Measuring method for reflectivity of microwave absorption material

A technology of microwave absorbing materials and measurement methods, which is applied in the direction of material analysis, measurement devices, and analysis materials using microwave means. It can solve the problems of large size, expensive, and difficult to ensure the flatness of the measurement surface, so as to achieve simple operation and avoid errors. , the effect of low measurement requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

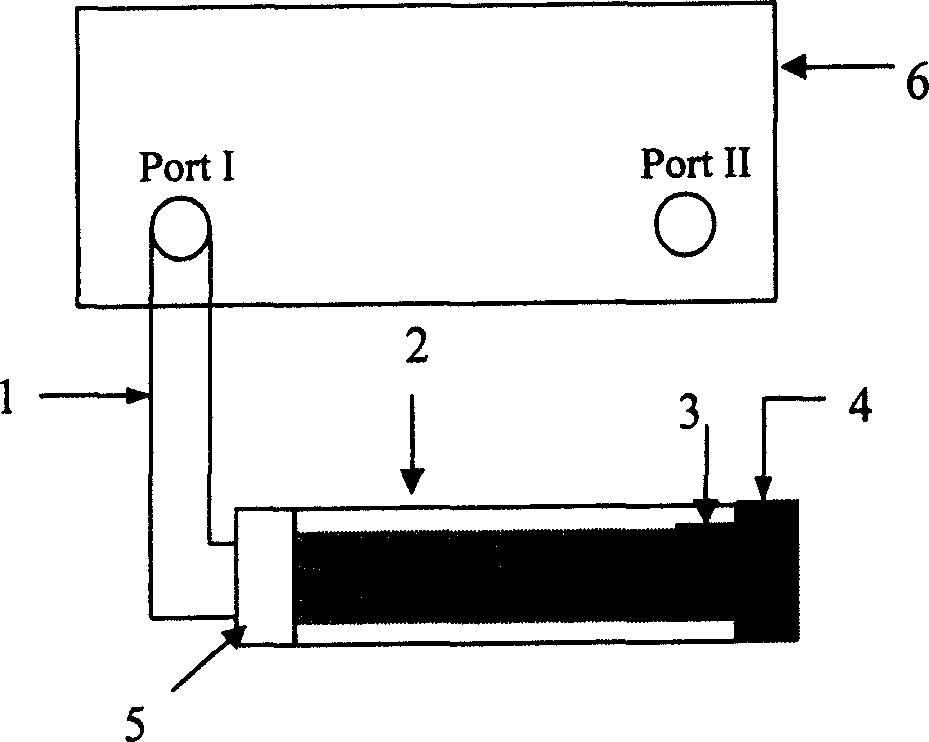

[0061] Select HP8722ET vector network analyzer 6, APC-7mm coaxial air line 2, test cable 1 and APC-7 adapter 5 to test the reflectivity of the silicone rubber absorbing material containing 80% ferrite.

