Transistor level shift circuit

A technology of level shift circuits and transistors, which is applied in the fields of logic circuit coupling/interface, logic circuit connection/interface arrangement, and instruments using field effect transistors, which can solve the problems of inability to integrate, complex circuit structure and connection method, and high production cost. problem, to achieve the effect of improving the operation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

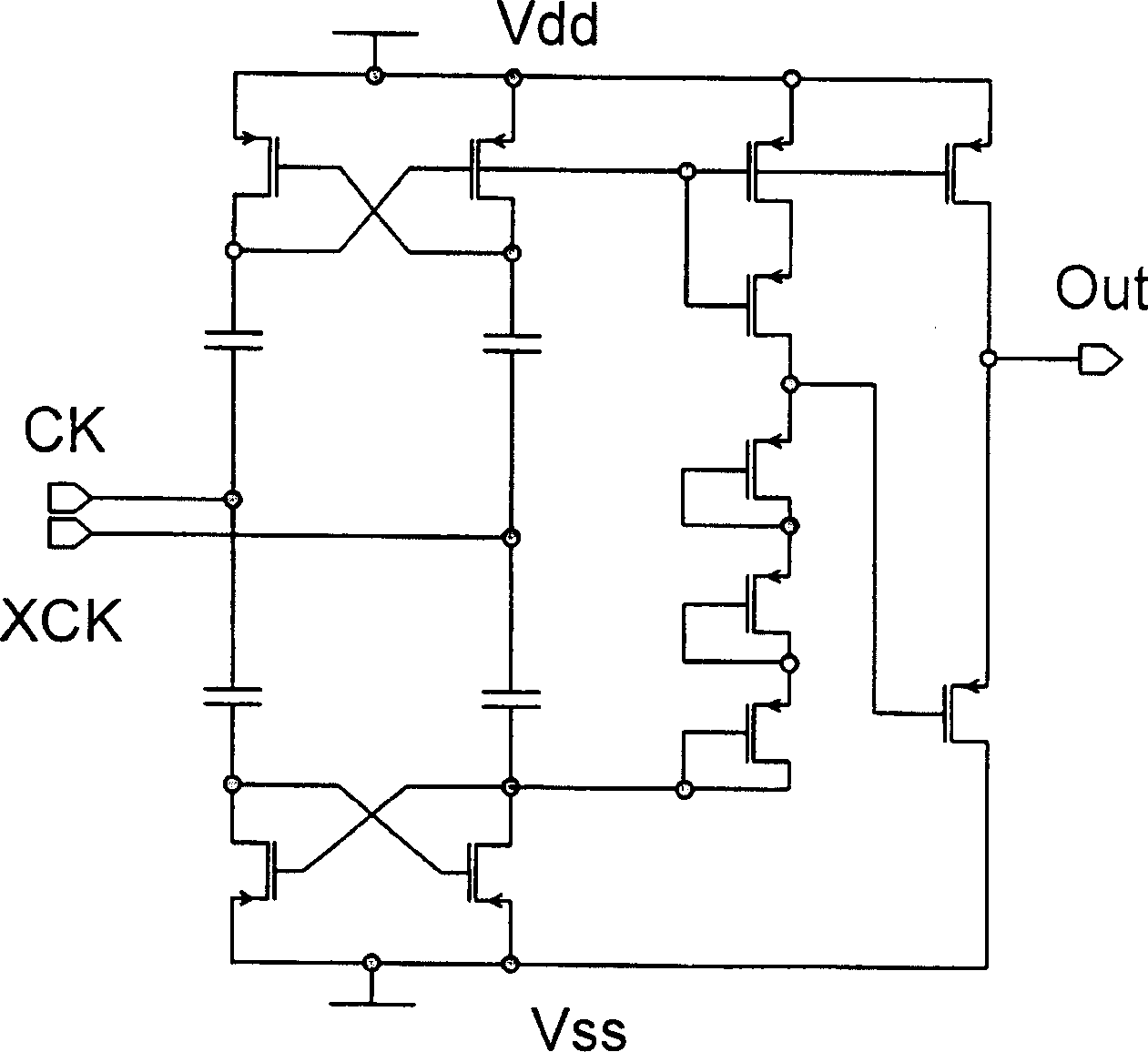

