Process for extracting sea-cucumber oligopeptide and sea-cucumber polysaccharide from sea-cucumber deep processing by-product

A technology for sea cucumber oligopeptide and sea cucumber polysaccharide, which is applied in the field of extracting sea cucumber oligopeptide and sea cucumber polysaccharide, can solve the problems of increasing the cost of sea cucumber polysaccharide, lack of systematic screening of enzymes, polluting the environment, etc., so as to improve product color, save alcohol and save energy. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

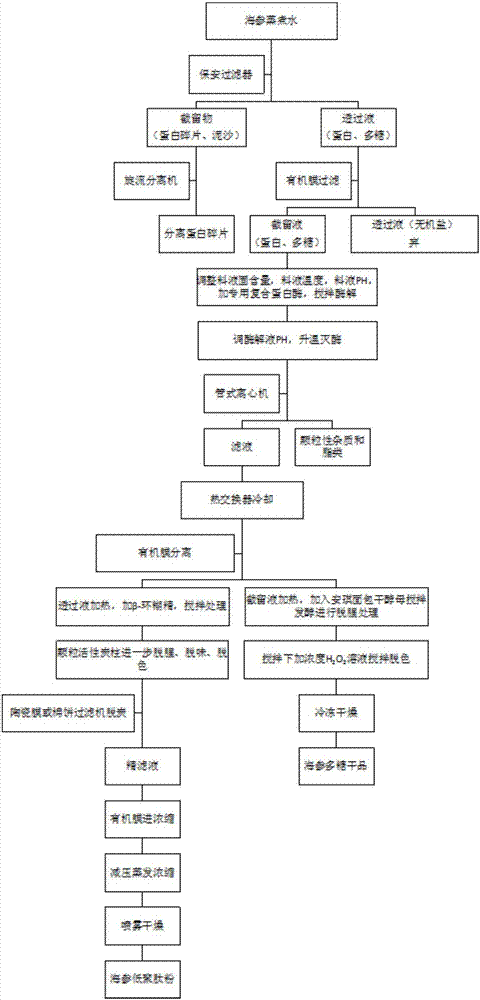

Image

Examples

Embodiment

[0043] Step a, take sea cucumber cooking water or soaking water 15m 3 Filter with a security filter to obtain solids and liquids; the solids are separated from the silt by a cyclone separator to obtain 2.13 kilograms of sea cucumber fragment particles;

[0044] Step b, the filtrate is concentrated through an organic membrane with a pore size of 10kDa-20kDa, and the retentate is separated by adding an appropriate amount of pure water 4-5 times, and the permeate is separated with AgNO 3 A small amount of turbidity was detected by the method, indicating that the removal rate of inorganic salts met the requirements, and the retentate (concentrate) was 1.35m 3 , the concentration factor is 11.11 times. The protein content in the retentate was determined to be 6.72%, and the polysaccharide content was 9.38%;

[0045] Step c, add the sea cucumber pieces to the retentate and stir evenly; raise the temperature of the material to 47°C ± 1°C; use 20% NaOH seasoning solution pH8.0 ± 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com