Light emitting screen structure and image forming apparatus

A technology of light-emitting screens and light-emitting elements, applied in image/graphic display tubes, discharge tubes, screen tubes, etc., can solve problems such as uneven brightness, device damage, and insufficient solutions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

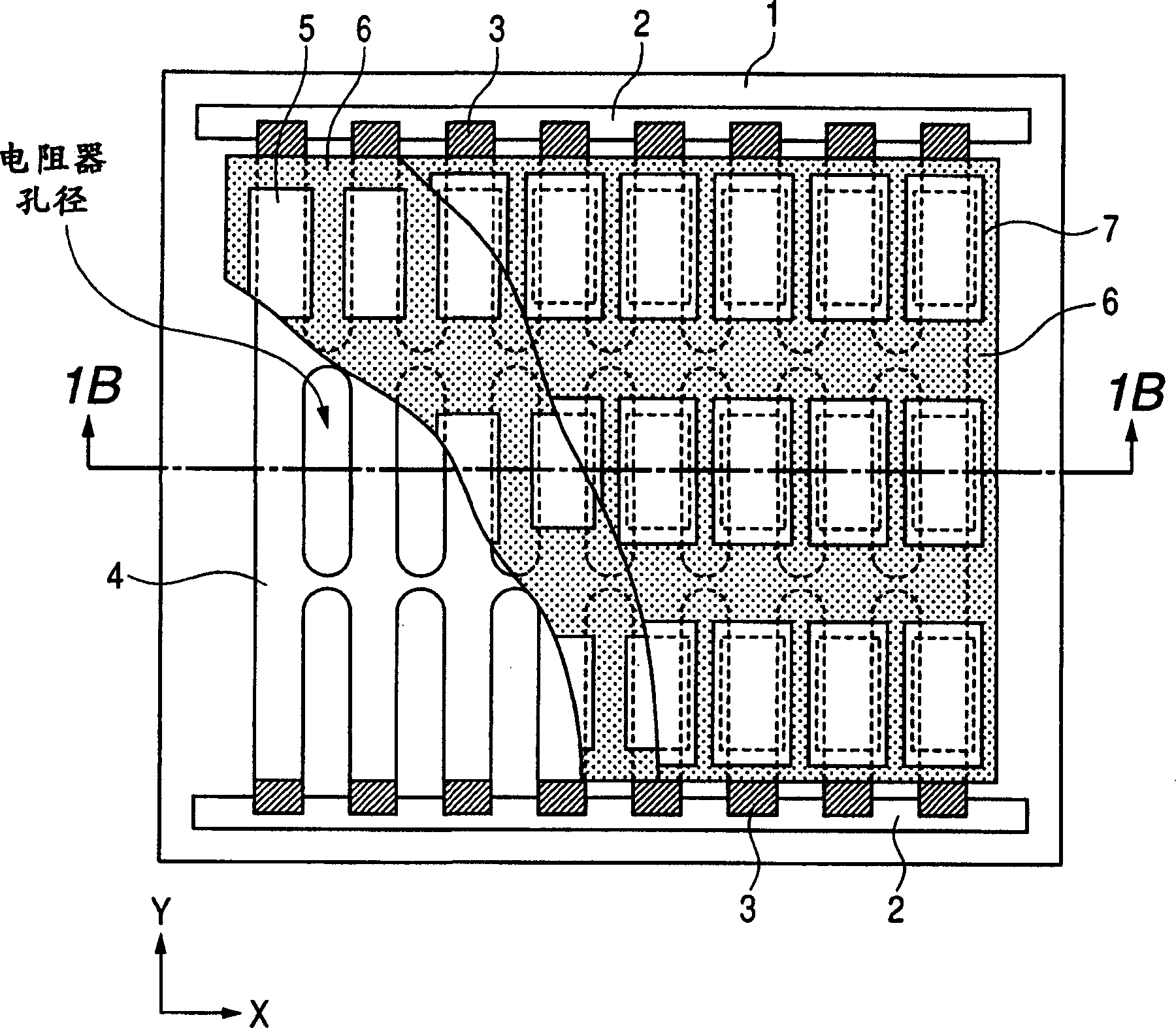

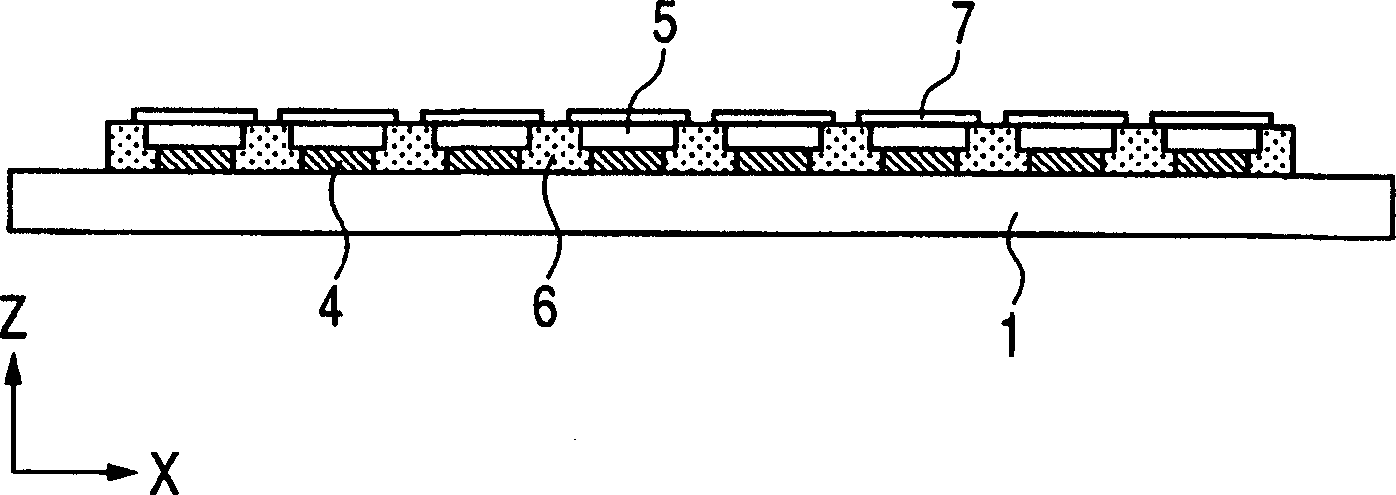

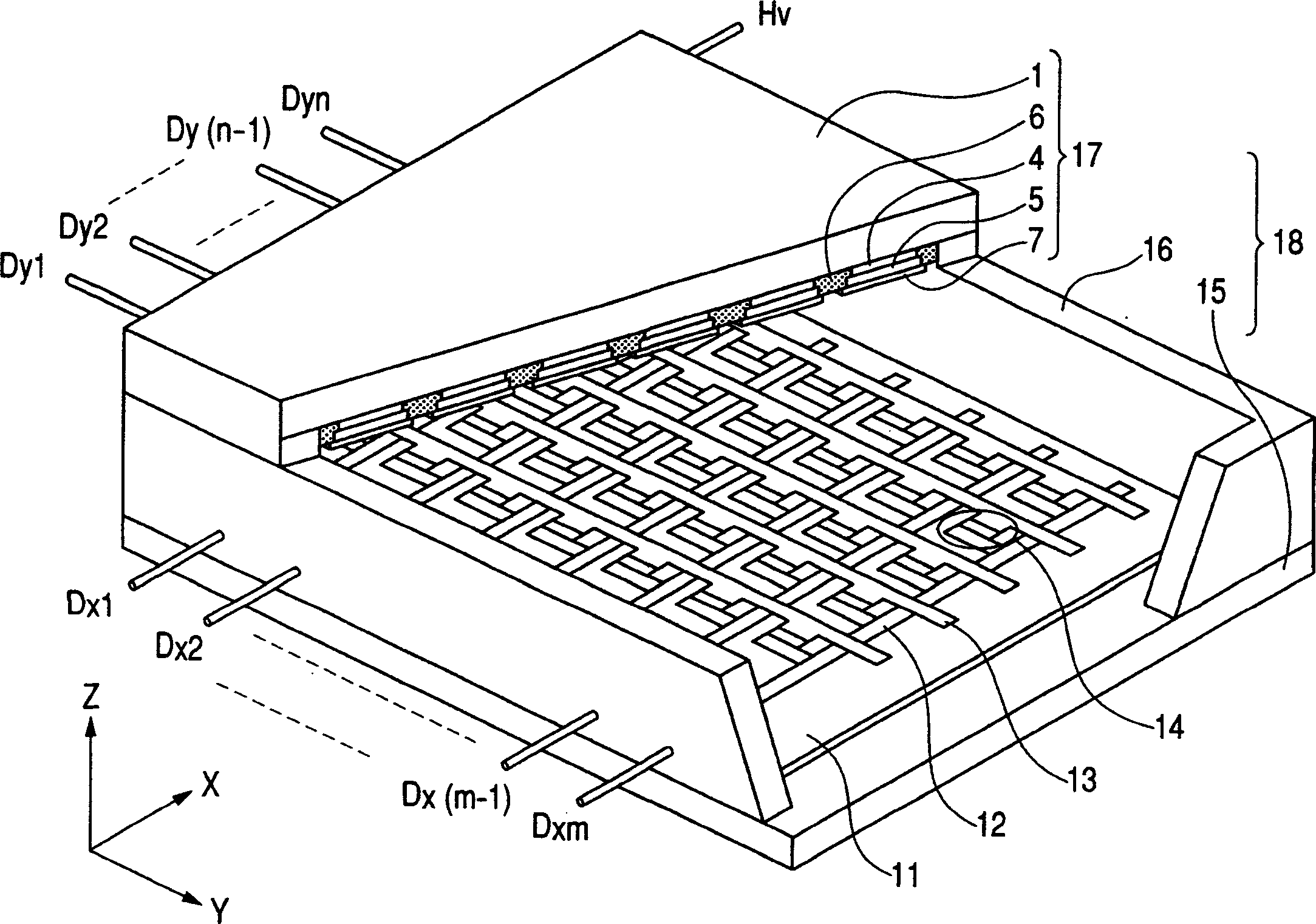

[0062] have as Figure 1A and 1BA light-emitting substrate of the configuration shown was prepared in the following procedure.

[0063] On a glass substrate 1, an ITO film was formed on the entire upper surface, and a grid-shaped pattern was formed by lithographic printing processing, so that a resistor element 4 was obtained. Then, a patterned NiO film was formed as the connection resistor 3 . Then, the common electrode 2 is formed with Ag paste so as to be in contact with all the connection resistors 3 . Then, NP-7803 (manufactured by Noritake Kizai Co., Ltd.) was printed as a black element 6 on the patterned ITO film, followed by coating and baking of red, green and blue phosphors 5 . Finally, an island-shaped metal backplane 7 is formed on the phosphor 5 by vacuum evaporation.

