Manufacturing method for extract of phellinus linteus, the extract and food compositions comprising thereof

A technology of Xyloporus cleft hoof and extract, which can be applied in food preparation, food ingredients, food science and other directions, and can solve the problems of inedible, troublesome time, energy and labor of S.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

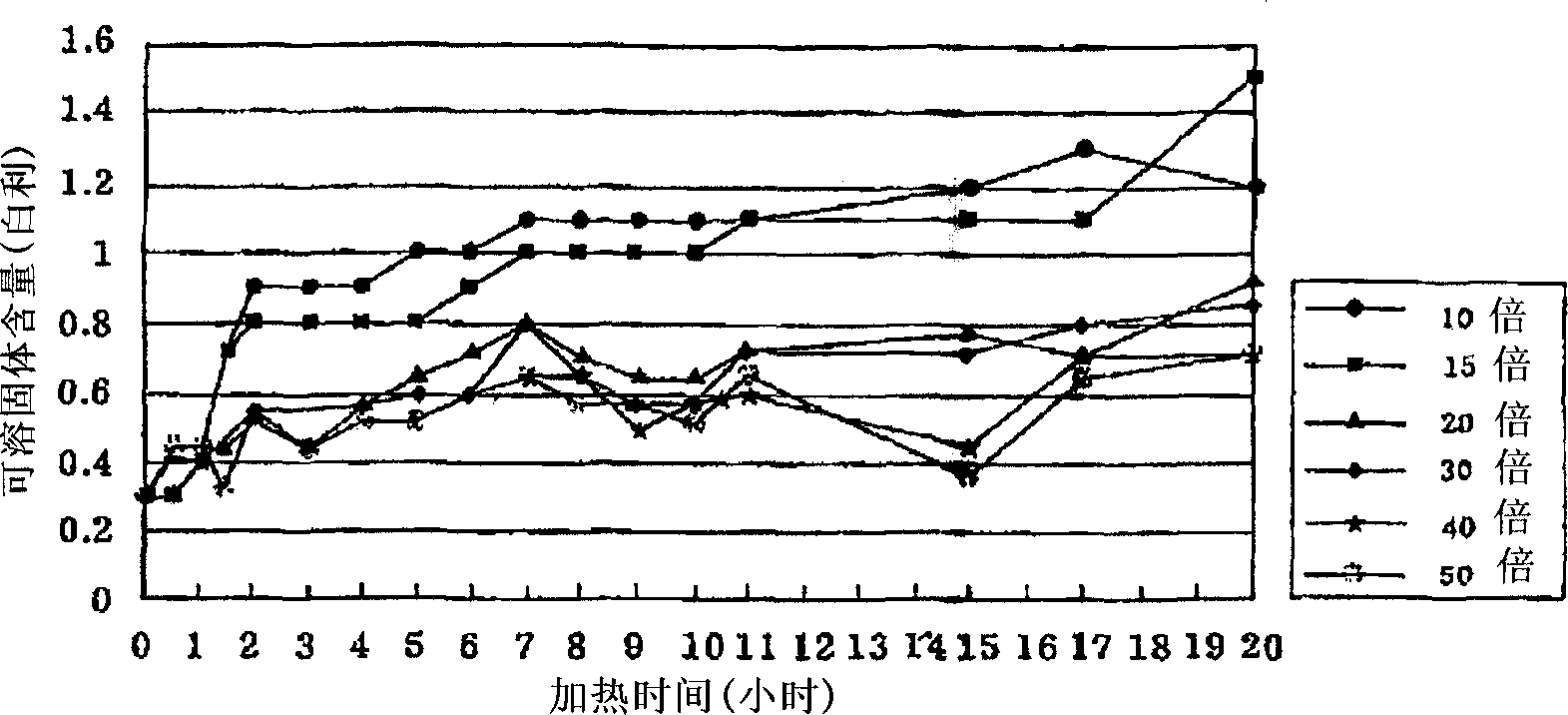

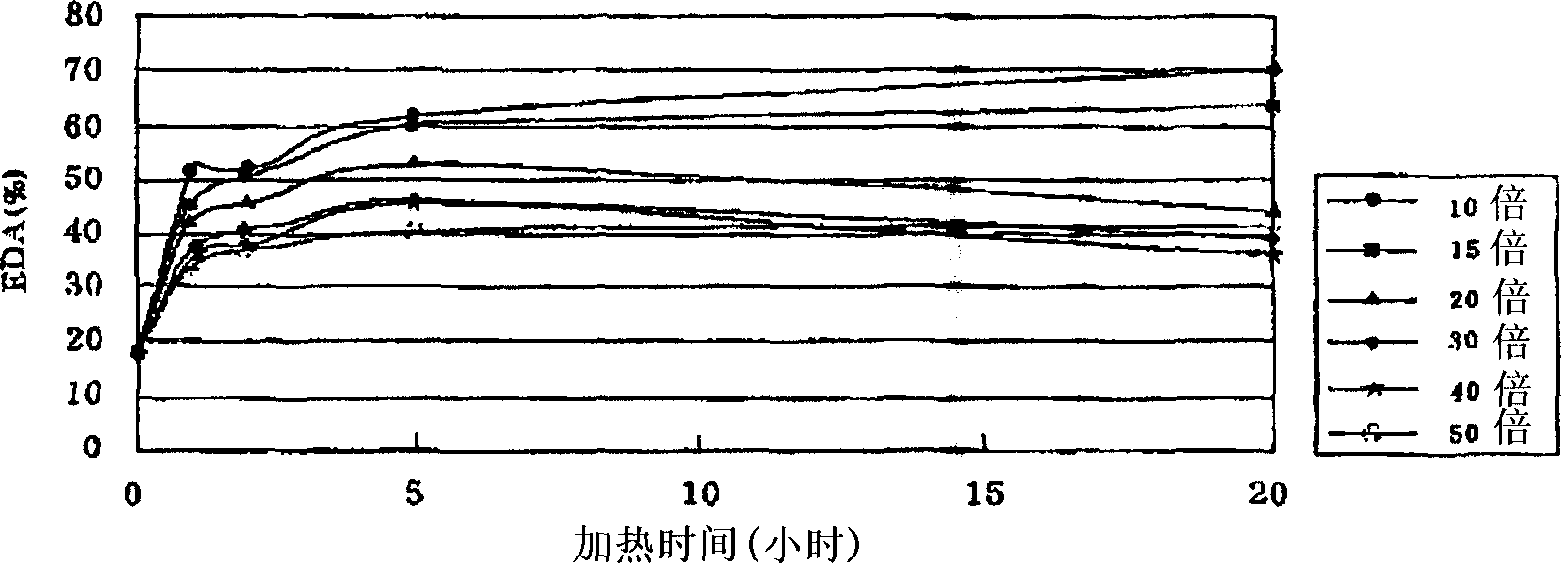

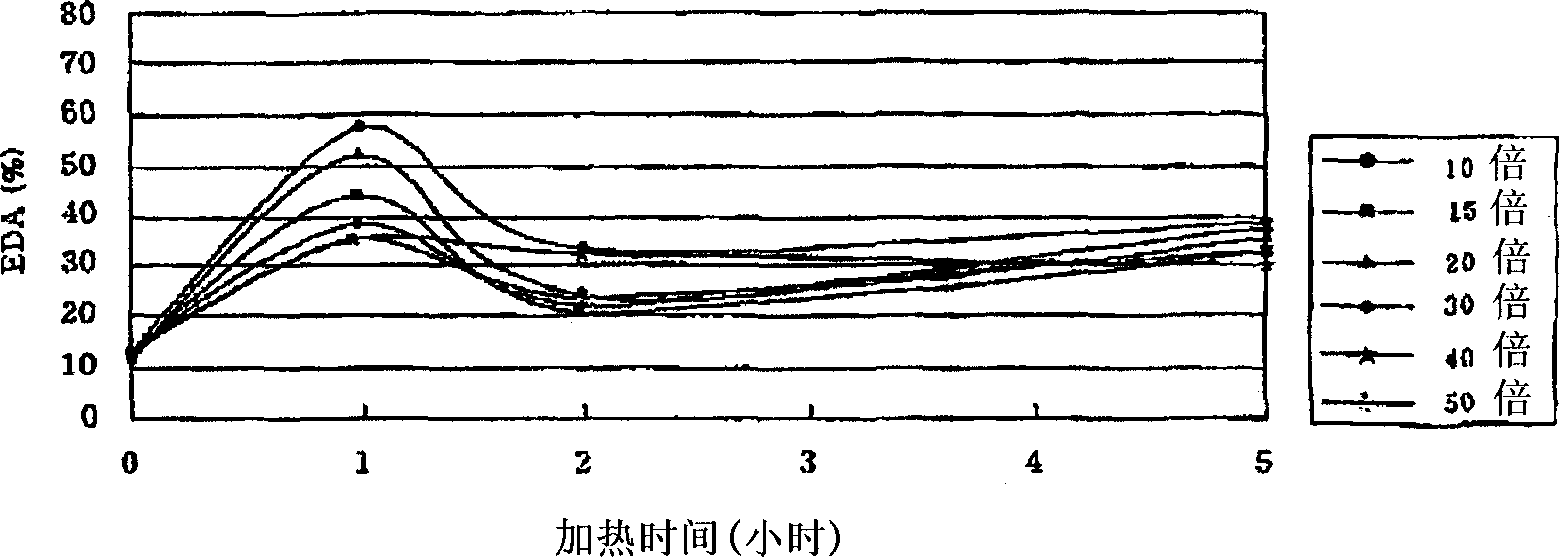

[0030] The preparation of the extract of Phylophora clefthoof

[0031] Preparation of Phlomophorus clefthoof extract (1)

[0032] 5 kg of Phalamopora clefthoof were dried and ground with a mixer to obtain a powder with a size of 20 mesh. 75 L of water was added thereto and thermal extraction was performed at a temperature of 100° C. for 5 hours, followed by filtration. The same procedure was repeated three times to obtain the S. clefthoal extract.

[0033] Preparation of Phlomophorus clefthoof extract (2)

