Size variable touch system based on pattern recognition

An image recognition and variable technology, applied in the input/output process of data processing, instruments, electrical and digital data processing, etc., can solve the problems of cumbersome, large-scale resistive screen, easy to be exposed to sunlight, etc., to simplify the hardware circuit , convenient design and application, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

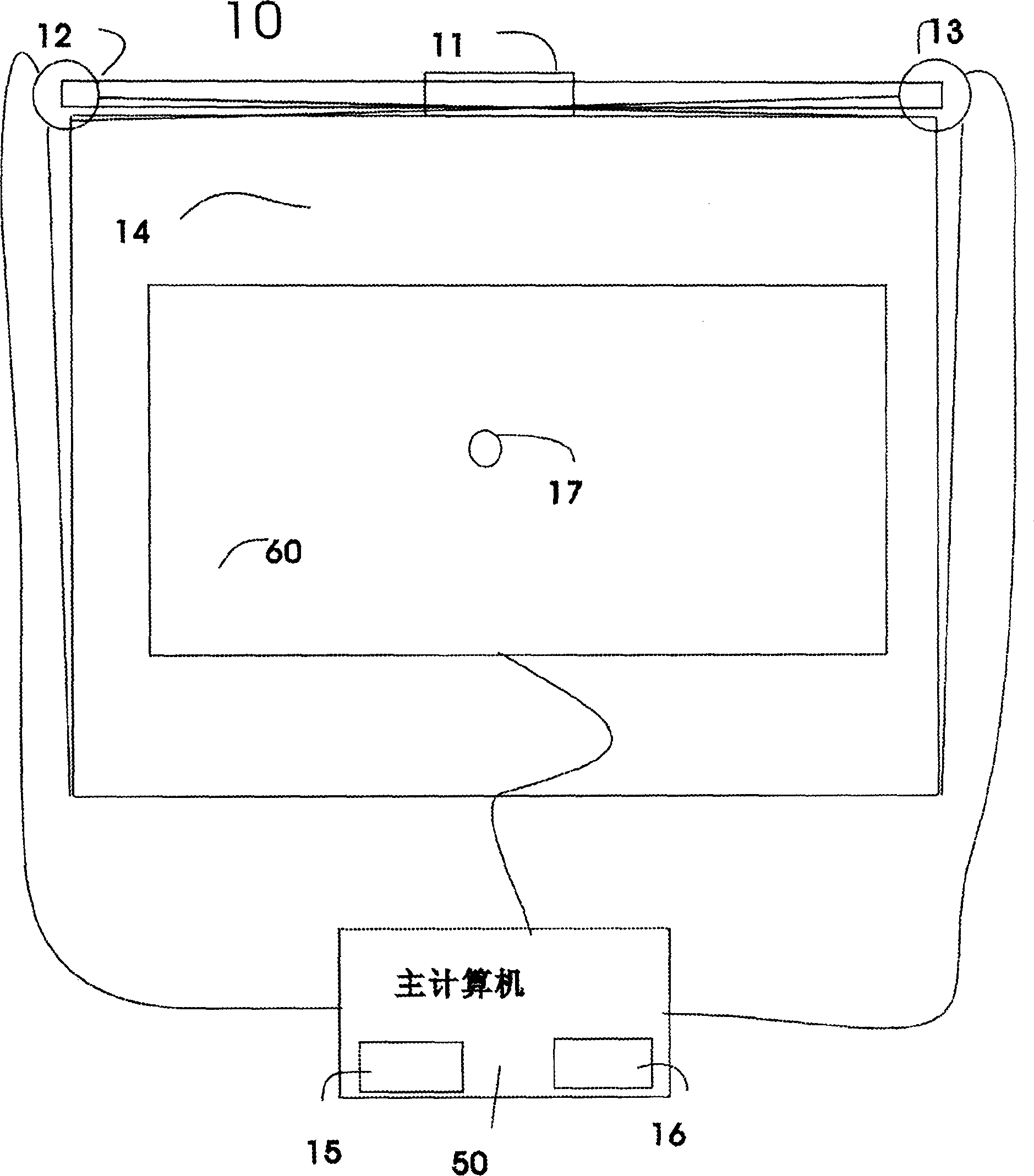

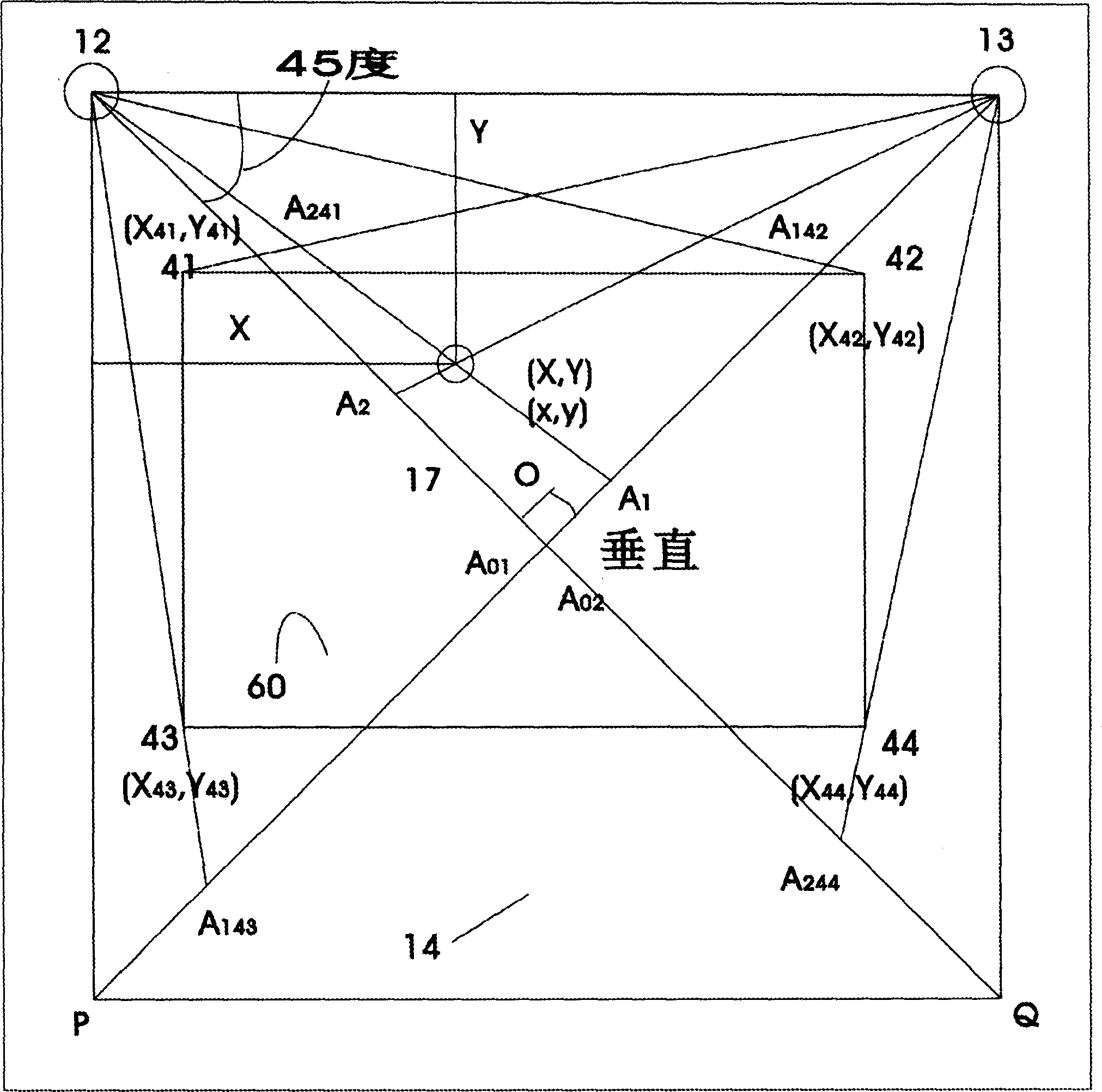

[0025] attached figure 1 The variable-size touch system based on image recognition of the present invention is shown, which is indicated by reference numeral 10 in the drawings. As shown in the figure, the touch system 10 includes a rod body 11 of variable length, two cameras 12, 13 are installed at both ends of the rod body, and the cameras are respectively connected to a computer 50 through a high-speed serial data bus such as USB or 1394. , install and run the driver program 15 for image recognition and position calculation included in the touch system 10 and the corresponding auxiliary program 16; the viewing areas of the cameras 12 and 13 overlap each other to form a rectangular section with the two cameras as adjacent vertices 14, the interval 14 covers the display interval of the display device 60; generally, the display interval of the display device 60 is the touch interval for the user to operate; When operating in the display section, the computer will hand over th...