[0064] In this example, a glass substrate PD200 manufactured by Asahi Glass Co., Ltd. with a thickness of 2.8 mm was used. In addition, in the matrix-shaped resistor element 4, the width of th...

example 2

[0072] preparation Figure 3A and 3B The light-emitting substrate in the configuration shown. This example is similar to Example 1, except that three red, green and blue phosphors 5 arranged continuously along the X direction are covered by a single metal back plate 7 together.

[0073] In this example, the width of the Y-direction strip portion extending in the Y-direction of the ITO resistor is 100 μm, and the thickness is 100 nm, and the sheet resistance of the ITO film is adjusted to 30 kΩ / square, so that the adjacent metal in the Y-direction A resistance of about 120 kΩ is obtained between the backplanes 7 . In addition, the width of the ITO film extending in the X direction was 50 μm, so that a resistance (individual resistance) of about 800 kΩ was obtained between adjacent metal back plates in the X direction. In addition, the intersecting portion of the grid pattern of the resistance element 4 has a radius of curvature of 50 μm, matching the narrow strip width in th...

example 3

[0080] preparation Figure 4A and 4B The light-emitting substrate in the configuration shown. This example is similar to Example 1, except that the resistor elements 4 are located below the black elements 6, and two Y-direction strip portions of the resistor elements 4 are provided for each metal backplane along the Y-direction.

[0081] In this example, the width of the ITO resistor and the strip portion in the Y direction is 50 μm, and the sheet resistance of the ITO film is adjusted to 30 kΩ / square, thereby obtaining a resistance of about 120 kΩ between adjacent metal backplanes 7 in the Y direction. resistance. In addition, the width of the X-direction stripe portion of the ITO film was 30 μm, thereby obtaining a resistance (individual resistance) of about 800 kΩ between adjacent metal back plates in the X direction. In addition, the intersecting portion of the grid pattern of the resistance element 4 has a radius of curvature of 50 μm, matching the narrow strip width i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com