Fluid cooling device

A fluid cooling and fluid technology, which is applied in fluid pressure actuators, oil supply tank devices, engine cooling, etc., can solve the problems of affecting the cooling capacity of heat exchangers and the loud operation of fluid cooling devices, so as to increase the possibility of modeling performance, save space, and improve suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

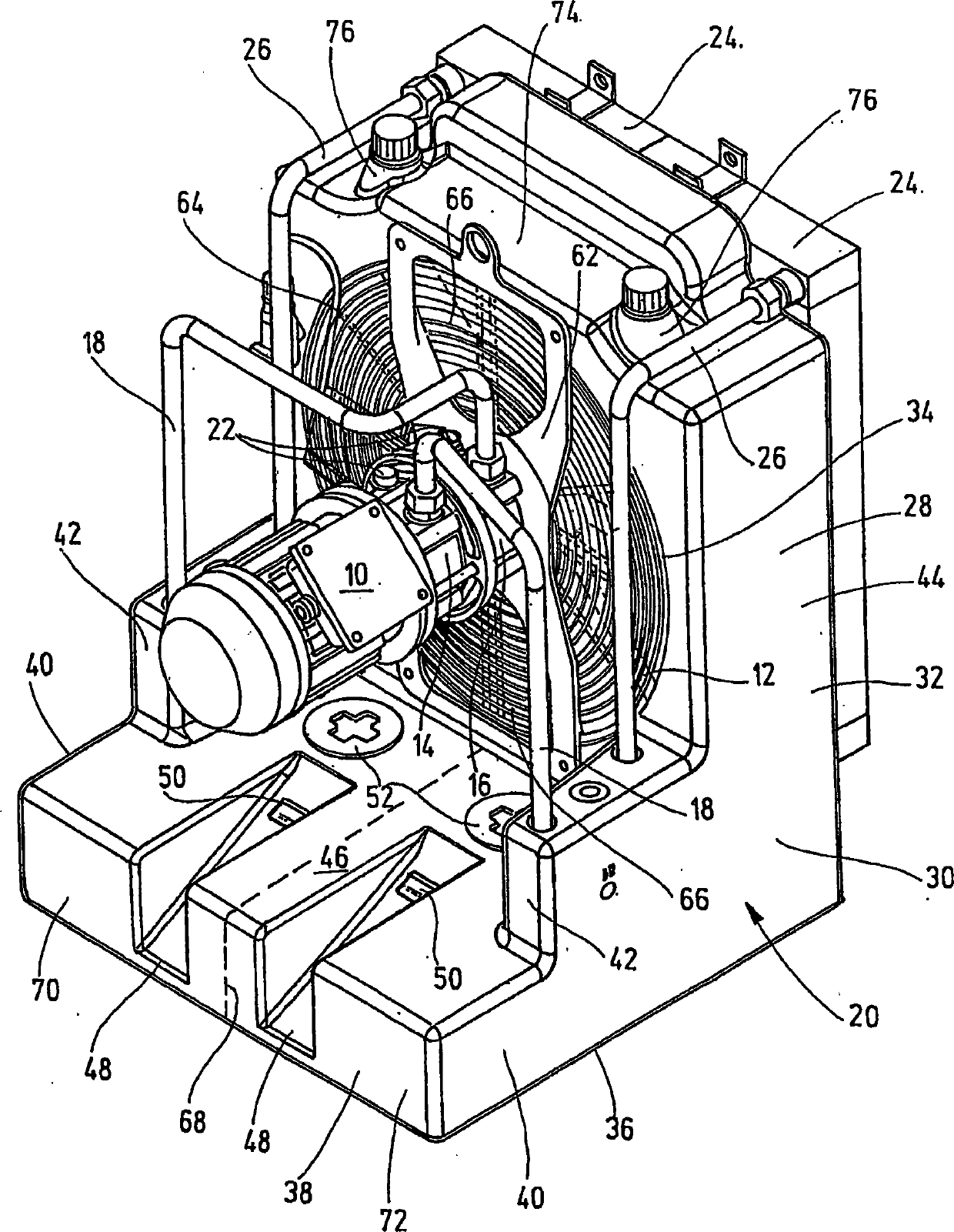

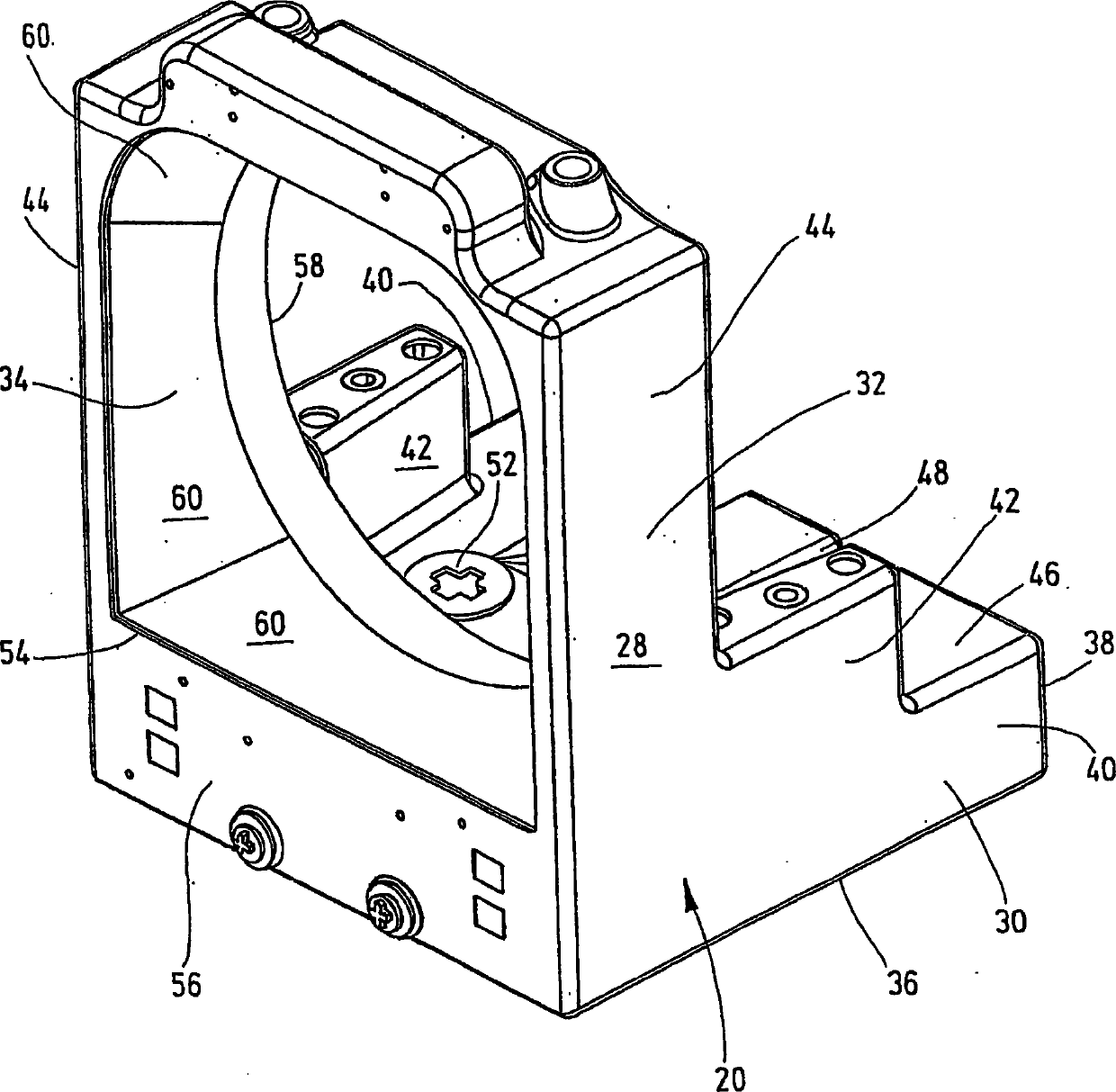

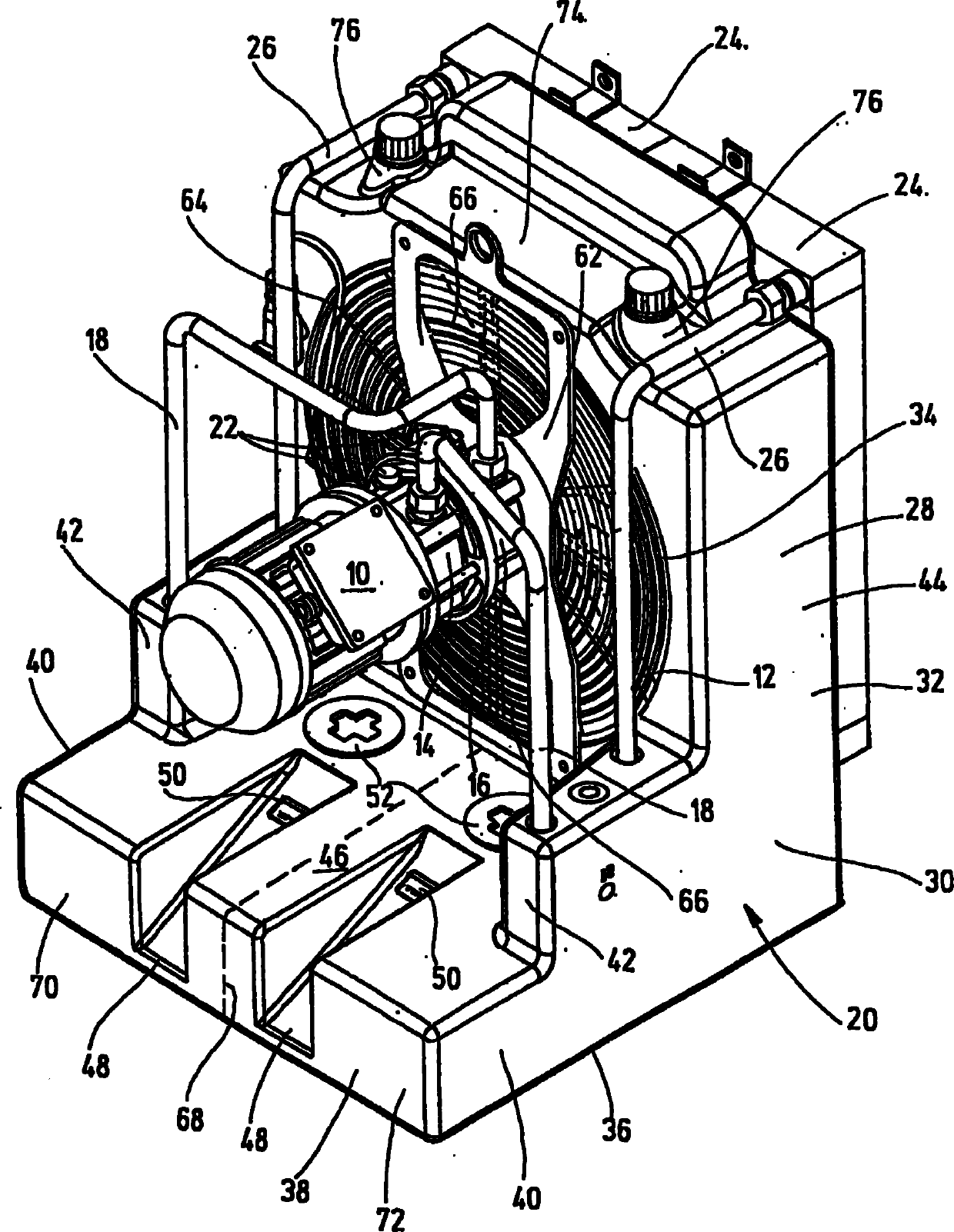

[0015] figure 1 The fluid cooling device of the present invention shown as a whole in , is designed as a modular component and can be sold as such. especially by figure 1 The fluid cooling device can be integrated into the existing hydraulic circuit of the engine or machine tool in order to achieve fluid cooling of the operating medium, for example in the form of hydraulic oil. according to figure 1 The view of the shows the normal installation position of the fluid cooling device, in which it can be installed vertically on a part of the workshop floor etc., but which can also be fixed to the machine and plant via a free side surface of the machine and plant part partly on.

[0016] The fluid cooling device has a general-purpose electric motor 10 , which drives a fan wheel 12 with individual fan wheel blades and two fluid pumps 14 , 16 . Each fluid pump 14 , 16 draws an assignable fluid, for example in the form of hydraulic oil, water-glycol, etc., from a reservoir general...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com