Method and apparatus for converting conservative internal force into non-conservative internal force

An internal force, conservative technique applied to mechanisms, engines, machines/engines, etc. that generate mechanical power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

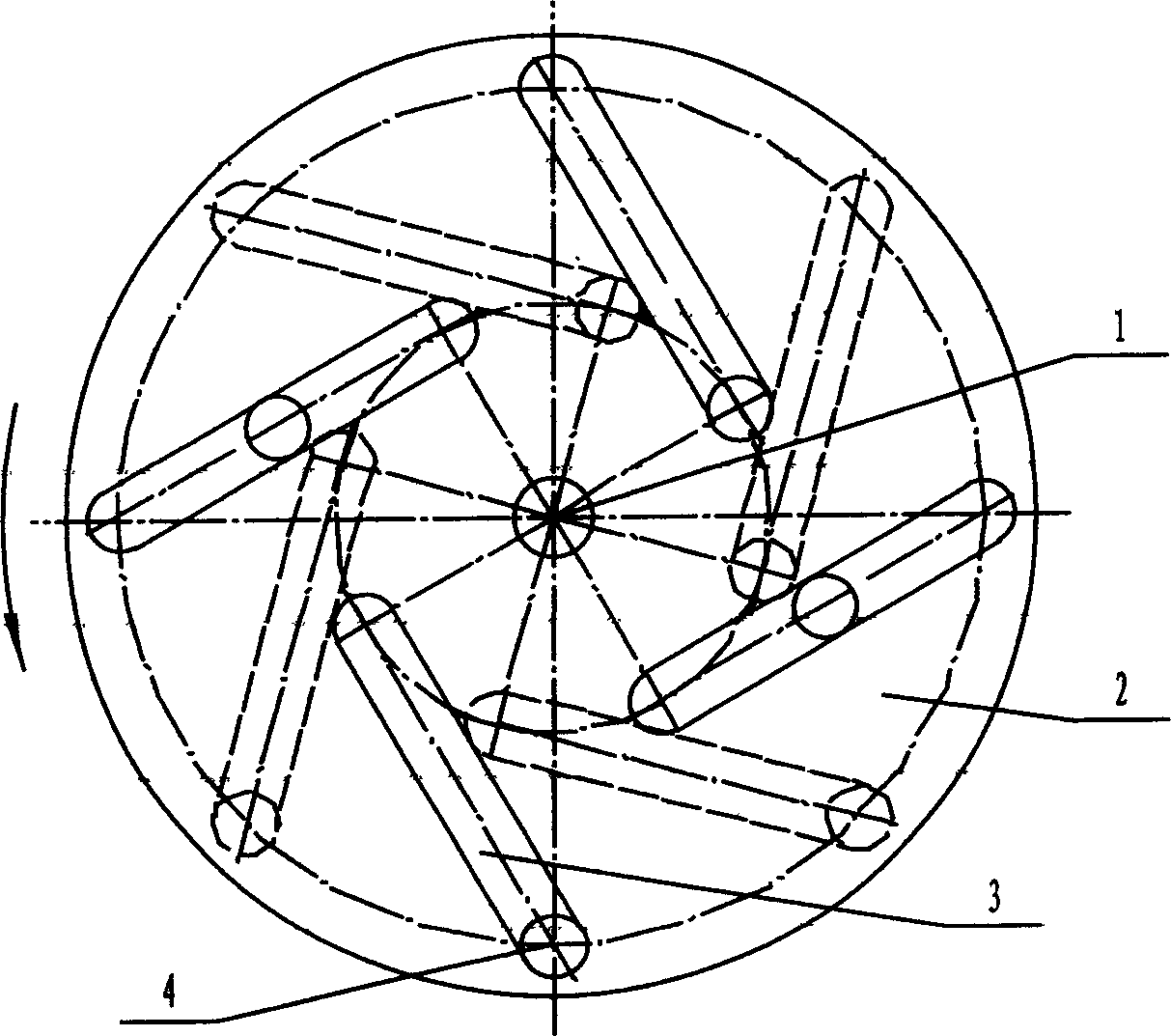

[0033] The diameter of the disc-shaped body is 3000 mm, and there are 8 grooves arranged alternately on the front and back sides, evenly distributed, and inclined at 30°, of which 4 are on each side. In order to reduce the moment of inertia of the disc-shaped body, it adopts an aluminum alloy frame structure; Body is cylinder, total number n=8, adopts steel, and diameter is 200 millimeters, and length is 280 millimeters, and the quality m=69kg of cylinder; The diameter of the circle where the inner end of the groove is located is 2r=1340 mm; the structural form is as image 3 shown.

