Terminal and its electro-plating method

A terminal and plating technology, applied in the field of terminals and their electroplating, can solve the problems of not ensuring the wear resistance and corrosion resistance of the contact parts of the terminals, and achieve the guarantee of service life, good electrical conductivity, and improved corrosion resistance and wear resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

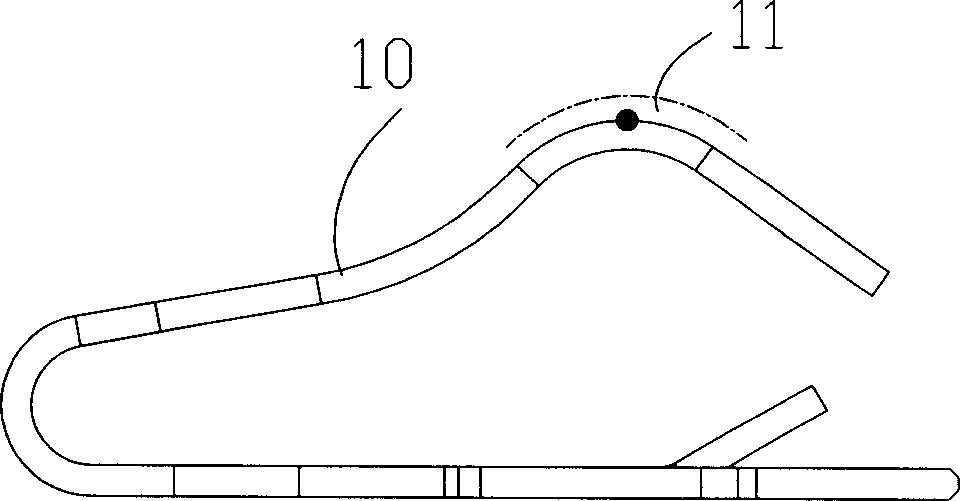

[0011] see figure 1 and figure 2 , the electrical connector terminal 10 of the present invention is mainly used in a plug-in type electrical connector, wherein the contact area 11 of the terminal 10 is often plugged and contacted with other electronic components (not shown), so the contact area 11 needs good corrosion resistance and abrasion resistance.

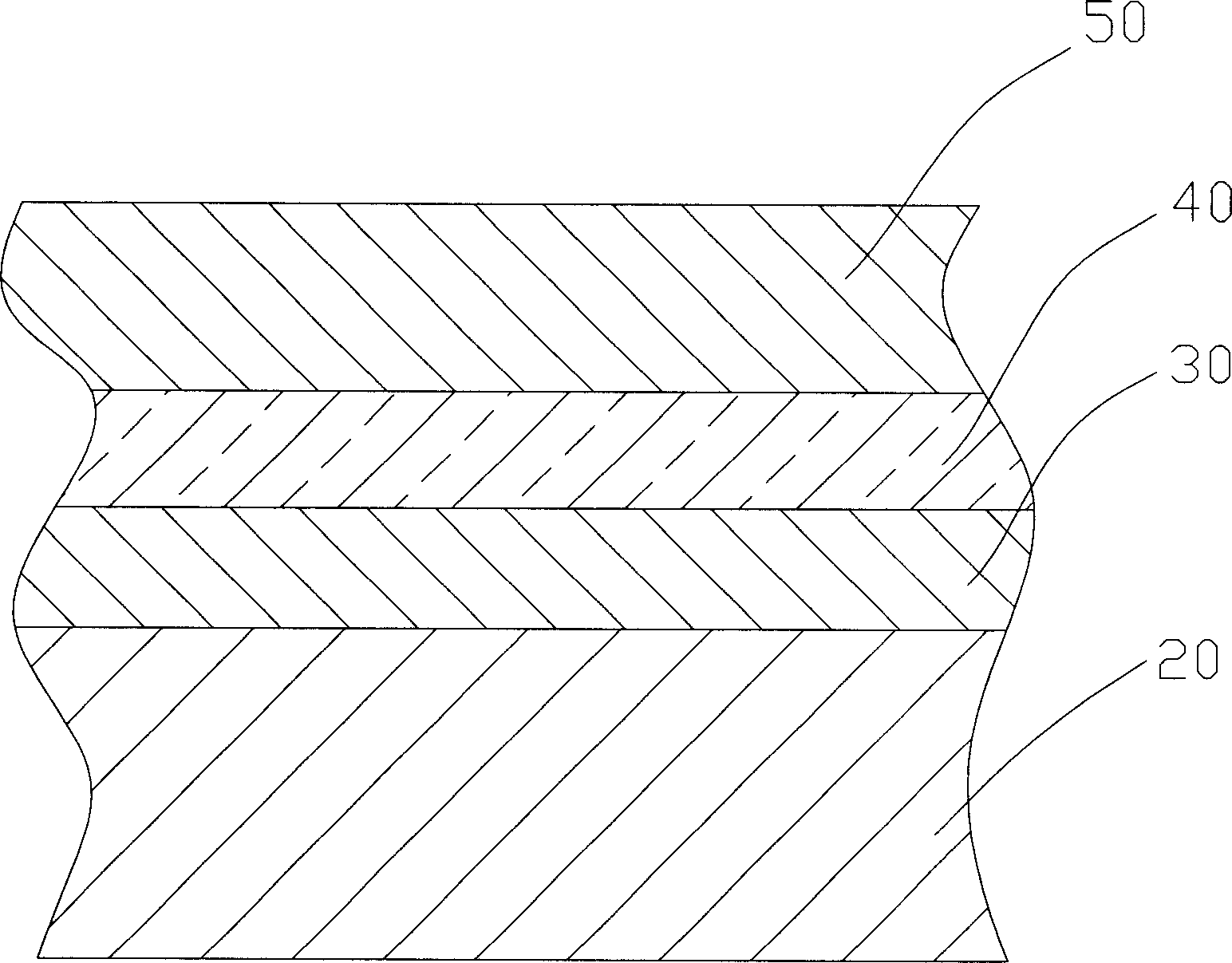

[0012] Usually, in order to enhance the corrosion resistance, wear resistance and conductivity of the terminal 10, one or more layers of metal need to be plated on the terminal 10, and the base material 20 of the contact area 11 of the terminal 10 is generally bronze or phosphor copper, and can also be For other copper alloys or other alloys, in order to reduce the contact resistance of the terminal, enhance corrosion resistance and sliding properties, before the gold plating layer 40 is plated, the first nickel plating layer 30 is plated on the entire surface of the terminal 10 to prevent the terminal 10 from being damaged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com