[0034] 5 kg of Phalamopora clefthoof were dried and ground with a mixer to obtain a powder with a size of 20 mesh. Add 75L of water to it and in 15 lbs (1kg / cm 2 ) under pressure at a boiling point of 121° C. for 1 hour and then filtered. The same procedure was repeated three times to obtain the S. clefthoal extract.

[0035] Preparation of Phlomophorus clefthoof extract (3)

[0036] 5 kg of Phalamopora clefthoof were dried and ground with a mixer to obtain a powder ...

Embodiment 2

[0055] Preparation of Vermicelli by Phylophorus clefthoofus Extracted from Hot Water

[0056] Recipe: wheat flour 90 + potato starch 10 as starch raw material, and 1.7% salt (relative to starch raw material, w / w), 0.17% alkaline chemical (Na 2 CO 3 : K 2 CO 3 = 1:1, w / w relative to the starch raw material) and 34% of S. clefthoofus extract (w / v relative to the starch raw material).

[0057] Procedure: Wheat flour, potato starch, salt and alkaline chemicals were mixed for 5 minutes, then the hot water extract obtained in Example 1 was slowly added and mixed together for 15 minutes. The mixture was formed into balls and passed through noodle rolling rolls to form noodle strands with a thickness of 0.8 cm, which were then passed through the rolls 15-20 times to have a final thickness of 2 mm; they were then cut into 2.0 cm mm×1.2mm cross section (rectangular).

Embodiment 3

[0067] Preparation of Ramen Noodles Using Hot Water Extract of Phylophorus clefthoof

[0068] Formula: wheat flour 83+potato starch 11+starch acetate 6 as starch raw material, 1.22% salt (relative to starch raw material, w / w%), 0.16% alkaline chemical (Na 2 CO 3 : K 2 CO 3 = 2:8, relative to the starch material, w / w) and 35% of the extract of Ph.

[0069] Operating steps: Mix wheat flour, starch, salt and alkaline chemicals for 5 minutes, then slowly add the hot water extract obtained in Example 1 and mix together for 15 minutes. The mixture was formed into a ball and passed through a noodle roller to form a noodle bundle with a thickness of 2 cm, which was then passed through a 7-stage roller, and then cut into a 1.8 mm×1.2 mm cross section (circle). Immediately after cutting they were steamed at a temperature of 100°C for 150 seconds, and 130 g of the steamed noodles were immediately fried in palm oil at 143-145°C for 90 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com