Method for cultivating spirulina

A technology for spirulina and aquaculture tanks, applied in the direction of unicellular algae, etc., can solve the problems of difficult to guarantee product quality, change influence, easy to be affected by the environment and seasons, etc. susceptible to contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

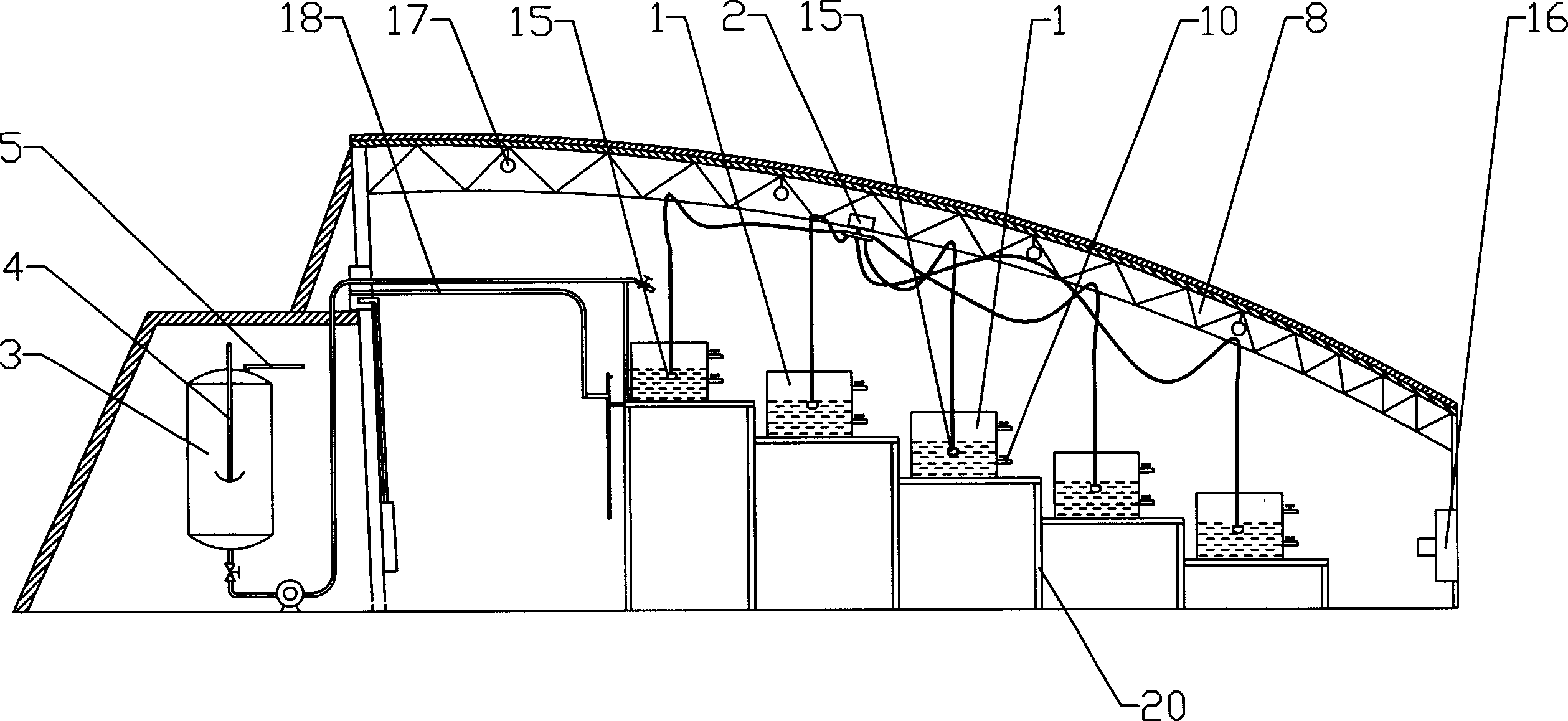

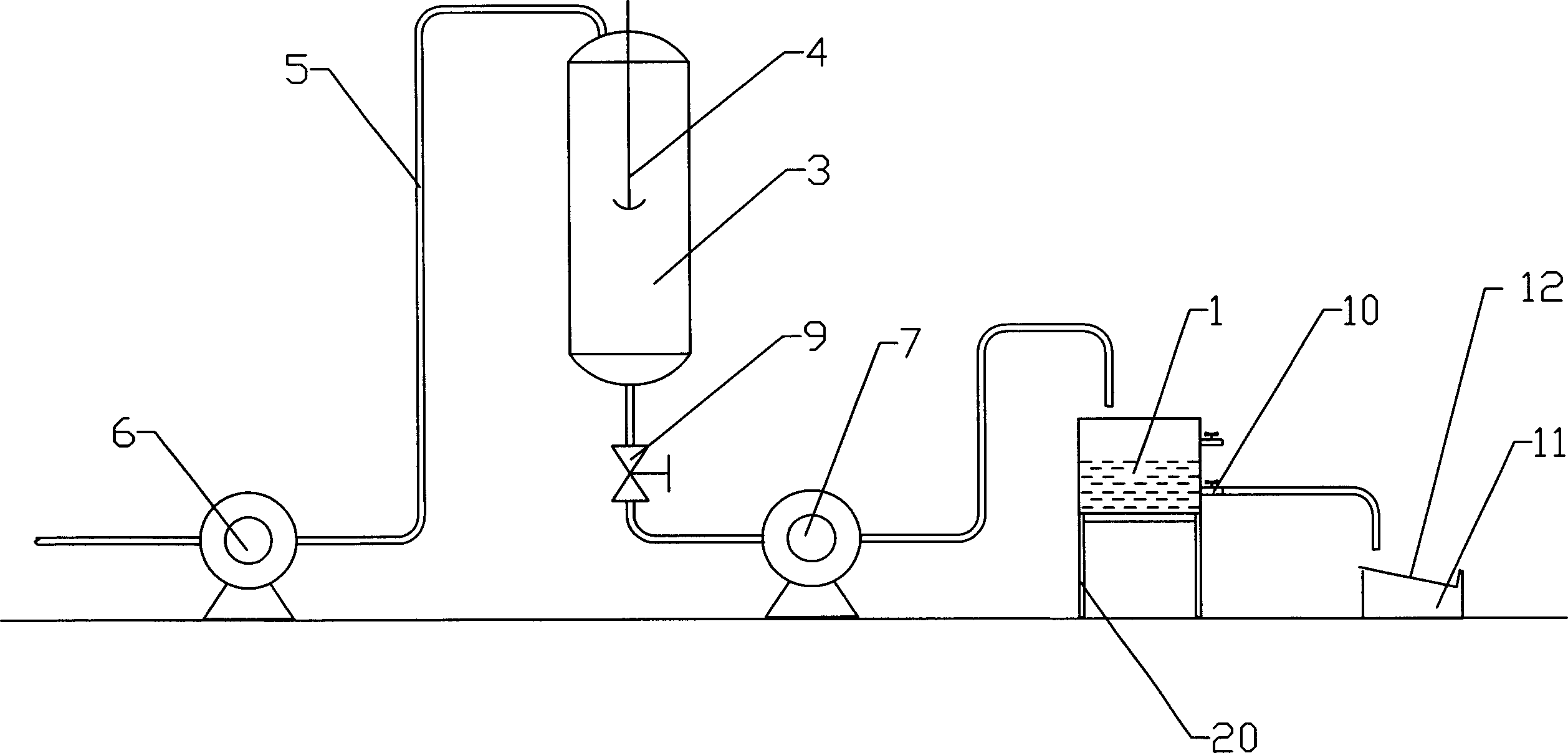

[0031] Embodiment 1, as attached figure 1 , 2 Shown is a method for cultivating spirulina. This method includes building a culture environment for spirulina, dosing, nursing during cultivation, and collecting, harvesting and preserving spirulina. First, choose a place with sufficient sunlight to build a greenhouse 8 , the greenhouse 8 is provided with a stepped support 20, the glass cultivation tank 1 for cultivating spirulina is placed on the top of the stepped support 20, the glass cultivation tank 1 is provided with an aeration device, and the aeration device is included in the glass cultivation tank 1 The aerator head 15 for the fish tank and the electromagnetic air pump 2 gas-communicated with the aerator head 15 for the fish tank, the electromagnetic air pump 2 has an air filtering device, and the east, west and north sides of the greenhouse 8 are provided with support on the wall For radiator fins, an induced draft fan 16 is installed at the front of the greenhouse 8 f...

Embodiment 2

[0032] Embodiment 2, as attached figure 1 , 2 Shown is a method for cultivating spirulina. This method includes building a culture environment for spirulina, dosing, nursing during cultivation, and collecting, harvesting and preserving spirulina. First, choose a place with sufficient sunlight to build a greenhouse 8 , the greenhouse 8 is provided with a stepped support 20, the glass cultivation tank 1 for cultivating spirulina is placed on the top of the stepped support 20, the glass cultivation tank 1 is provided with an aeration device, and the aeration device is included in the glass cultivation tank 1 The aerator head 15 for the fish tank and the electromagnetic air pump 2 gas-communicated with the aerator head 15 for the fish tank, the electromagnetic air pump 2 has an air filtering device, and the east, west and north sides of the greenhouse 8 are provided with support on the wall For radiator fins, an induced draft fan 16 is installed at the front of the greenhouse 8 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com