Chain type digger for self-propelled sea cable burying machine

A buried machine and self-propelled technology, applied in the direction of earth mover/excavator, construction, etc., can solve the problems of complex connection type, complex structure, cost increase, etc., and achieve wide application range, safe and reliable work, and easy replacement The effect of pretending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

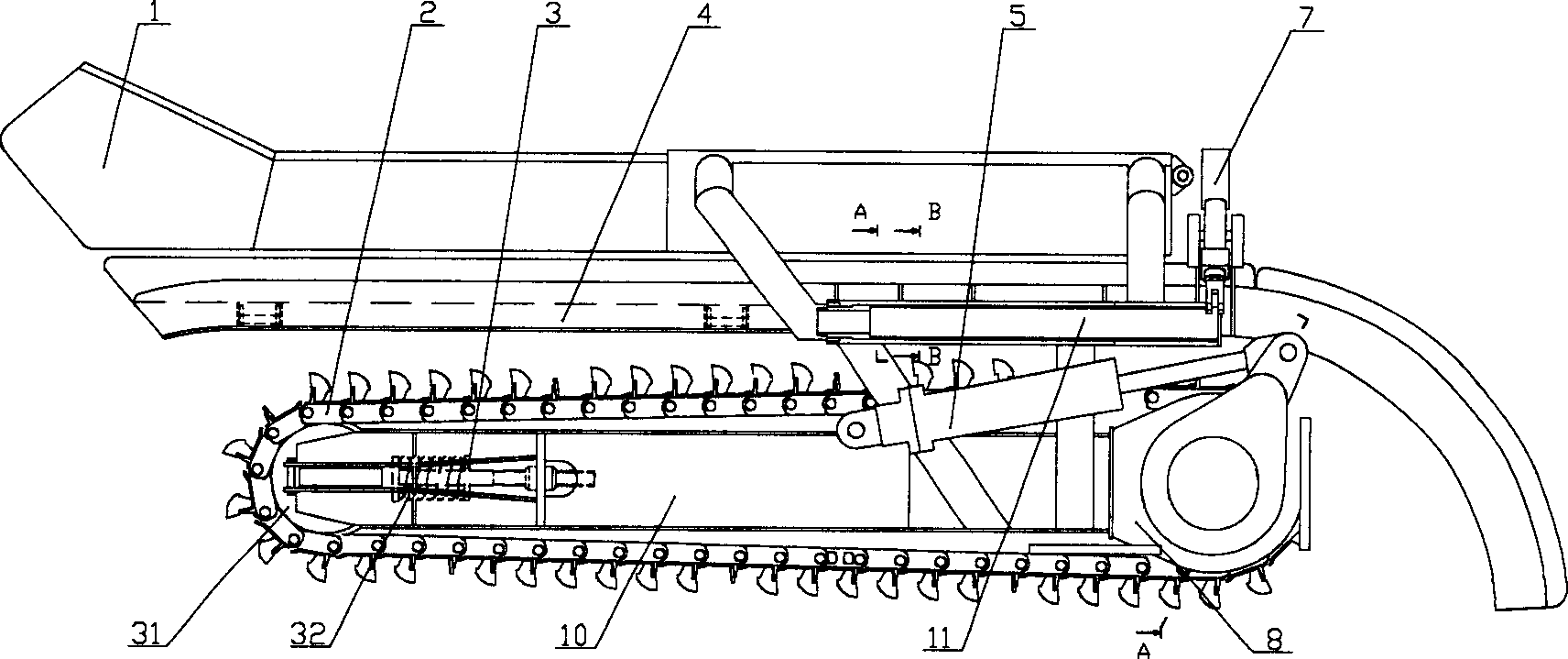

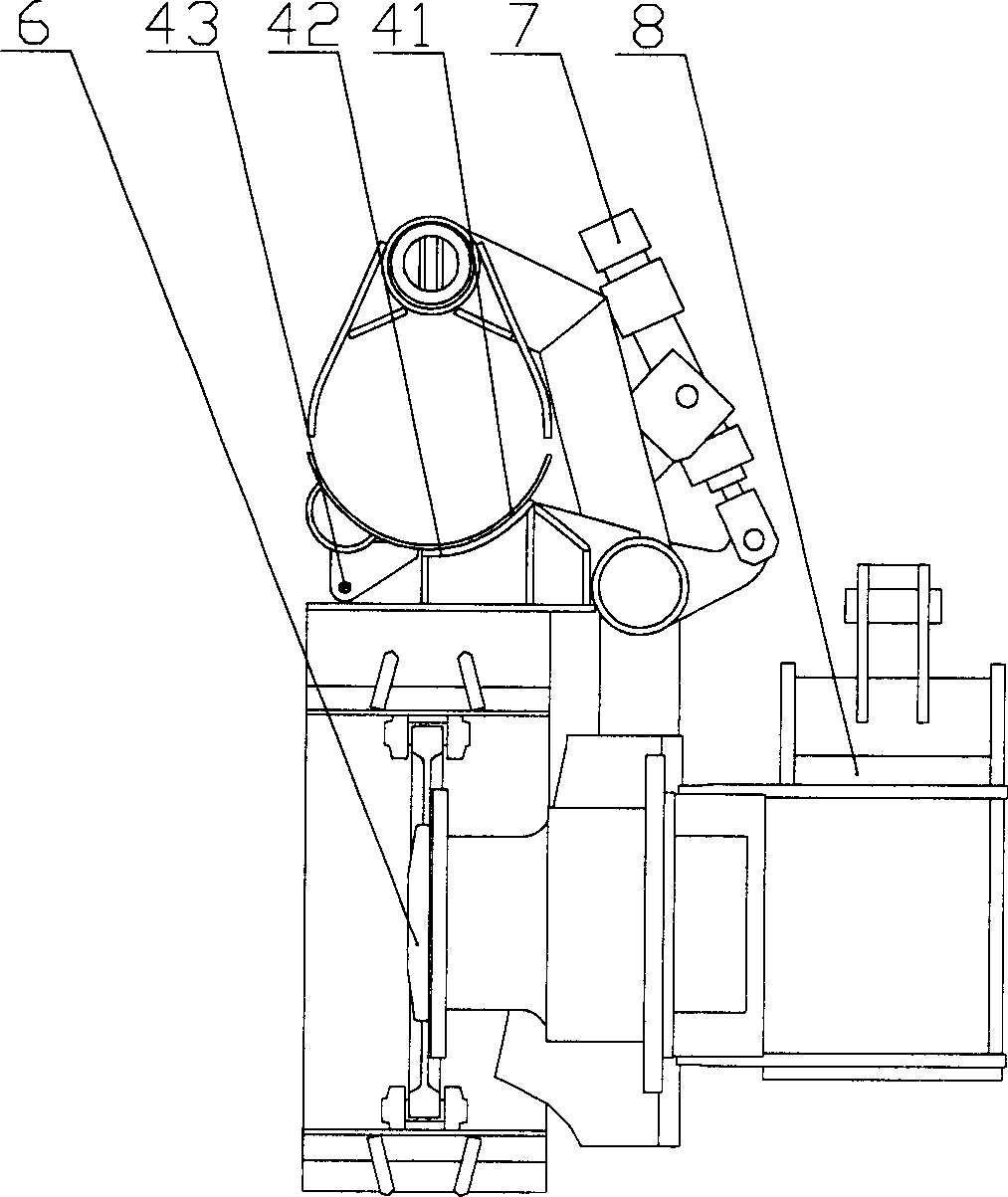

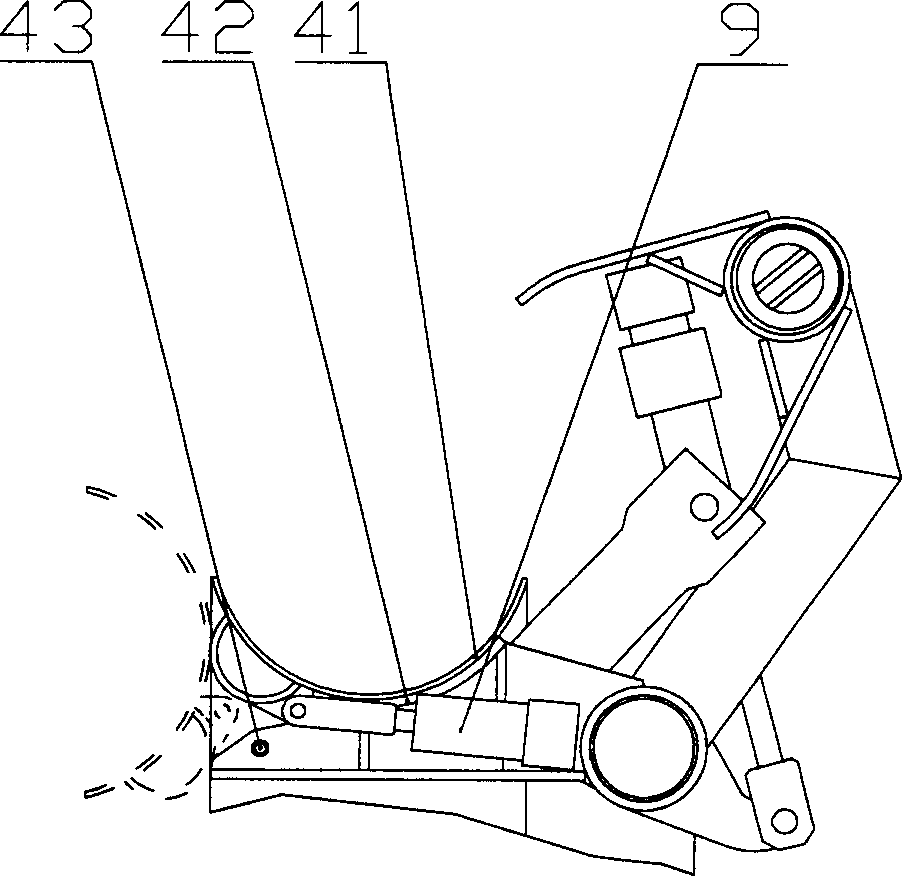

[0016] like figure 1 , 2 , 3, the chain excavation tool of the present invention is mainly composed of a depressor 1, an excavation chain 2, a chain tensioner 3, a lower bracket 4, a depressing oil cylinder 5, a hydraulic motor and a sprocket 6, and an opening cover in structure. Composed of oil cylinder 7, slewing support 8, turning oil cylinder 9, and pressing arm 10, wherein the pressing arm 10 is a box structure, the whole is wrapped by the chain of excavating chain 2, and the front end is a tubular structure, which is plugged with slewing support 8 Together constitute the rotary shaft, the rotary support 8 is installed on the right frame of the buried locomotive body with bolts through the horizontal and vertical connecting plates, and the hydraulic motor in it is connected with the sprocket of the excavation chain 2 through the flange (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com