed;

[0036] Step 2, place the metal filter tube wiped in step 1 in hydrofluoric acid for acid leaching treatment; the temperature of the acid leaching treatment is 40°C, the time of the acid leaching treatment is 4h, and the hydrofluoric acid The consumption is 12 times of metal filter tube quality, and the mass percentage concentration of described hydrofluoric acid is 15%;

[0037] Step 3. Under the condition that one end of the metal filter tube after acid leaching treatment in step 2 is closed, fill th...

Embodiment 3

[0044]The metal filter tube of the present embodiment regeneration process is the stainless steel filter tube used in the purification process of the polysilicon process produced by the Siemens method, and the regeneration method of the metal filter tube of the present embodiment comprises the following steps:

[0045] Step 1. Wipe the outer surface of the metal filter tube until the solid intercepted matter accumulated on the outer surface of the metal filter tube is removed;

[0046] Step 2. Put the metal filter tube wiped in step 1 into hydrofluoric acid for acid leaching treatment; the temperature of the acid leaching treatment is 50°C, the time of the acid leaching treatment is 0.5h, and the hydrofluoric acid The consumption of acid is 20 times of the metal filter tube quality, and the mass percentage concentration of described hydrofluoric acid is 1%;

[0047] Step 3. Under the condition that one end of the metal filter tube after the acid leaching treatment in step 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com