Embodiment 2

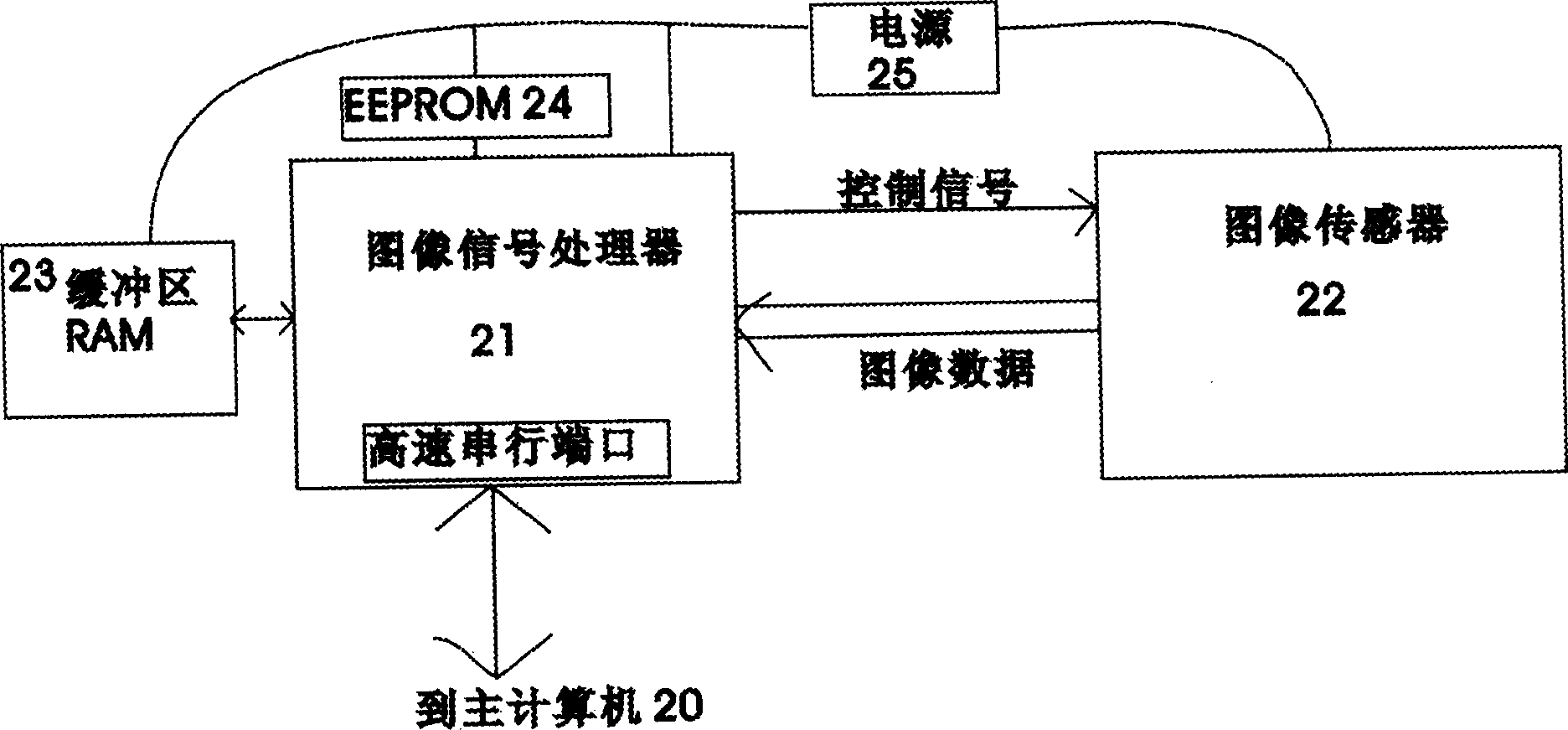

[0054] This embodiment is identical with embodiment 1 on hardware structure, and difference is that the image recognition function in the driver program 15 among the embodiment 1 is to finish in the image signal processor 21 of respective video camera, and video camera passes to host computer 50 It is not image data, but the position coordinates of the recognized pointer in the pixel sequence, and then the driver 15 completes the relevant coordinate transformation and calculation of relative coordinates, and calculates the coordinate information of the pointer 17 in the touch interval 60 for the computer 50 operating systems are used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com