Construction method for vibrated asphalt concrete anti-infiltration core wall of earth rockfill dam

A technology of asphalt concrete and construction method, applied in the direction of dams, sheet pile walls, barrages, etc., can solve the problems of poor overall stability and anti-seepage effect, expensive equipment, strict environmental temperature requirements of asphalt concrete, etc., and achieve simple construction equipment Easy to implement, simple in structure, easy to popularize and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Include the following steps:

[0083] a. Laying formwork:

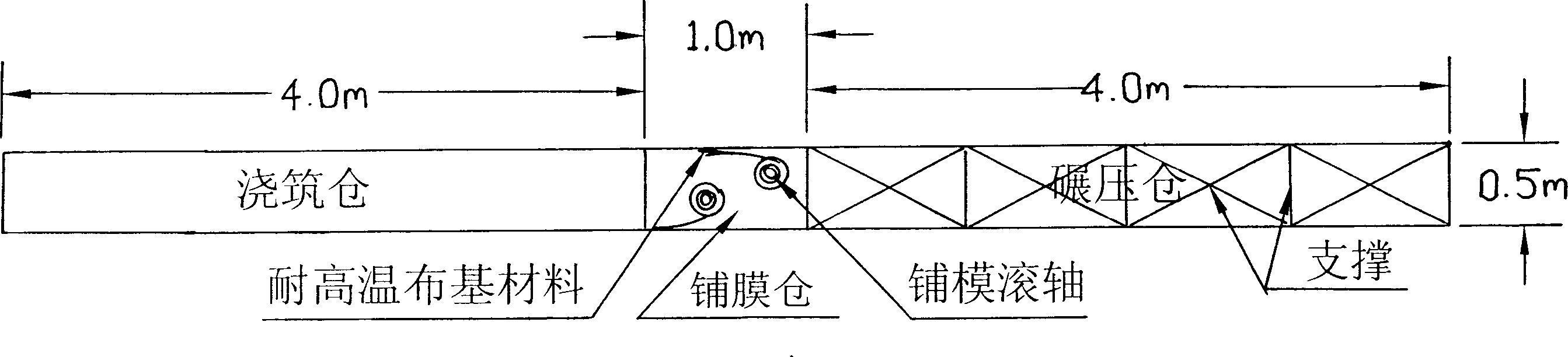

[0084] During construction, the asphalt concrete formwork is laid vertically on the base of the core wall, so that the centerline of the formwork and the centerline of the core wall completely coincide; the sliding formwork structure is adopted; the sliding formwork warehouse is divided into three parts: rolling warehouse, film-laying warehouse and pouring warehouse. Among them, the length of the rolling bin is 4m, the length of the film-laying bin is 1m, the length of the pouring bin is 4m, the height of the formwork bin is 35cm, and the width of the formwork is determined to be 150cm according to the width of the core wall base. The sliding formwork bin is pulled by hoist or other traction equipment. The formwork is made of 10mm steel plate. A certain number of supports are welded inside the rolling bin. The film-laying bin is equipped with a film-laying shaft, and a reverse baffle is set between the film-lay...

Embodiment 2

[0098] a. Laying formwork:

[0099] During construction, the asphalt concrete formwork is laid vertically on the core wall, so that the centerline of the formwork and the centerline of the core wall completely coincide; the assembled movable formwork is adopted, the length of the steel plate is 4m, and the supporting frame is movable in the middle, and the width of the two steel plates is 100cm.

[0100] b. Lay non-woven fabric:

[0101] After the formwork is laid, a 200°C high-temperature resistant non-woven fabric is laid close to the inside of the formwork, and the width is 8cm higher than the height of the formwork;

[0102] c. Paving transition material and rolling of transition material:

[0103] Pave the common transition material for the dam on the outside of the formwork, and roll it until the compactness meets the design requirements of the dam; at the same time

[0104] Embodiment 1;

[0105] d. Paving asphalt concrete:

[0106] Pour the vibrated asphalt mixture...

Embodiment 3

[0116] a. laying formwork: with embodiment 1

[0117] b. Lay non-woven fabric:

[0118] After the template is laid, lay a high-temperature resistant non-woven fabric close to the inside of the template. The non-woven fabric can withstand high temperatures of 250°C and the width is 10cm higher than the height of the template;

[0119] c. paving transition material and transition material rolling: same as embodiment 1

[0120] d. Paving asphalt concrete:

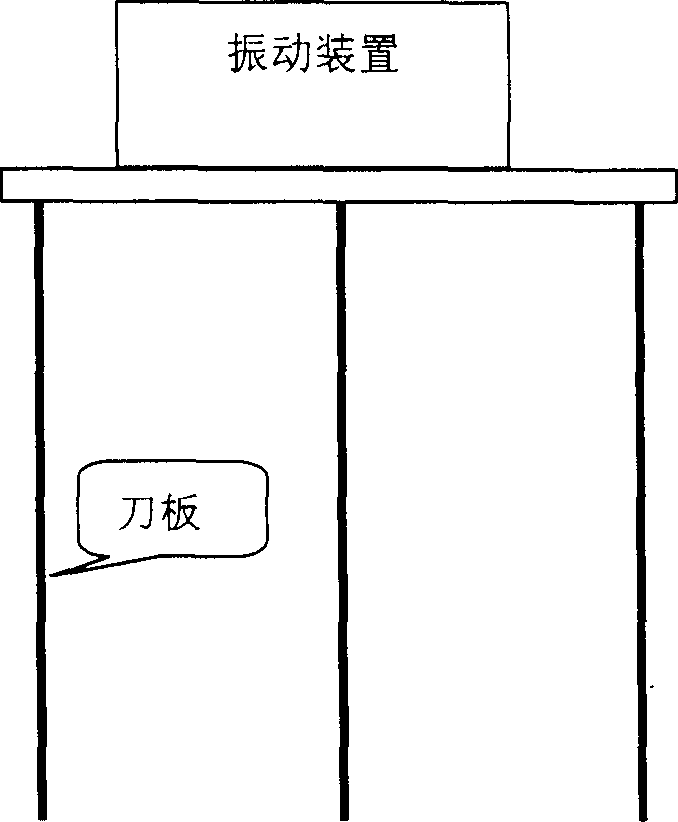

[0121] Pour the vibrated asphalt mixture into the formwork and use a knife plate vibrator to vibrate it compactly. The raw materials of the vibrated asphalt mixture include: parts by weight:

[0122]Aggregate and slag powder, 100 parts, the performance of the aggregate and slag powder should meet the requirements of the "Design Criteria for Asphalt Concrete Face and Core Wall of Earth-rock Dam" (SLJ01-88), of which 85% are aggregate, the maximum particle size is 20mm, and the rest are Mineral powder;

[0123] Asphalt, asph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com