Automatic tuning and small current grounding failure wire selection system of master slave extinction coil

A low-current grounding, arc suppression coil technology, applied in the fault location, protection of response to fault current, etc., can solve the problems of poor arc suppression effect, inability to operate, complex arc suppression coil structure, etc., and achieve reliable arc suppression. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

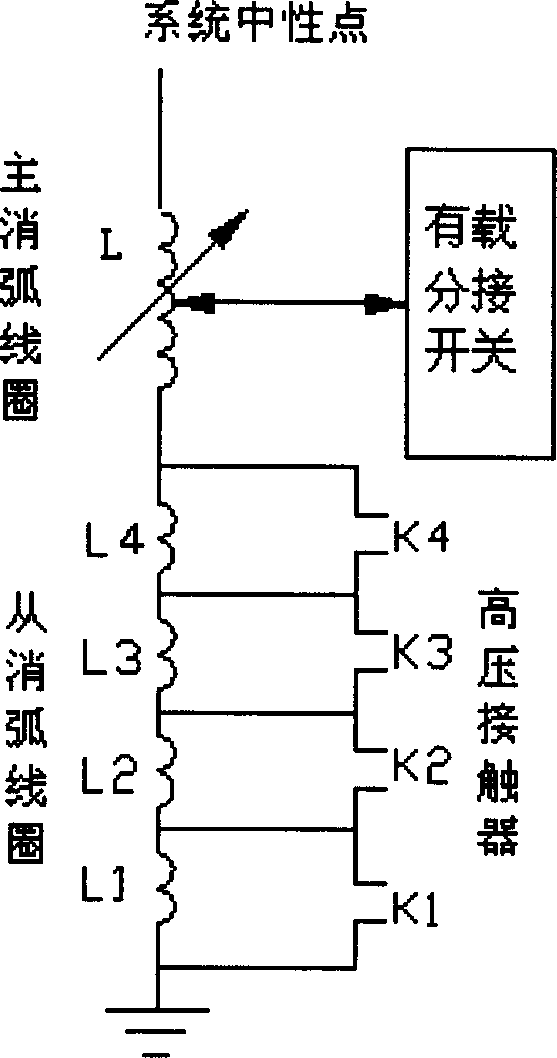

[0021] The structure of the master-slave arc suppression coil is as follows: figure 1 shown. L1, L2, L3, and L4 are four parallel reactors, and the reactive capacity of the four reactors is distributed according to the ratio of 1:2:4:8. k1, k2, k3, and k4 are vacuum high-voltage contactors, which are respectively connected to the system in parallel with the reactor, so that the switching control of the reactor can be realized through the operation of the vacuum high-voltage contactor. There are sixteen combinations of four reactors, which can form 16 evenly distributed reactor capacities. The design of each reactor of the slave arc suppressing coil is carried out according to the principle of making the ground current after compensation less than 1A (if there are two slave arc suppressing coils, the ground current is less than 2A), and such gear distribution meets the needs of tuning precision.

[0022] The arc suppression coil adopts a master-slave structure. When the syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com