Deflection magnetic field type vacuum arc vapor deposition device

A deflecting magnetic field, vacuum arc technology, applied in the direction of vacuum evaporation coating, circuit, discharge tube, etc., can solve the problem of difficult to form compound film and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

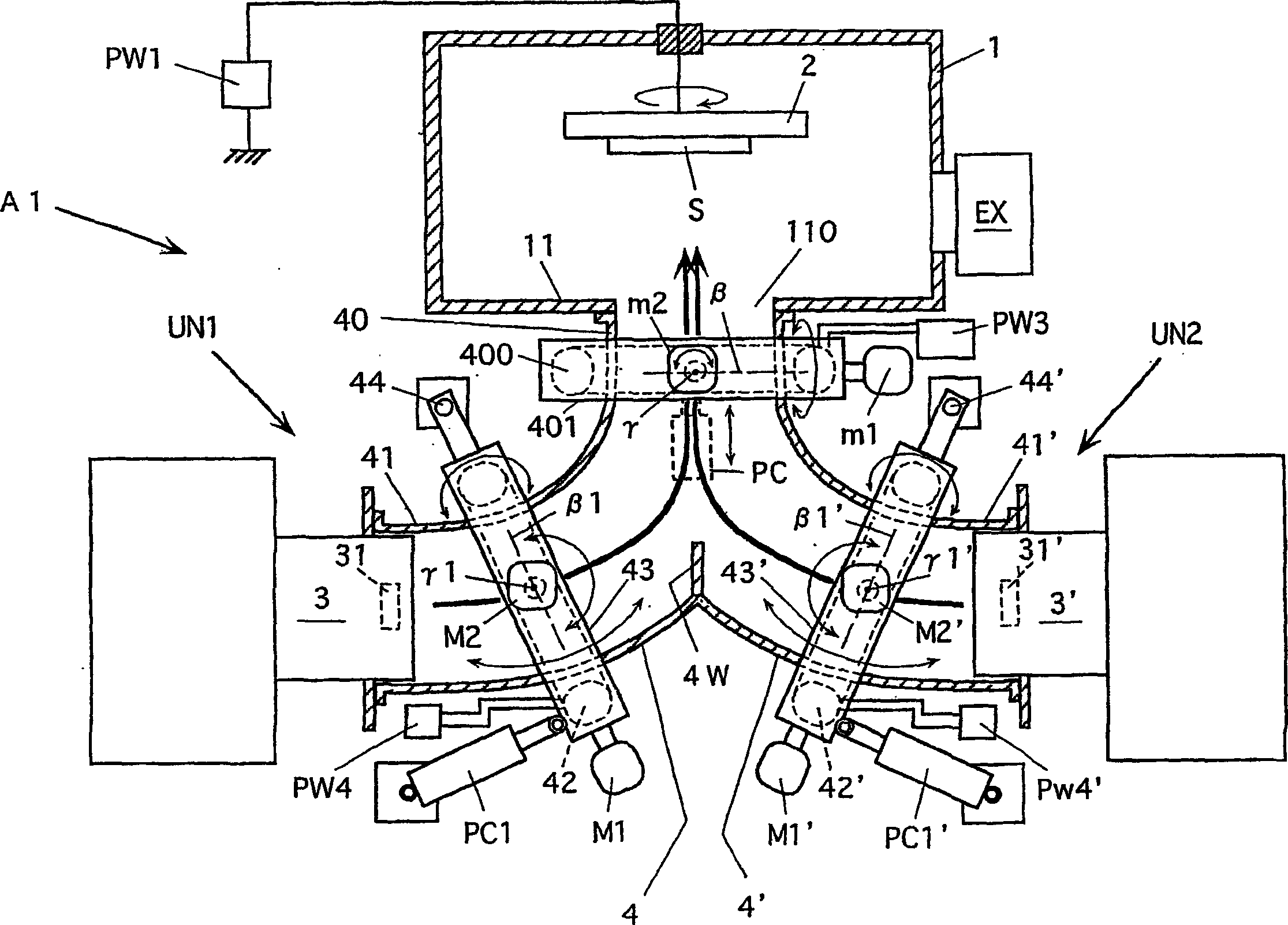

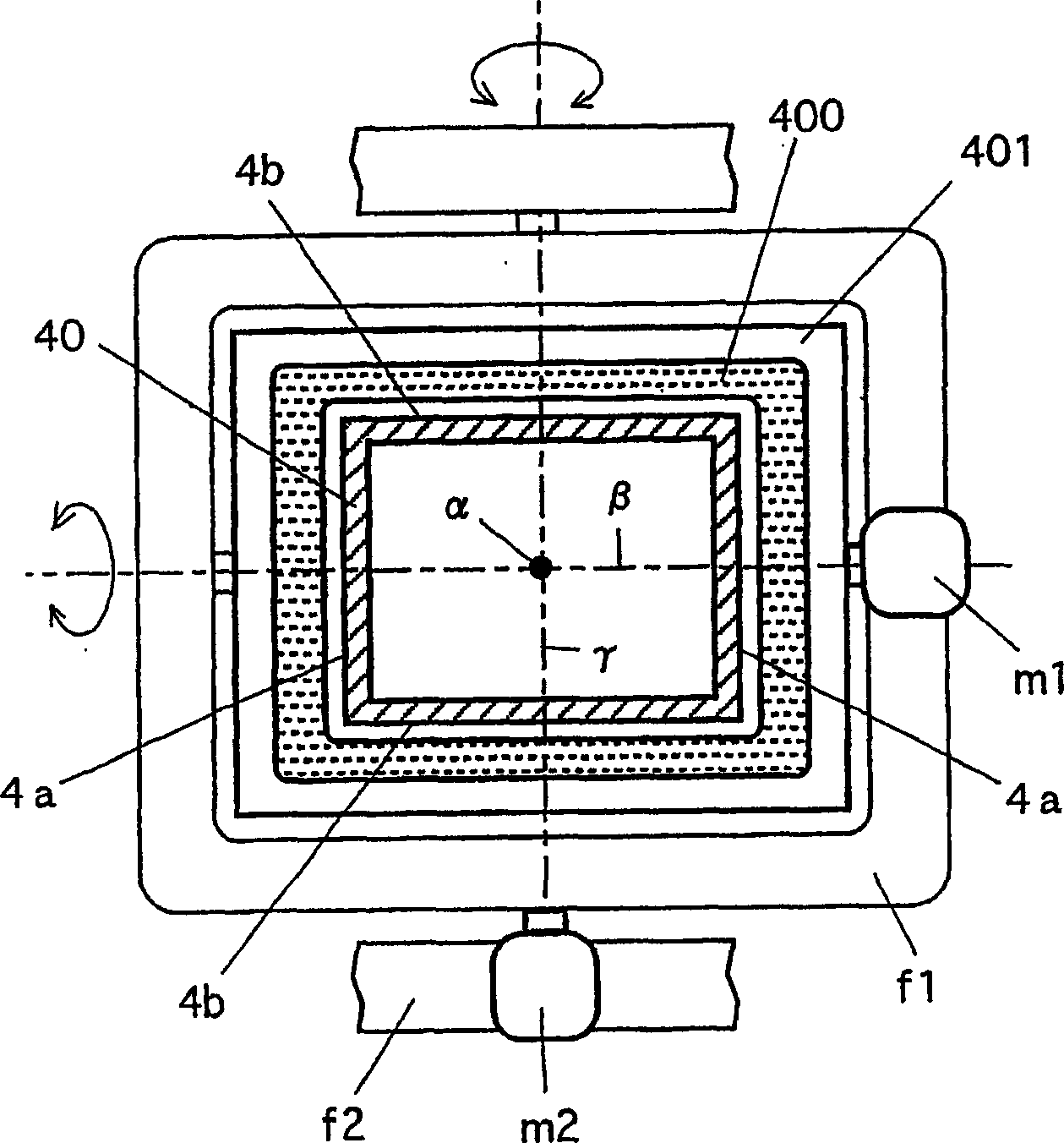

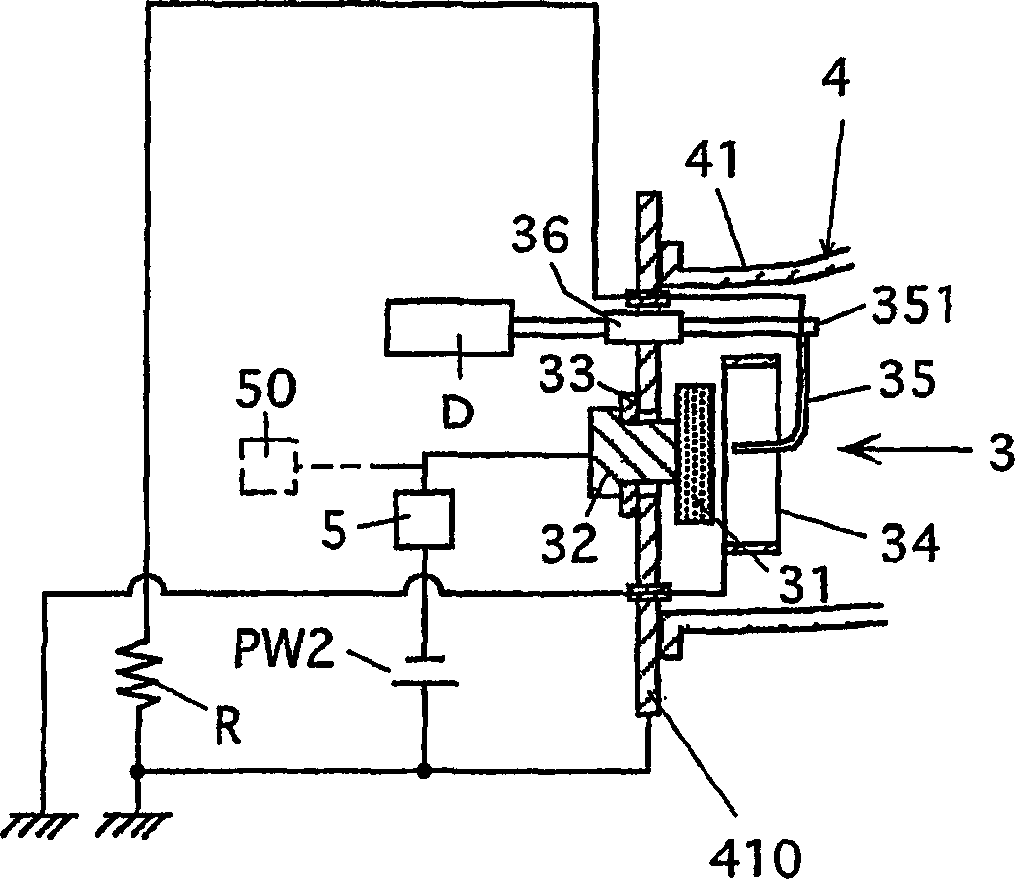

[0033] The deflection magnetic field type vacuum arc evaporation device of the present invention basically has a plurality of evaporation units, each of which includes an evaporation source that utilizes vacuum arc discharge between the anode and the cathode to evaporate and simultaneously ionize the cathode material, And the bending of one or more than two deflection magnetic field forming members that make the cathode material ionized by the evaporation source fly to the bracket so as to form a film containing the constituent elements of the cathode material on the film-formed part supported by the bracket lauter tank.

[0034] Then, the respective curved filter tanks of the plurality of evaporation units are formed such that the tank ends facing the bracket and the tank ends of other curved filter tanks facing the bracket are common tank ends, and At least one evaporation source is provided at opposite ends of the filter tank.

[0035] In addition, a magnetic field forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com