Substrate processing apparatus

A substrate processing device and substrate processing technology, which are applied to storage devices, transportation and packaging, conveyor objects, etc., can solve the problem of inability to perform transportation at the same time, and achieve the effect of shortening the time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

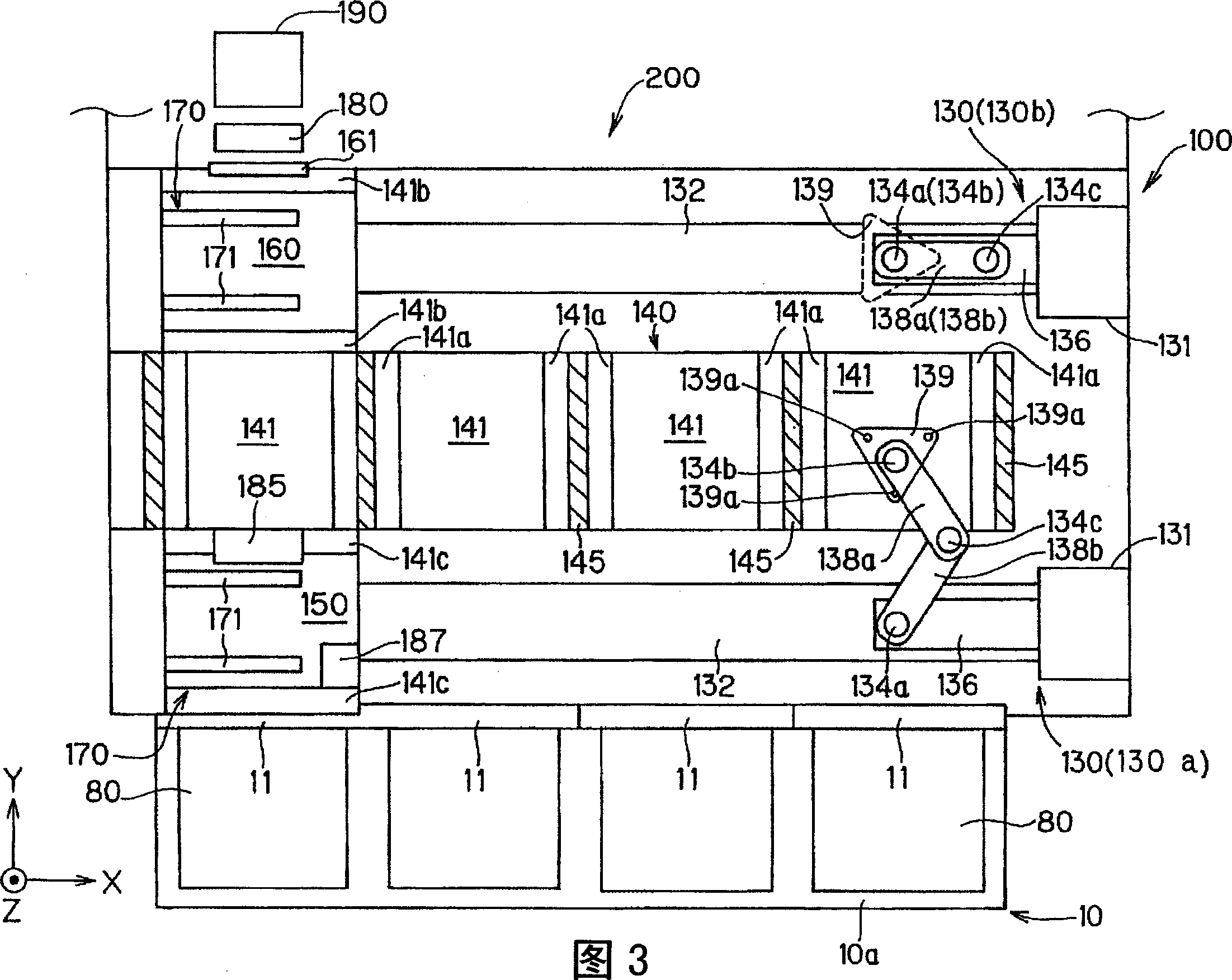

[0043] 1.1. Configuration of substrate processing equipment

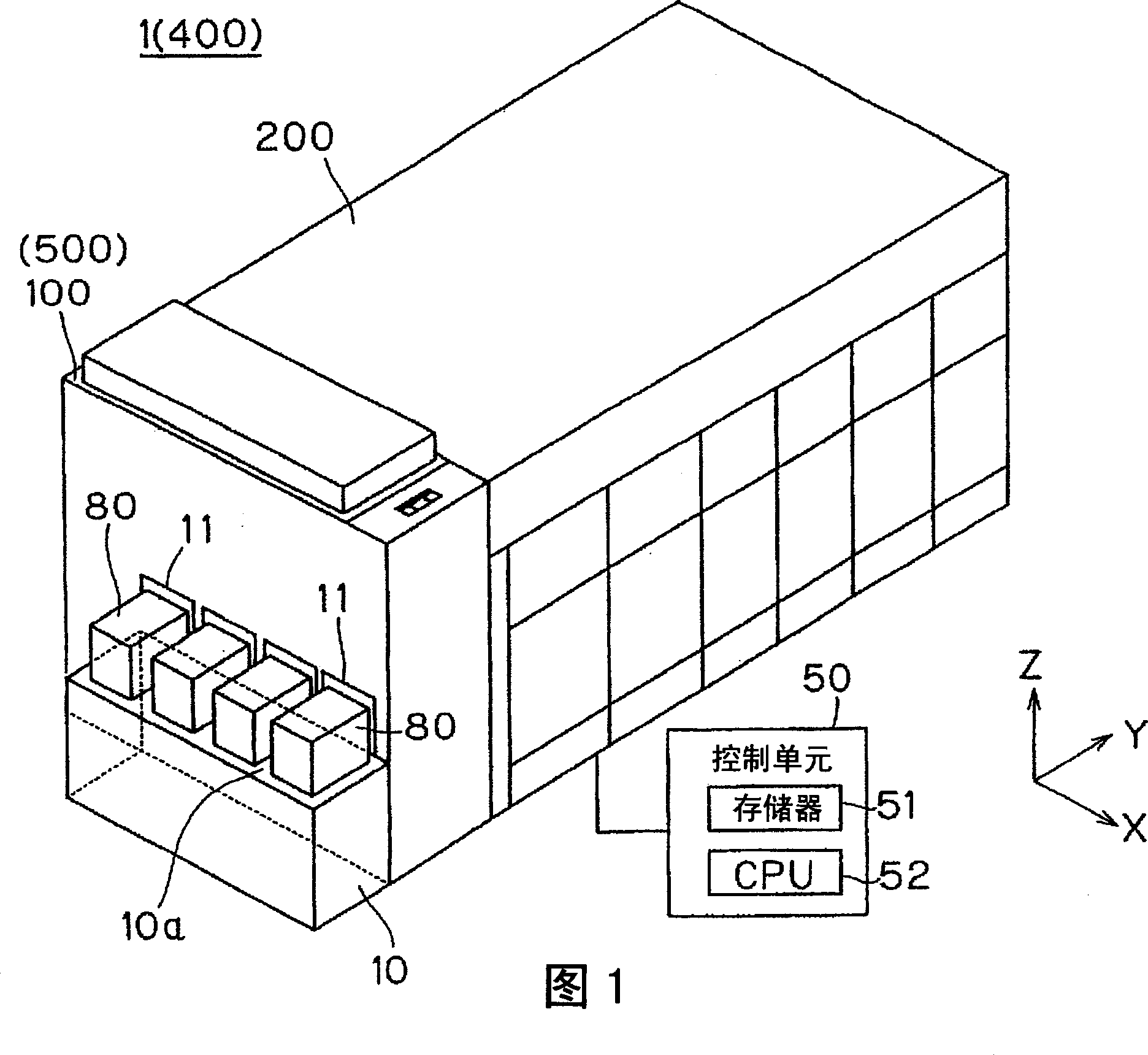

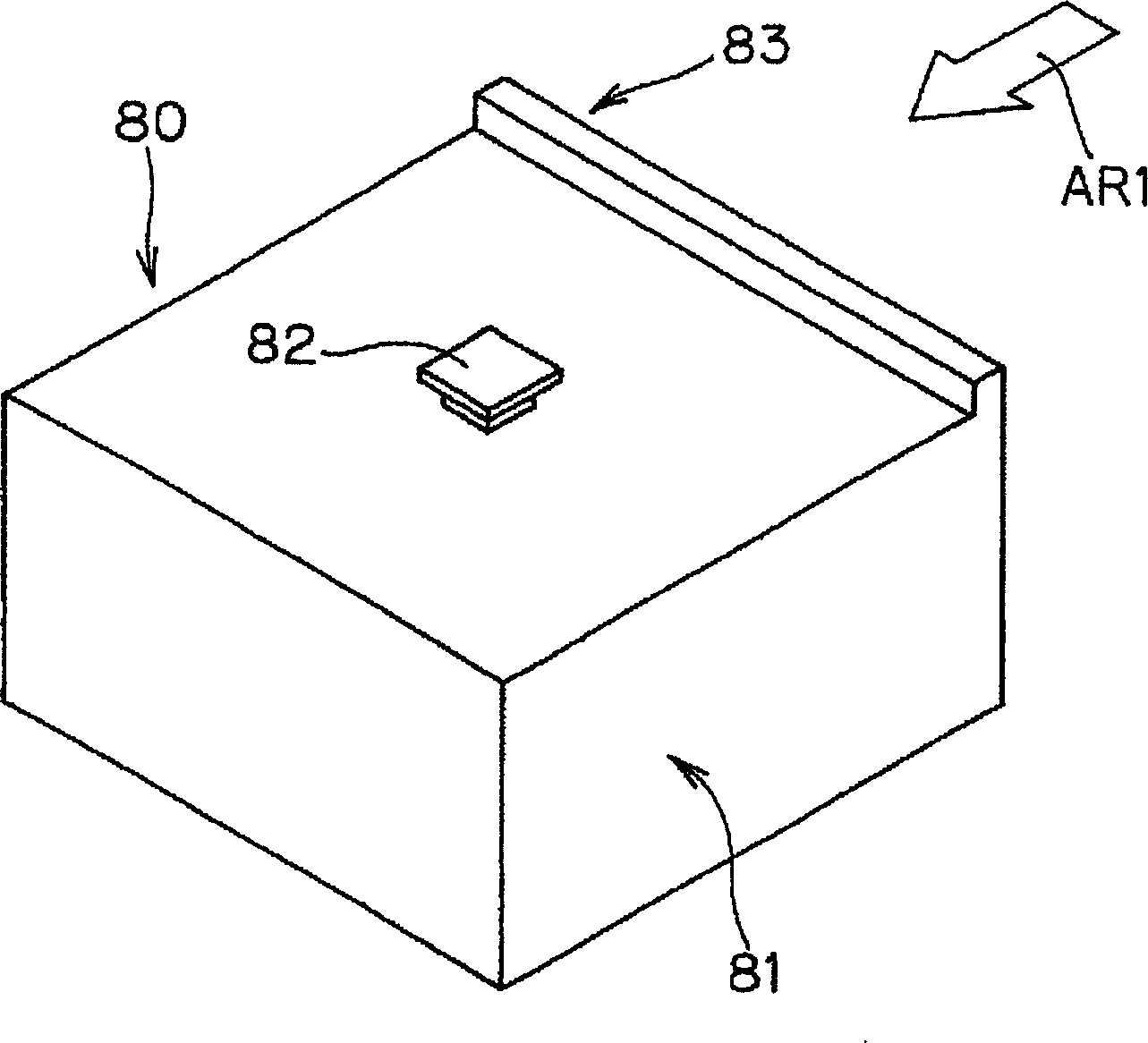

[0044]FIG. 1 is a perspective view showing an overall configuration of a substrate processing apparatus 1 according to an embodiment of the present invention. The substrate processing apparatus 1 is an apparatus that sequentially performs substrate processing in which a group of a plurality