Embodiment 2

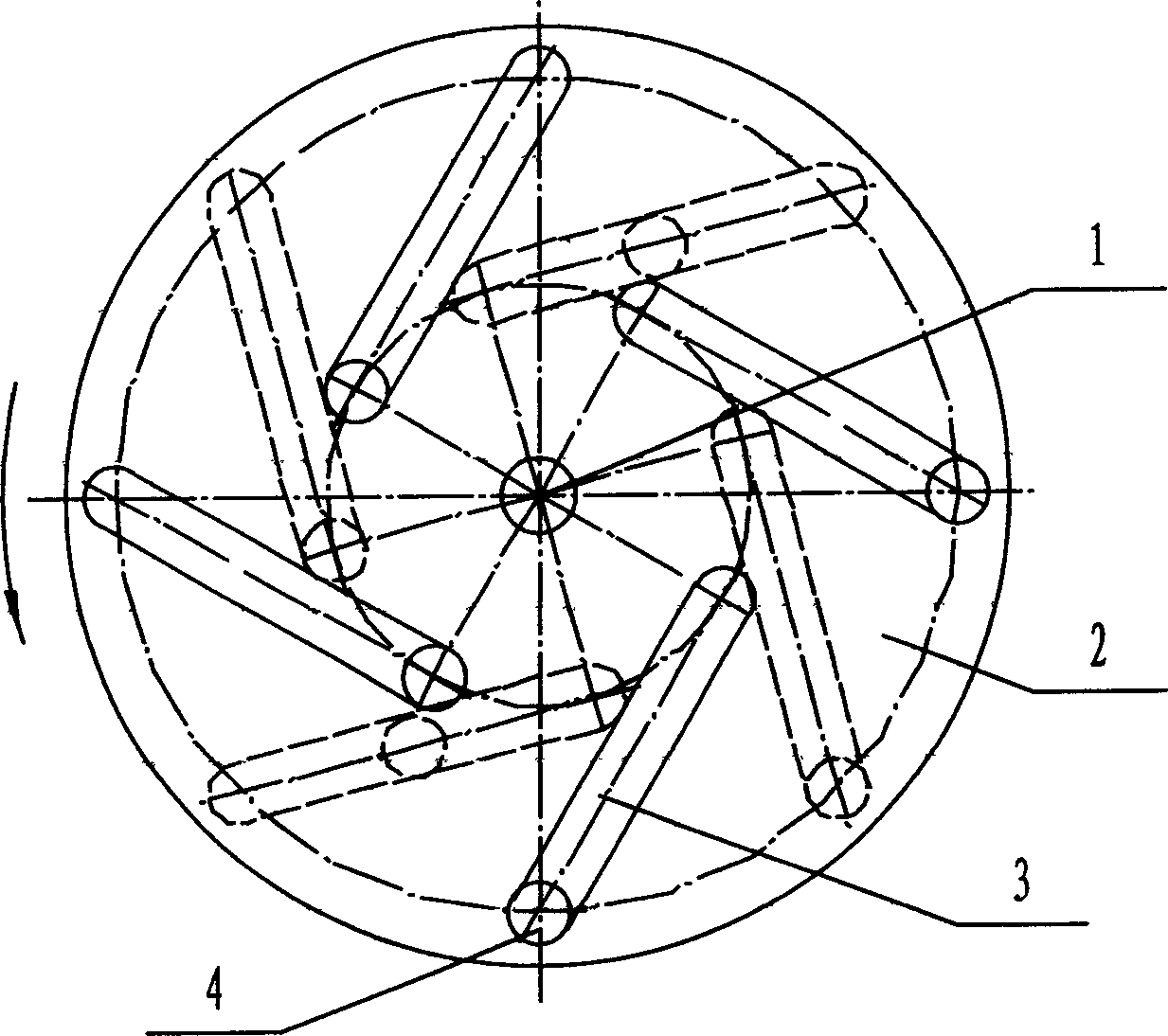

[0035] The diameter of the disc-shaped body is 9500 mm, and there are 8 grooves arranged alternately on the front and back sides, evenly distributed, and inclined at 45°, of which 4 are on each side. In order to reduce the moment of inertia of the disc-shaped body, it adopts a steel frame structure; The total number of spheres is n=8, made of steel, with a diameter of 600 mm, and the mass of rolling spheres is m=887.8kg; the diameter of the circle where the sphere is located at the outer end of the groove is 2R=8202 mm, and the diameter of the circle where the sphere is located at the inner end of the groove is 2r=5800 mm; structural form such as image 3 shown.