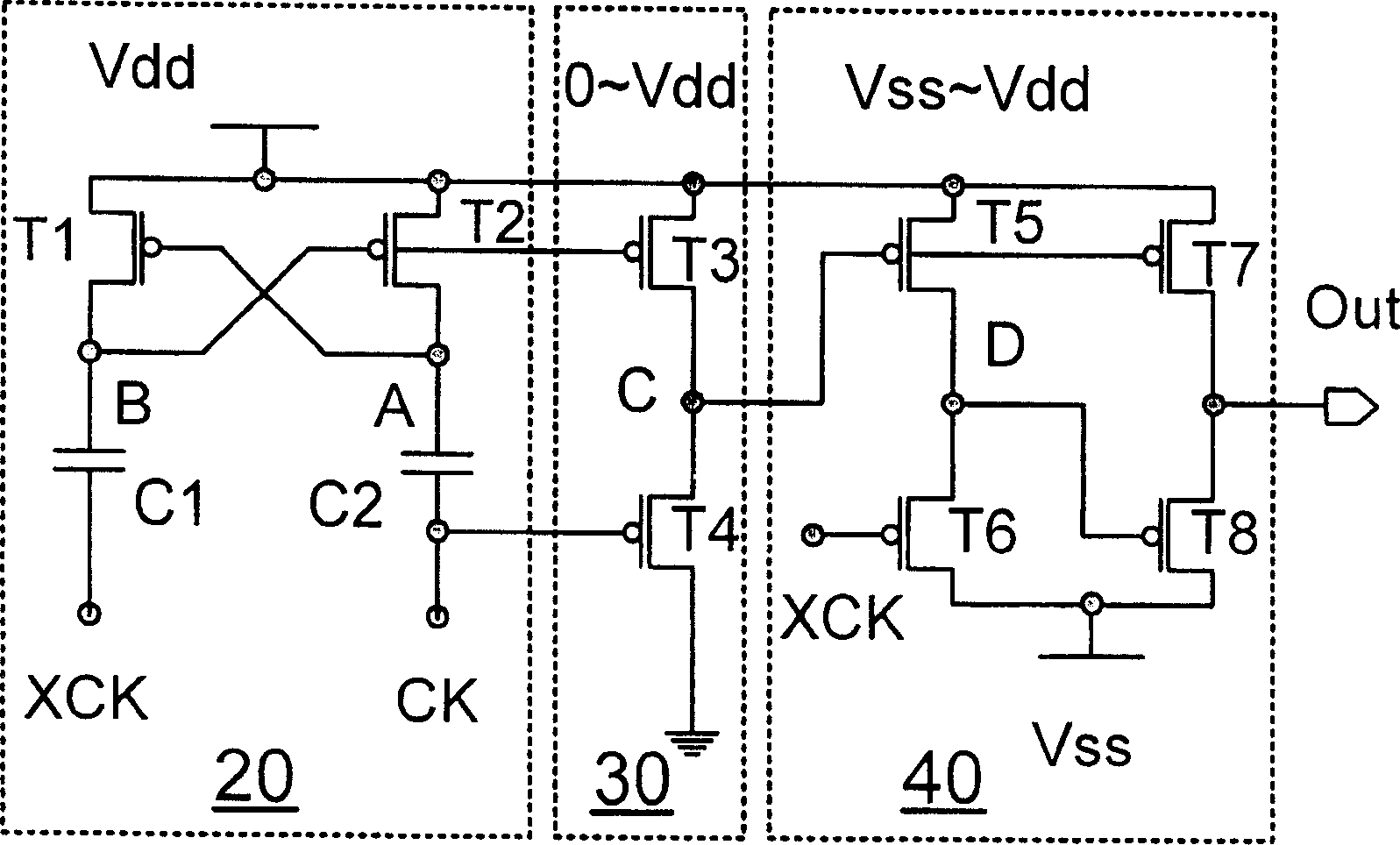

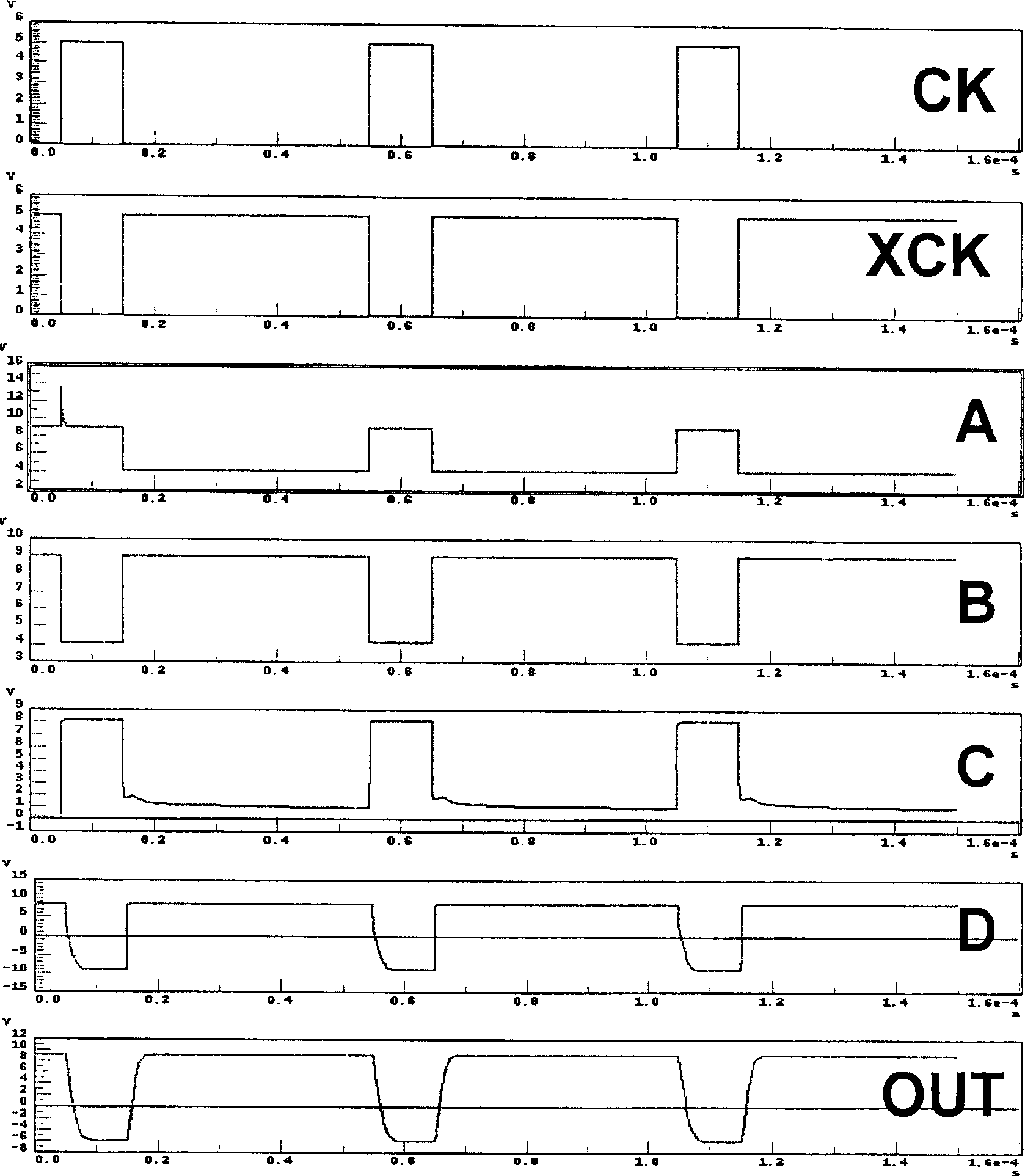

[0021] like Figure 2A Shown is a circuit diagram of a transistor level shift circuit in a preferred embodiment of the present invention, the transistor level shift circuit is suitable for use between a first power supply and a second power supply, the voltage level of the first power supply is greater than the The voltage level of the second power supply, the level shift circuit is used to amplify the voltage level of a first complementary pair of signals, the first complementary pair of signals includes a clock signal and an inverted clock signal, the transistor level shift circuit It includes a conversion circuit 20, a first amplification circuit 30 and a second amplification circuit 40, wherein the conversion circuit 20 is used to generate a second complementary pair signal after receiving the first complementary pair signal, and the second complementary pair signal The voltage level is substantially between the voltage level of the first power supply and the difference be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com