Shield wire, housing connected with same, connecting method thereof and shield wire unit

A wire and box technology, which is applied to power cables with shielding/conducting layers, conductive connections, and electrical component connections, etc., can solve the problems of 351 micro-cracks in the coating layer, heating of braided shielded wires, and increased resistance value. Achieving excellent results and good connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] Next, a preferred embodiment of the present invention will be described with reference to the accompanying drawings.

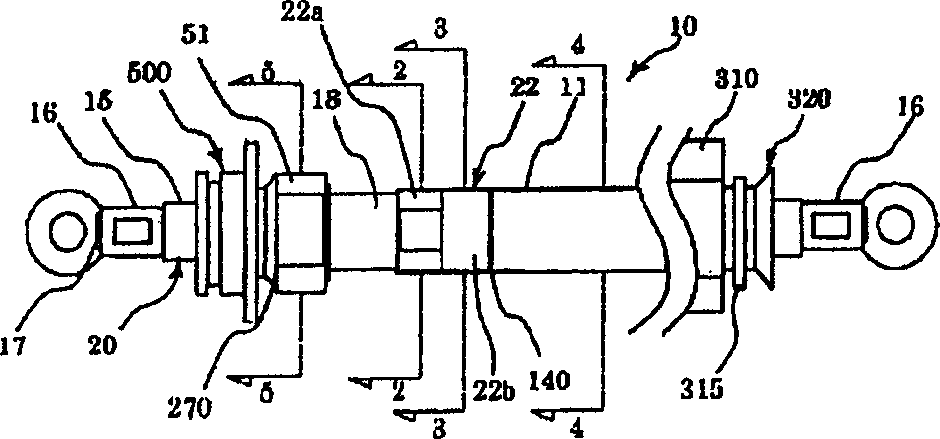

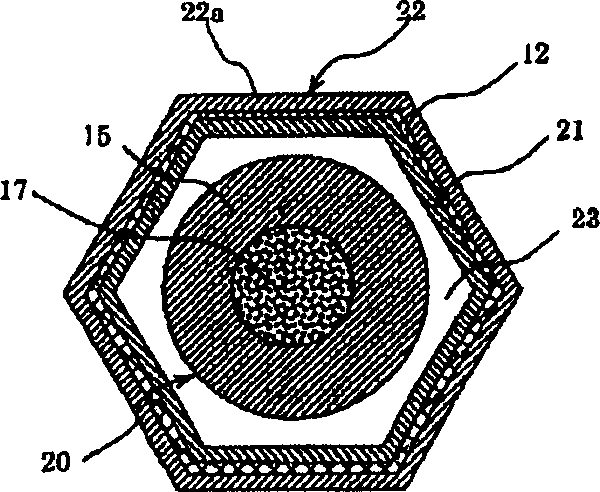

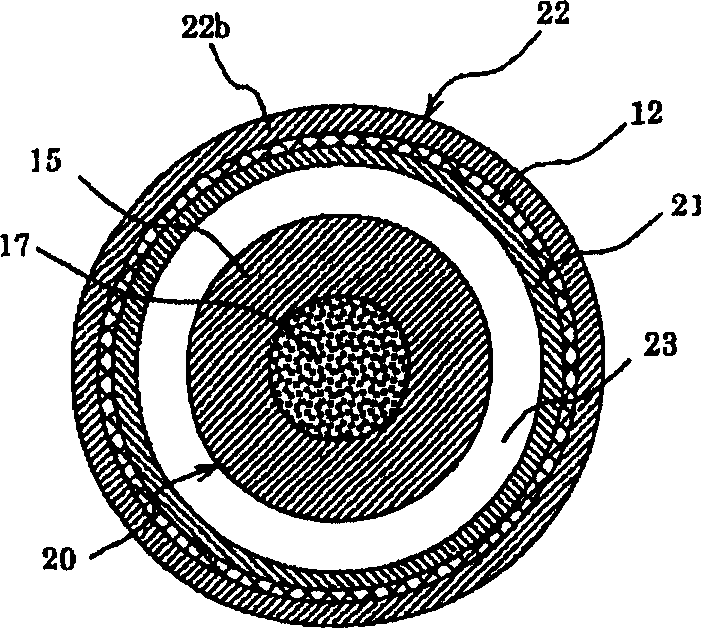

[0087] Such as figure 1 As shown, the shielded electric wire of this embodiment is provided with a shielding member around a conductive body 20 formed of a conductor 17 made of a single wire material or a strand material covered by an insulator 15 . The shielded wire is connected to connection terminals 16, 16 at both ends thereof. one end ( figure 1 The connection terminal 16 on the left side in the middle) is connected to one side of the converter described later, for example, and the other end ( figure 1 The connection terminal on the right side in ) is connected to, for example, a transmission described later.

[0088] The shielding components consist of such Figure 6 Shown barrel 50 and Figure 12 The metal tube 11 shown constitutes. The cylinder body 50 and the metal pipe 11 are butt-connected, and the cylinder body 50 and the metal pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com