of substrates (Lot: lot) stored in a FOUP (frontopening unified pod: front opening unified pod) 80 is taken out from the FOUP, and The plurality of substrates are subjected to etching treatment using a chemical solution such as hydrofluoric acid, rinsing treatment using pure water, and the like. As shown in FIG. 1 , the substrate processing apparatus 1 mainly includes a load port 10 , a loading / unloading unit 100 , and a substrate processing unit 200 . In addition, in FIG. 1 and subsequent drawings, an XYZ rectangular coordinate system is provided in which the Z-axis direction is the vertical direction and the XY plane is the ho...

no. 2 approach

[0111] 2. Second Embodiment

[0112] Next, a second embodiment of the present invention will be described. Compared with the substrate processing apparatus 1 in the first embodiment, the substrate processing apparatus in the second embodiment is the same as the first embodiment except that the loading / unloading unit 500 further includes an orientation unit for orienting the substrate in a predetermined direction. . In addition, in the following description, the same code|symbol is attached|subjected to the same component as the component in the substrate processing apparatus of 1st Embodiment.

[0113] 2.1. Structure of substrate processing equipment

[0114] FIG. 1 is a perspective view showing the overall configuration of a substrate processing apparatus 400 in this embodiment. The substrate processing apparatus 400 is an apparatus that sequentially performs substrate processing in which a group of a plurality of substrates (Lot: lot) stored in a FOUP (frontopening unifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com