Electronic components packaging substrate

A technology for the installation of electronic components and electronic components, which is applied in the directions of printed circuit components, assembling printed circuits with electrical components, and electrically connecting printed components. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

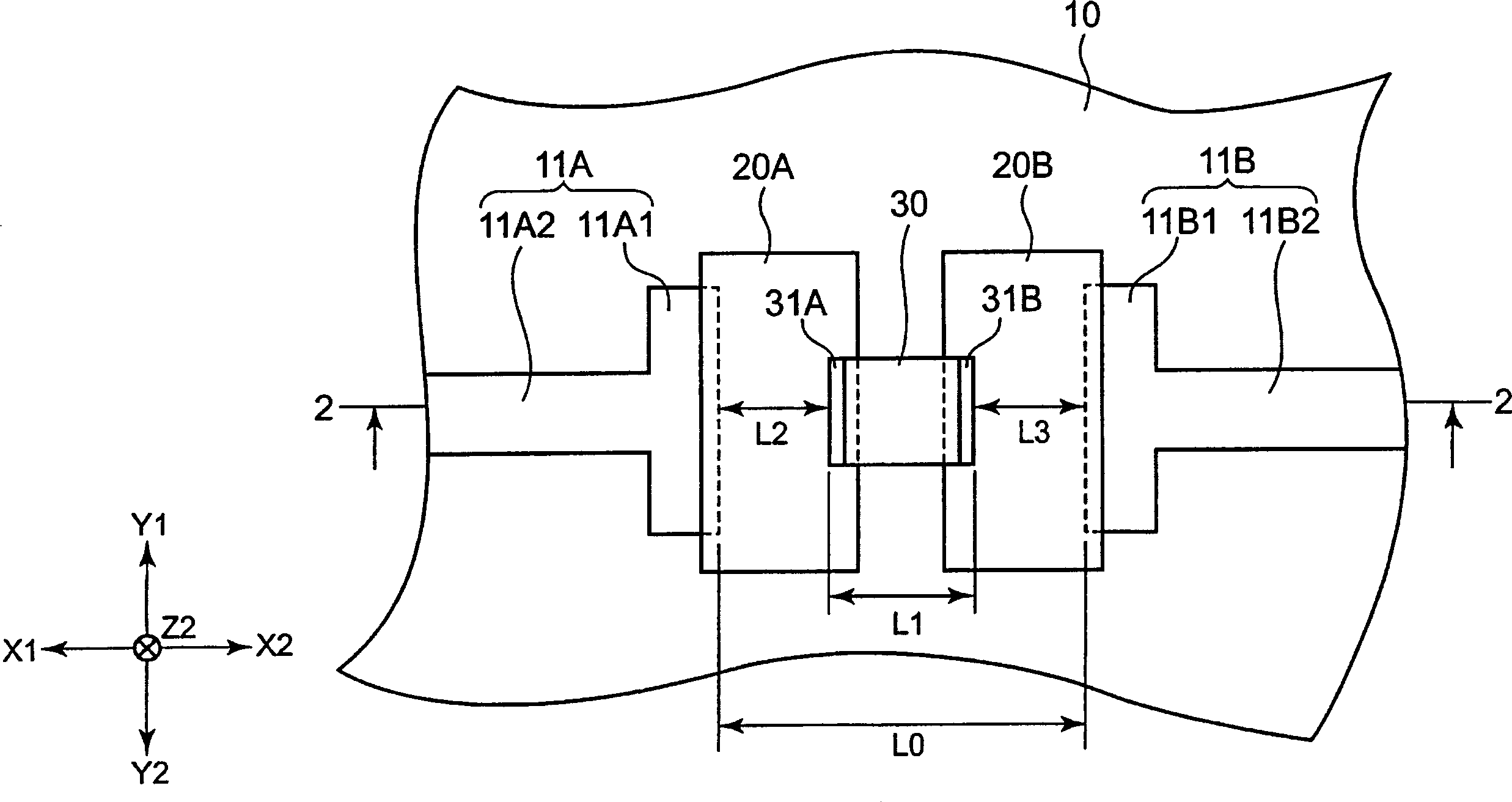

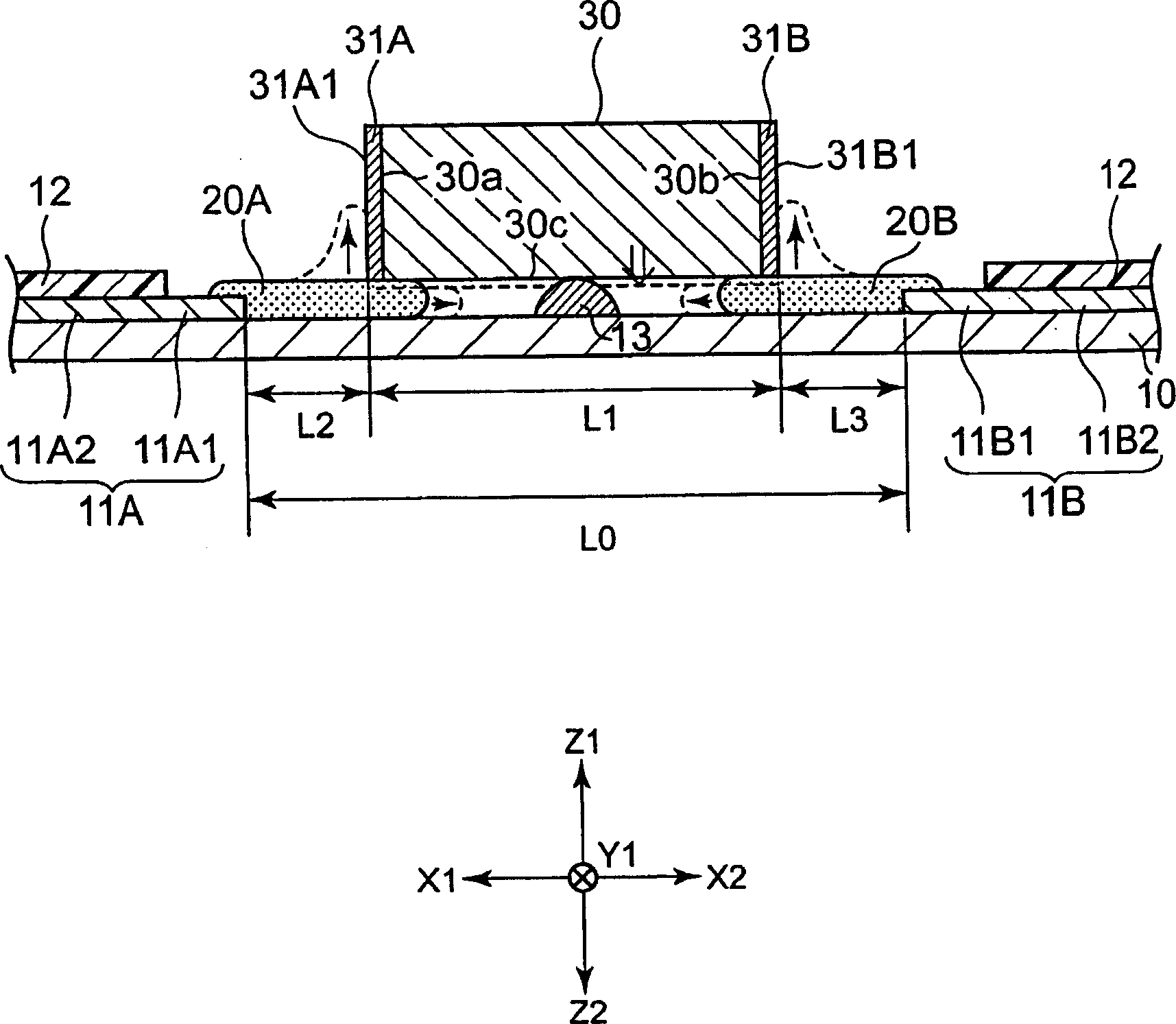

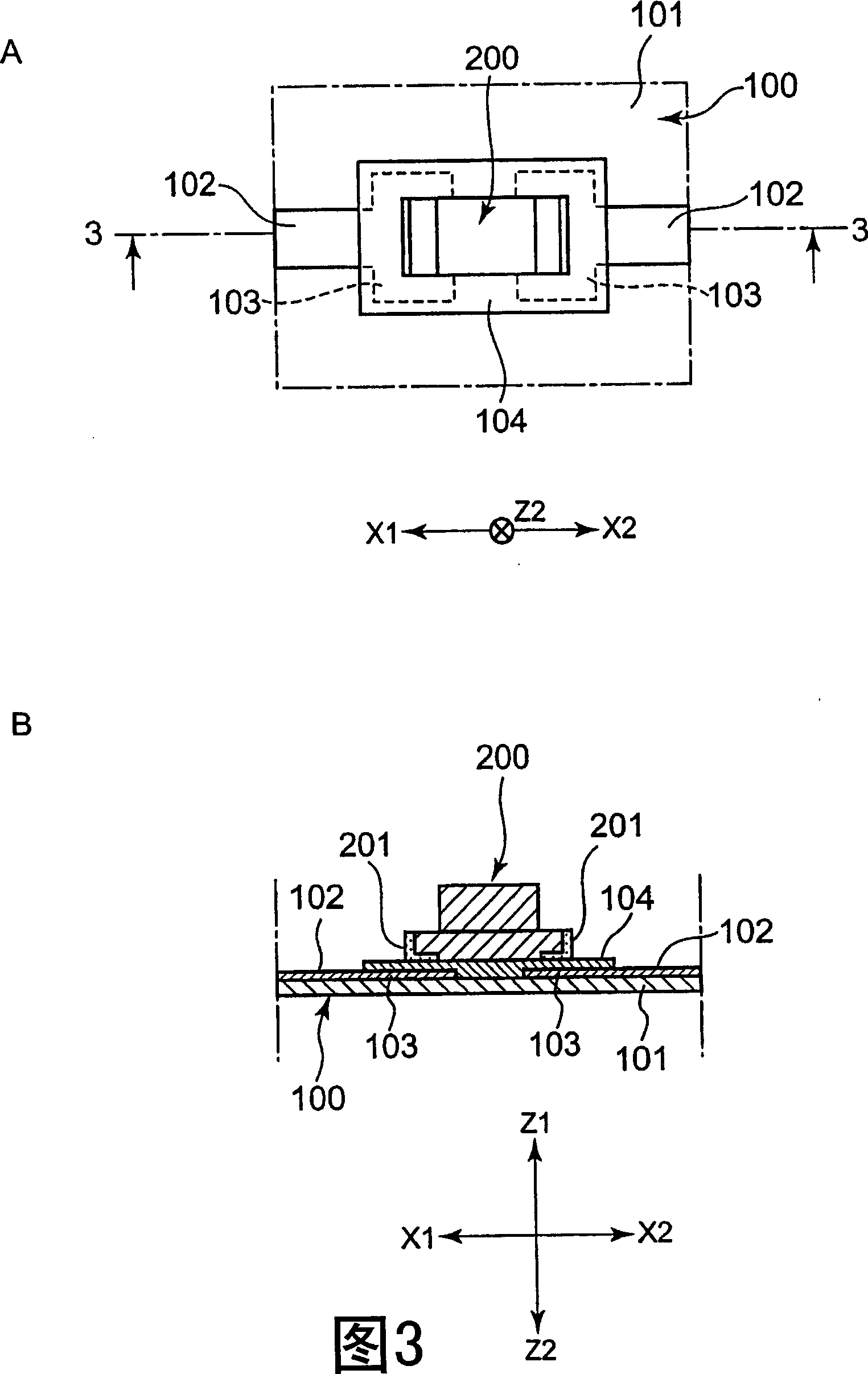

[0021] figure 1 To show a partial plan view of the electronic component mounting substrate of the present invention, figure 2 for along figure 1 A sectional view of the 2-2 line. In addition, in figure 1 In order to clarify the shape of the conductive pattern, etc., the protective layer covering the conductive pattern (resist icon.

[0022] Reference numeral 10 denotes a flexible insulating substrate formed of polyester resin such as polyethylene terephthalate or polyimide resin. Such as figure 1 As shown, a pair of conductive patterns 11A and 11B are formed on the surface of the insulating substrate 10 (the surface on the Z1 side in the drawing) to face each other at a predetermined interval L0 along the X1-X2 direction in the drawing. In addition, in figure 1 Although only one pair of conductive patterns 11A, 11B is shown in FIG. 1 , actually, multiple pairs of conductive patterns are formed on the insulating substrate 10 .

[0023] In the conductive pattern 11A, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com