Method for prepurifying air in an accelerated tsa cycle

An air and pre-purification technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of unobtainable gas flow, reduction of effective heat ratio, increase of system thermal inertia and dead volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

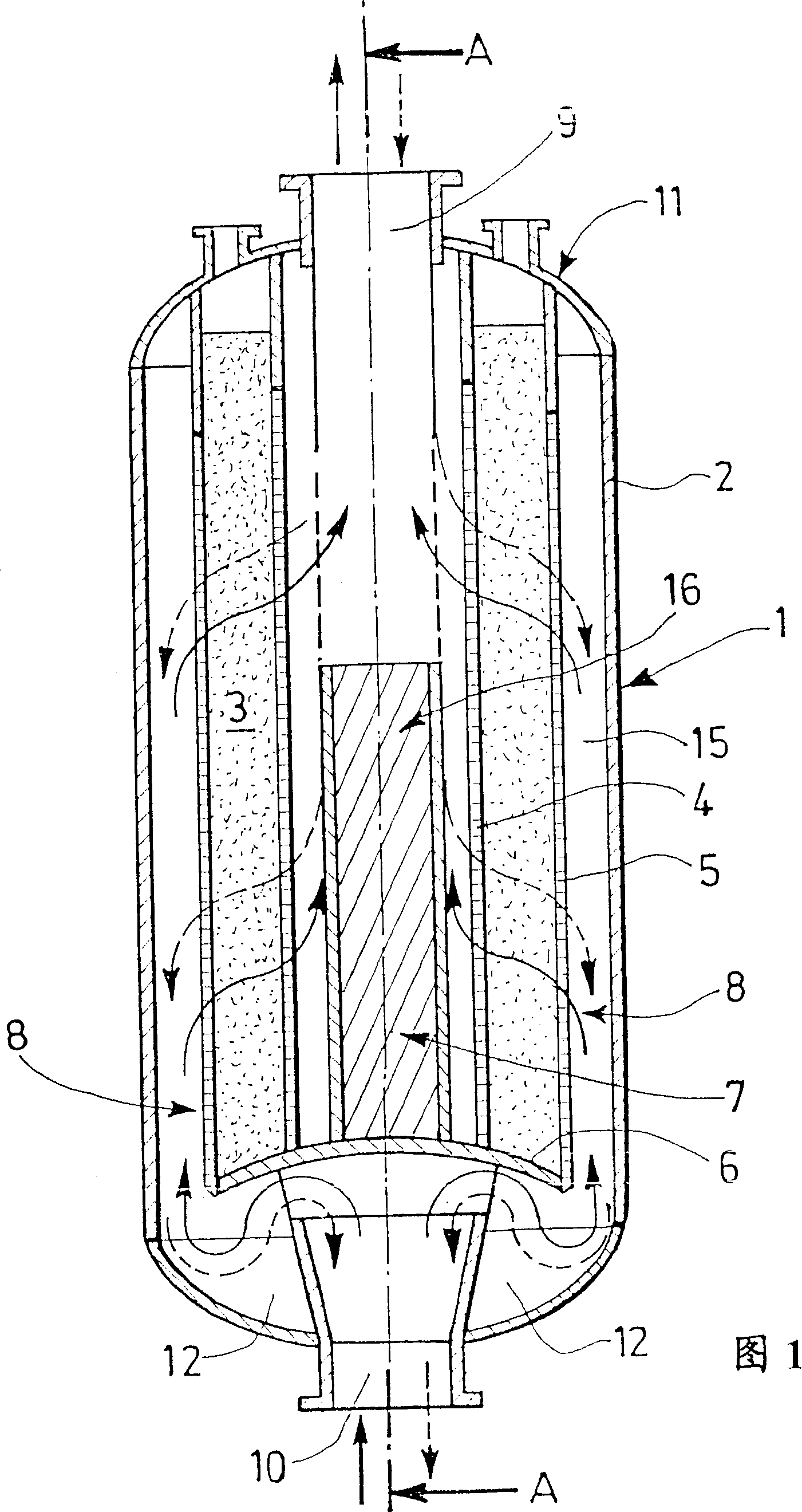

[0086] According to the invention, the reduction of thermal inertia is achieved by using one or more adsorbers 1 of the radial type, as shown in the accompanying drawing 1, which shows the adsorption along the axis A-A of an adsorber 1 applicable in the context of the present invention. Cross-section, wherein in the radial adsorber 1, the regeneration gas flows in the centrifugal direction, that is, flows from the center of the adsorber 1 to the periphery, and on the contrary, the gas to be purified flows in the centripetal direction, that is, flows from the adsorption The periphery of device 1 flows toward its center.

[0087] More precisely, air purified under a certain pressure is introduced to the side of the circumferential outer wall 2 of the adsorber 1 via a first orifice 10 located at the end 12 of the adsorber 1, wherein the adsorber contains The adsorbent in 3, the adsorbent bed 3 has a cylindrical three-dimensional shape with a hollow volume 16, that is to say, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com