Substrate processing apparatus and transfer positioning method thereof

A substrate processing device and positioning method technology, applied in the direction of conveyor objects, transportation and packaging, electrical components, etc., can solve the problems that it is impossible to fully ensure the height position accuracy, time and labor are required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

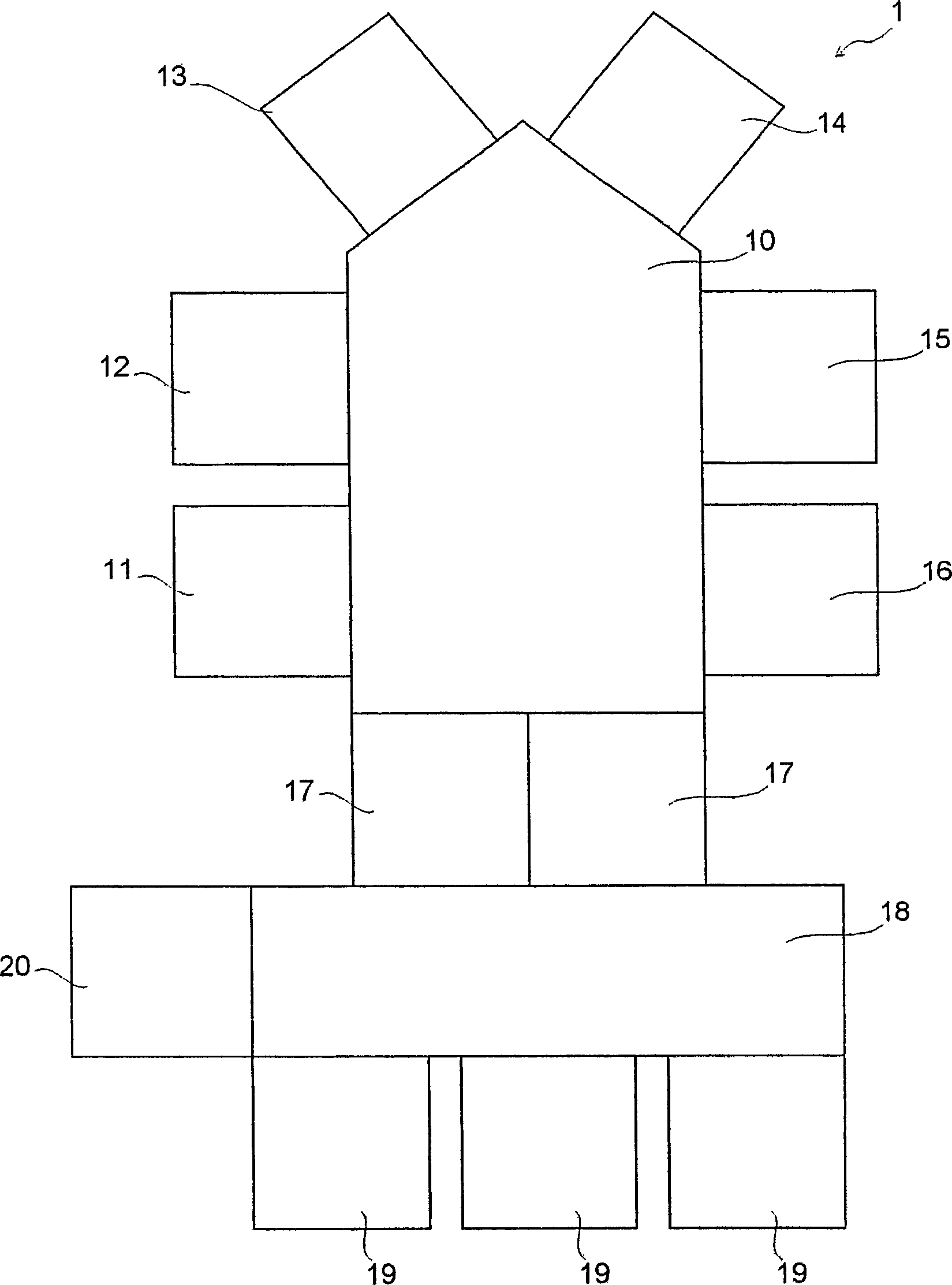

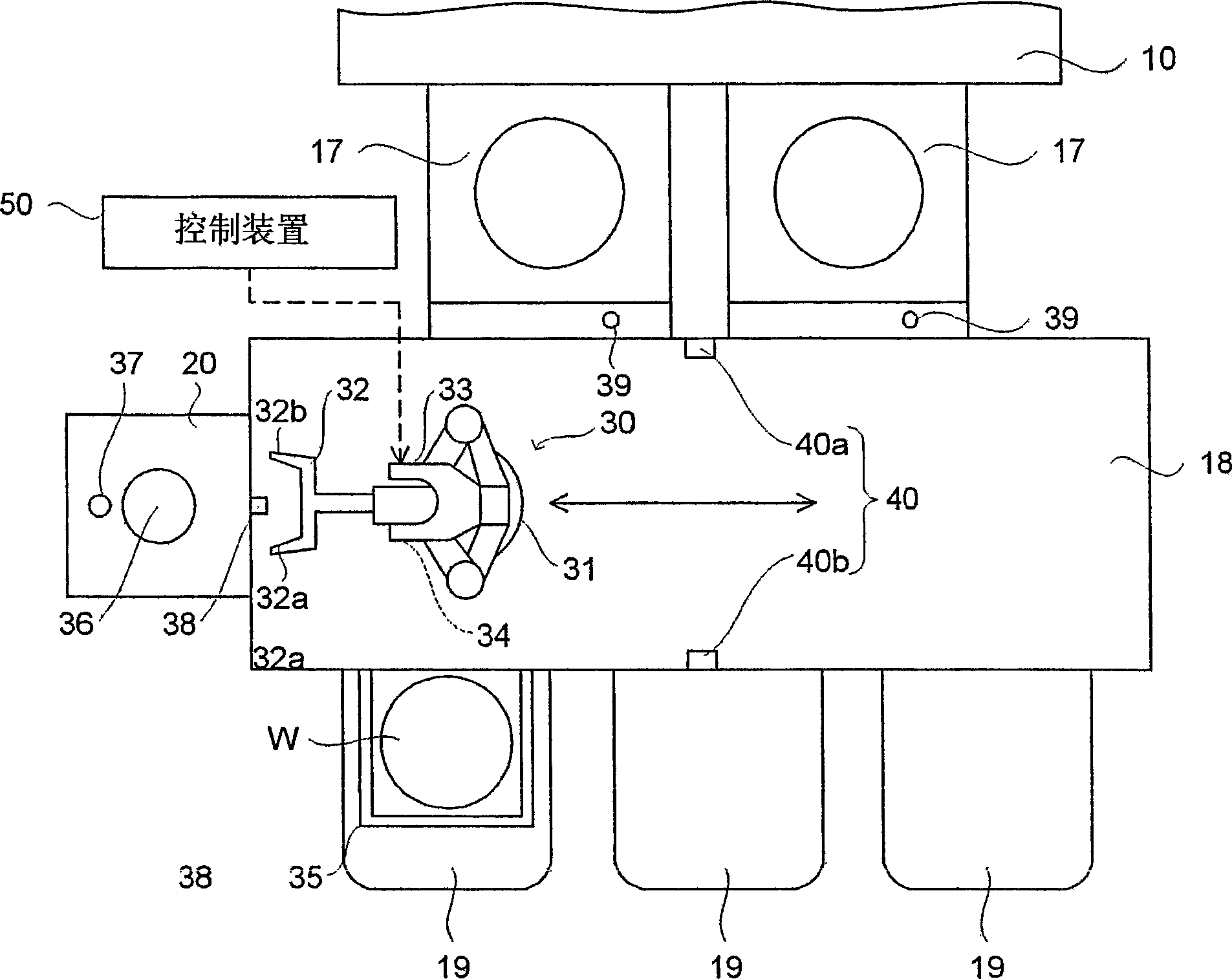

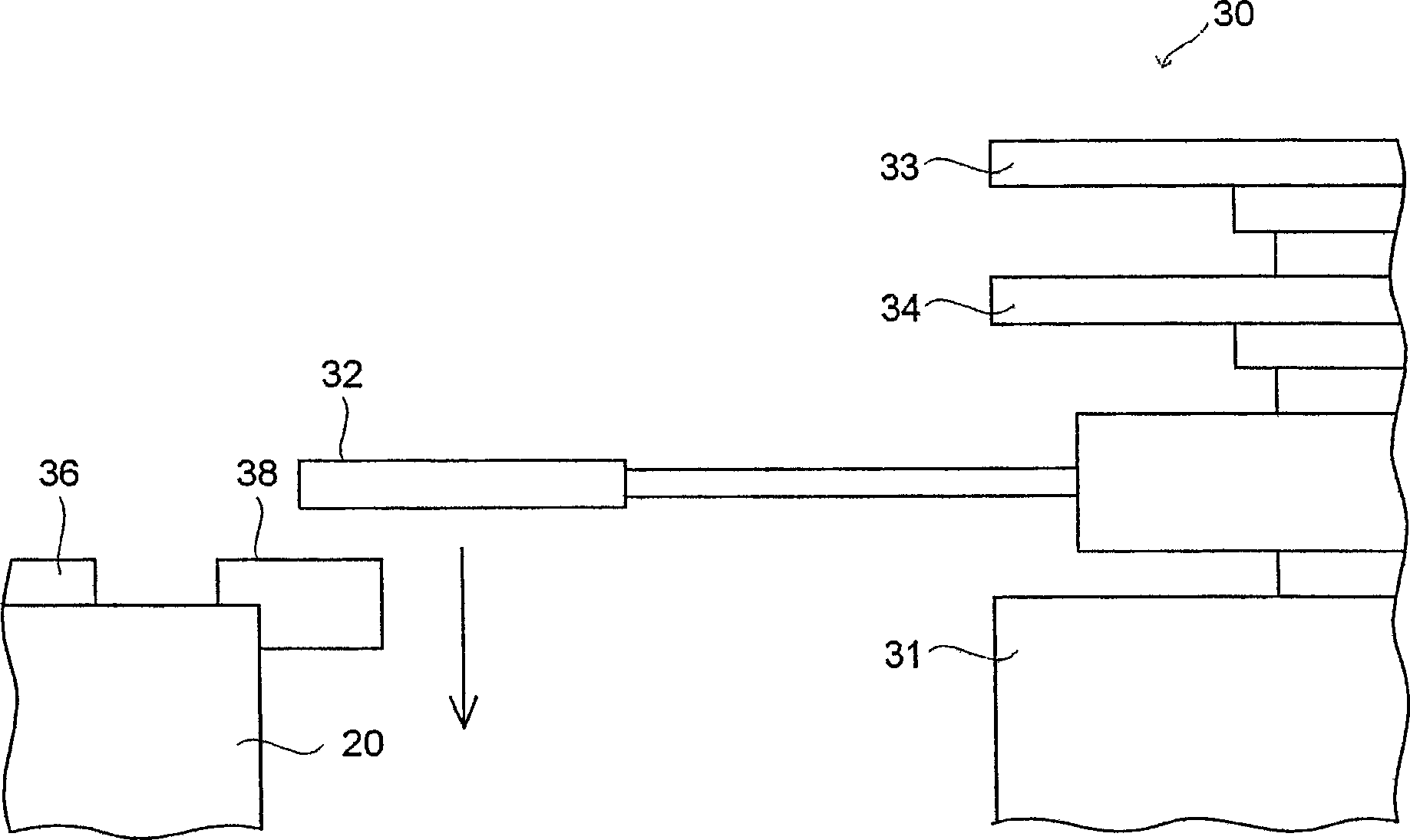

[0019] Hereinafter, the present invention will be described in detail as one embodiment with reference to the drawings. figure 1 Shown is the overall structure of a substrate processing apparatus according to one embodiment of the present invention. Such as figure 1 As shown, a vacuum transfer chamber 10 is provided in the central part of the substrate processing apparatus 1, and a plurality of (six in this embodiment) vacuum processing chambers ( processing chamber) 11-16.

[0020] Two load locking chambers (load locking chambers) 17 are provided on the front side (lower side in the figure) of the vacuum transfer chamber 10 . A transfer chamber 18 for transferring the semiconductor wafer W in the atmosphere is provided on the front side (lower side in the figure) of these load lock chambers 17 . On the further front side (lower side in the figure) of the transfer chamber 18, a plurality of figure 1 There are three of them) are provided with a loading unit 19 serving as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com