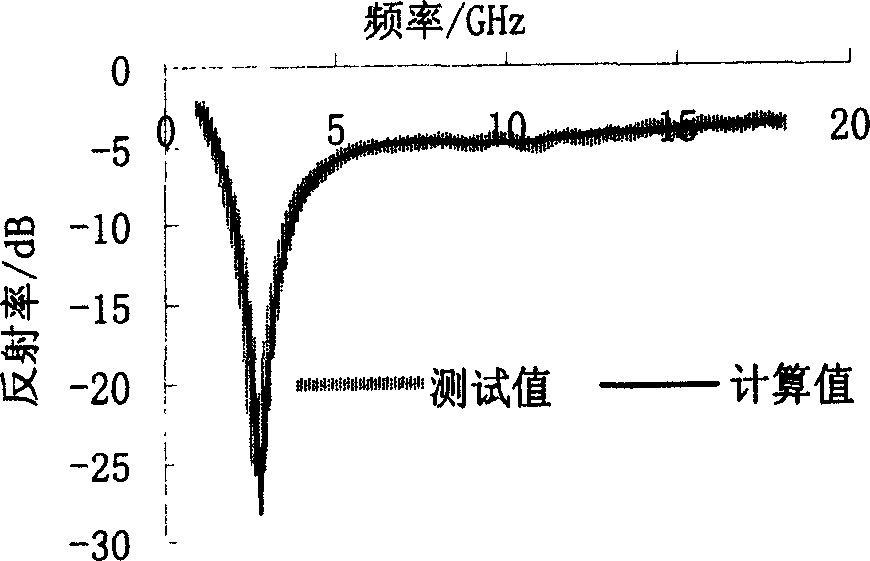

[0062] Choose HP8722ET network analyzer 6 and APC-7mm coaxial air line 2, and make the absorbing material into a concentric annular sample 3 with an outer diameter of 7mm, an inner diameter of 3.04mm, and a thickness of 3mm, so that it is compatible with the APC-7mm coaxial air line 2 are used in conjunction with each other, and ensure that the dimensional error of the inner and outer diameter of the sample, concentricity, perpendicularity between the end face and the axis, and the flatness of the end face are less than 0.05mm. Its measurement diagram is shown in figure 1 . Assemble the above test cable 1, adapter 5 and network analyzer 6 to determine the measurement parameters. The measurement parameters mainly include start frequency: 2GHz, stop frequency: 18GHz, number of ...

Embodiment 2

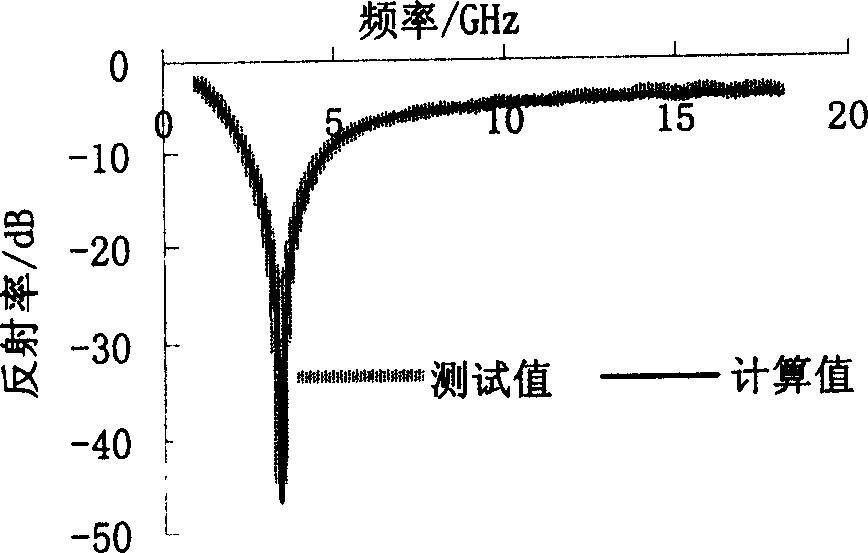

[0064] Select HP8757 scalar network analyzer 6, APC-3.5mm coaxial air line 2, test cable 1 and APC-3.5 conversion connector 5 to test the reflectivity of SiC ceramic absorbing material, and first make the absorbing material into an outer diameter 3.5mm, 1.52mm inner diameter, 15mm thick concentric annular sample 3, make it used in conjunction with APC-3.5mm coaxial air line 2, and ensure the size error of the inner and outer diameter of the sample, concentricity, perpendicularity between the end face and the axis And the flatness of the end face is less than 0.05mm.

[0065] Assemble the above-mentioned test cable 1, adapter 5 and network analyzer 6 to determine the measurement parameters. The measurement parameters mainly include start frequency: 2GHz, stop frequency: 18GHz, number of measurement points: 201, intermediate frequency bandwidth: 500Hz, output power: 0dBm and the average factor: 50, and measure and calibrate the test system composed of the three; assemble the cal...

Embodiment 3

[0067] The microwave absorbing material prepared with 60% nano-iron powder and epoxy resin was made into a concentric annular sample 3 with an outer diameter of 7mm, an inner diameter of 3.04mm, and a thickness of 3.2mm. The axial air line 2, the metal short circuit 4, the test cable 1 and the APC-7 type conversion joint 5 measure the reflectivity of the concentric annular sample 3, the measurement method is as in Example 1, and the measurement parameters mainly include the starting frequency: 8GHz, Termination frequency: 18GHz, number of measurement points: 201, intermediate frequency bandwidth: 300Hz, output power: 0dBm and average factor: 60, and then prepare a 180×180×3.2mm flat plate containing 60% nano-iron powder and epoxy resin to The bow method introduced in literature [2, 5] is used for measurement; then the reflectance value of the sample is calculated by the theoretical formula in literature [8], and the reflectance values obtained by the above three methods are d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com