Ferroelectric memory device and manufacturing method thereof

A manufacturing method and memory technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, circuits, etc., can solve the problems of losing ferroelectric effect and achieve fast response speed, eliminate fatigue phenomenon, and good ferroelectric effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

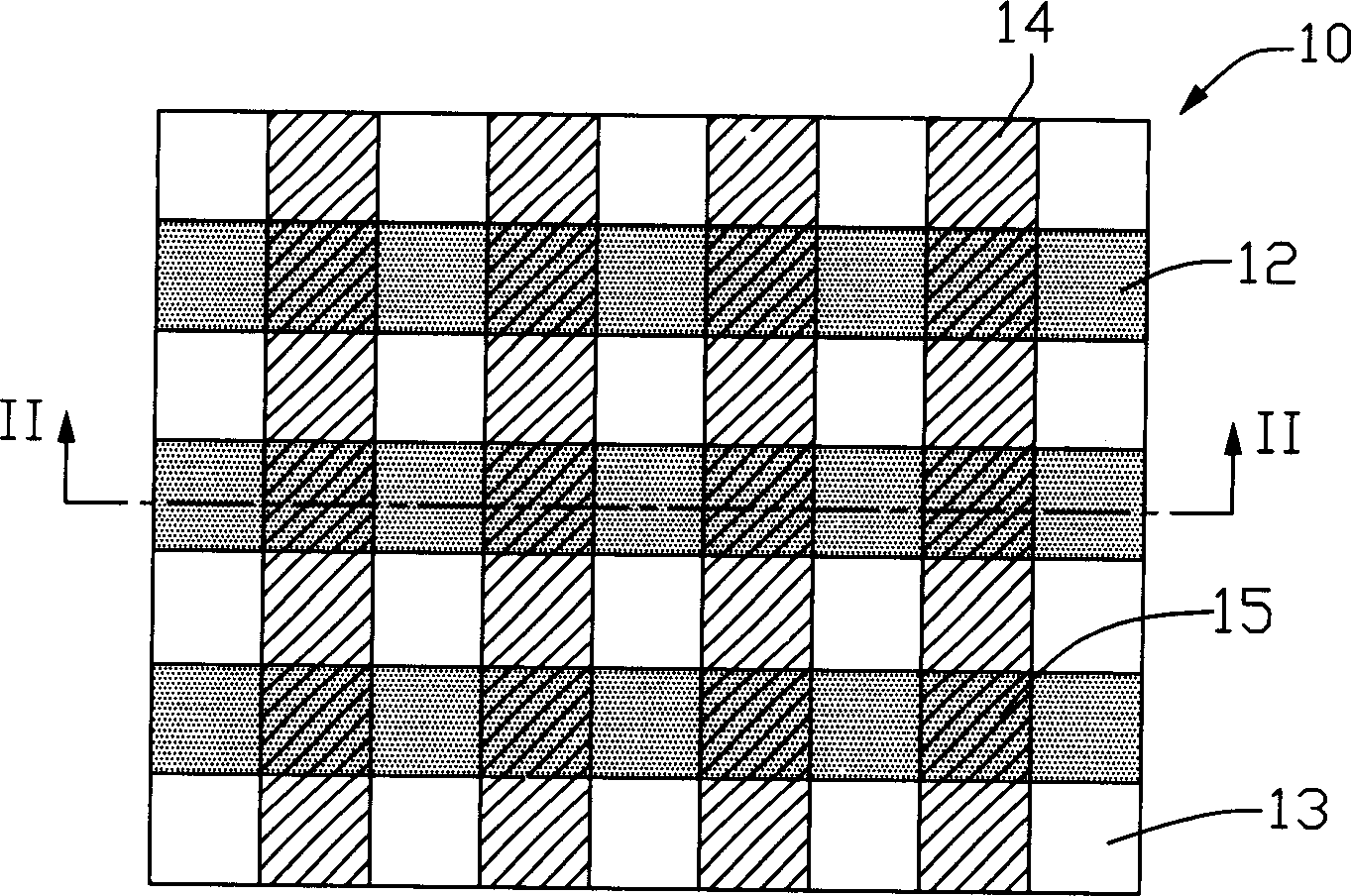

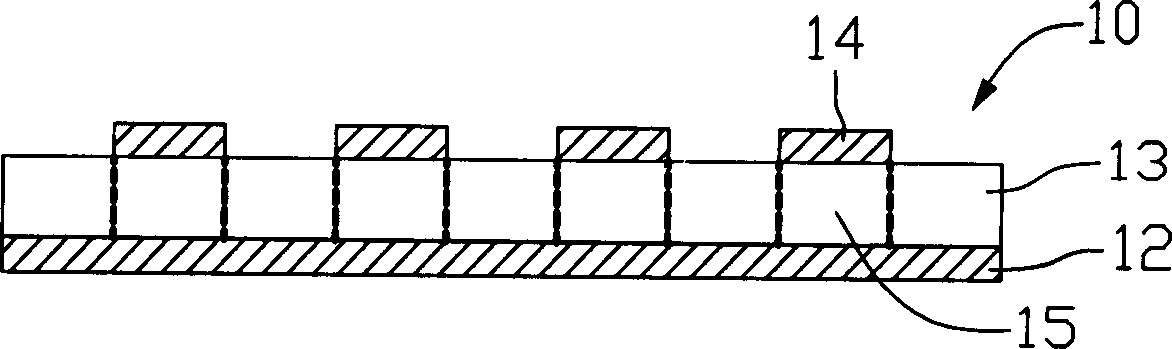

[0019] see figure 1 , the present invention provides a ferroelectric memory device 10, which includes: a plurality of first electrodes 12, the first electrodes 12 are substantially parallel to each other, forming word lines of the ferroelectric memory device 10. A plurality of second electrodes 14 , which are substantially parallel to each other and arranged in a cross-vertical direction with the above-mentioned first electrodes 12 , form bit lines of the ferroelectric memory device 10 . The ferroelectric memory film 13 is located between the first electrode 12 and the second electrode 14 to form a plurality of storage units 15 of the ferroelectric memory device 10 . The material of the ferroelectric memory thin film 13 is a ferroelectric polymer. The ferroelectric polymer is formed by mixing ferroelectric nano crystals with a polymer matri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com