Embodiment 3

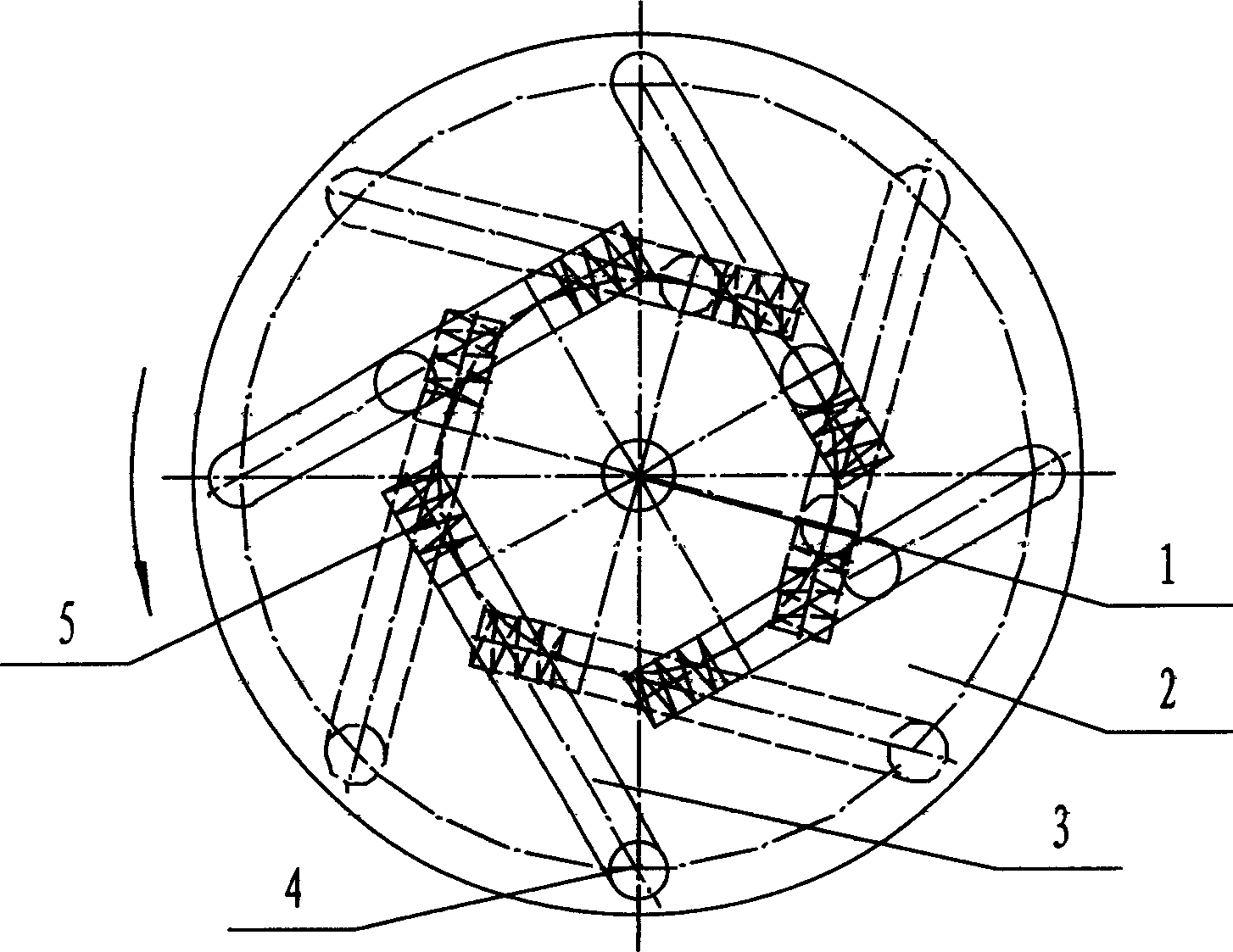

[0037] The diameter of the disc-shaped body is 9500 mm, and there are 12 grooves arranged alternately on the front and back sides, evenly distributed, and inclined at 30°, of which 6 are on each side. In order to reduce the moment of inertia of the disc-shaped body, it adopts a steel frame structure; Body is cylinder, total number n=12, adopts steel, and diameter is 600 millimeters, and length is 720 millimeters, and the quality m=1598kg of cylinder; The diameter of the circle where the inner end of the groove is located is 2r=4100 mm; the structural form is as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com