Stirling engine

A Stirling engine and reciprocating motion technology, applied to refrigerators, compressors, lighting and heating equipment, etc., can solve the problems of indispensable performance testing and difficult readjustment, and achieve improved assembly, reliability, and Ease of improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

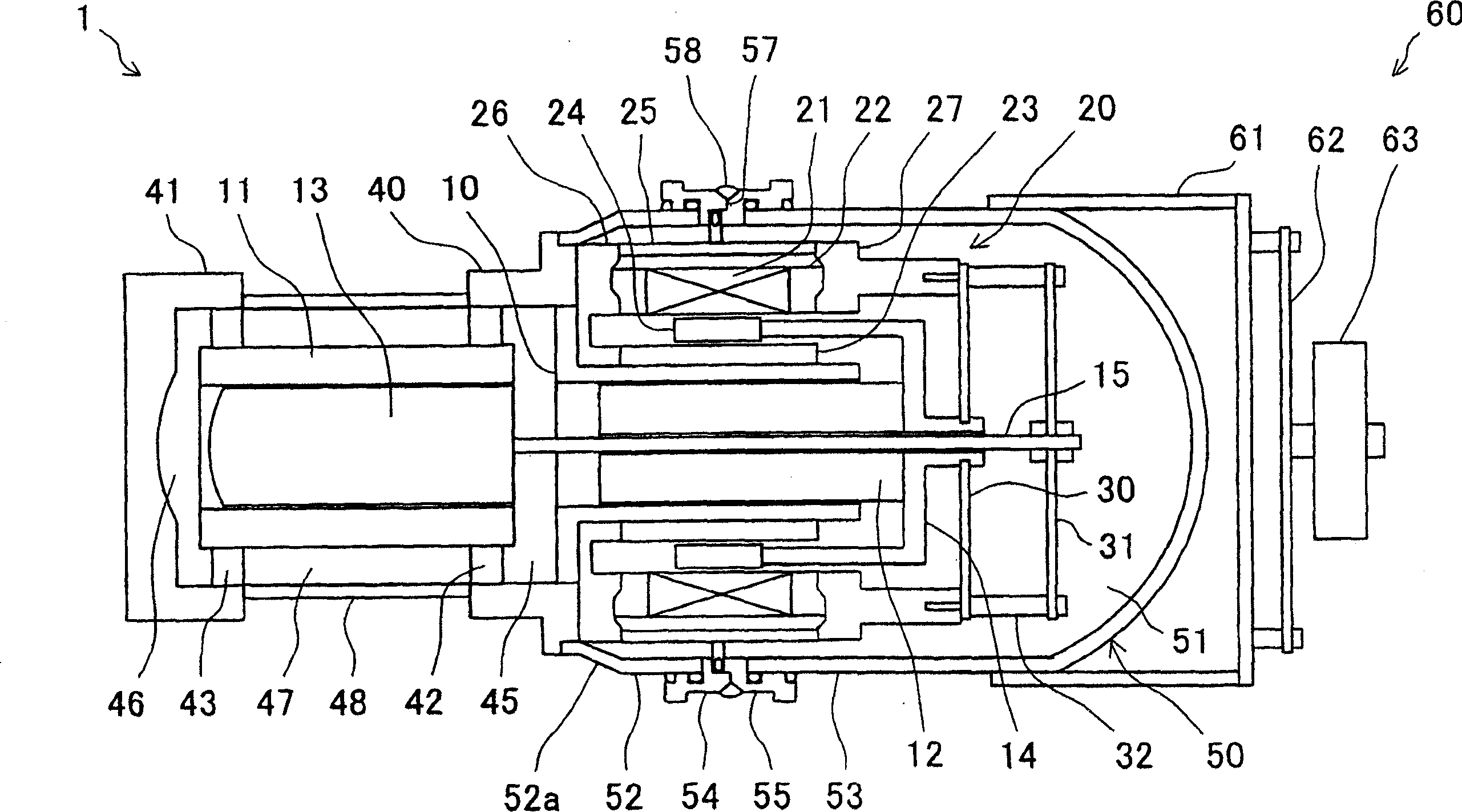

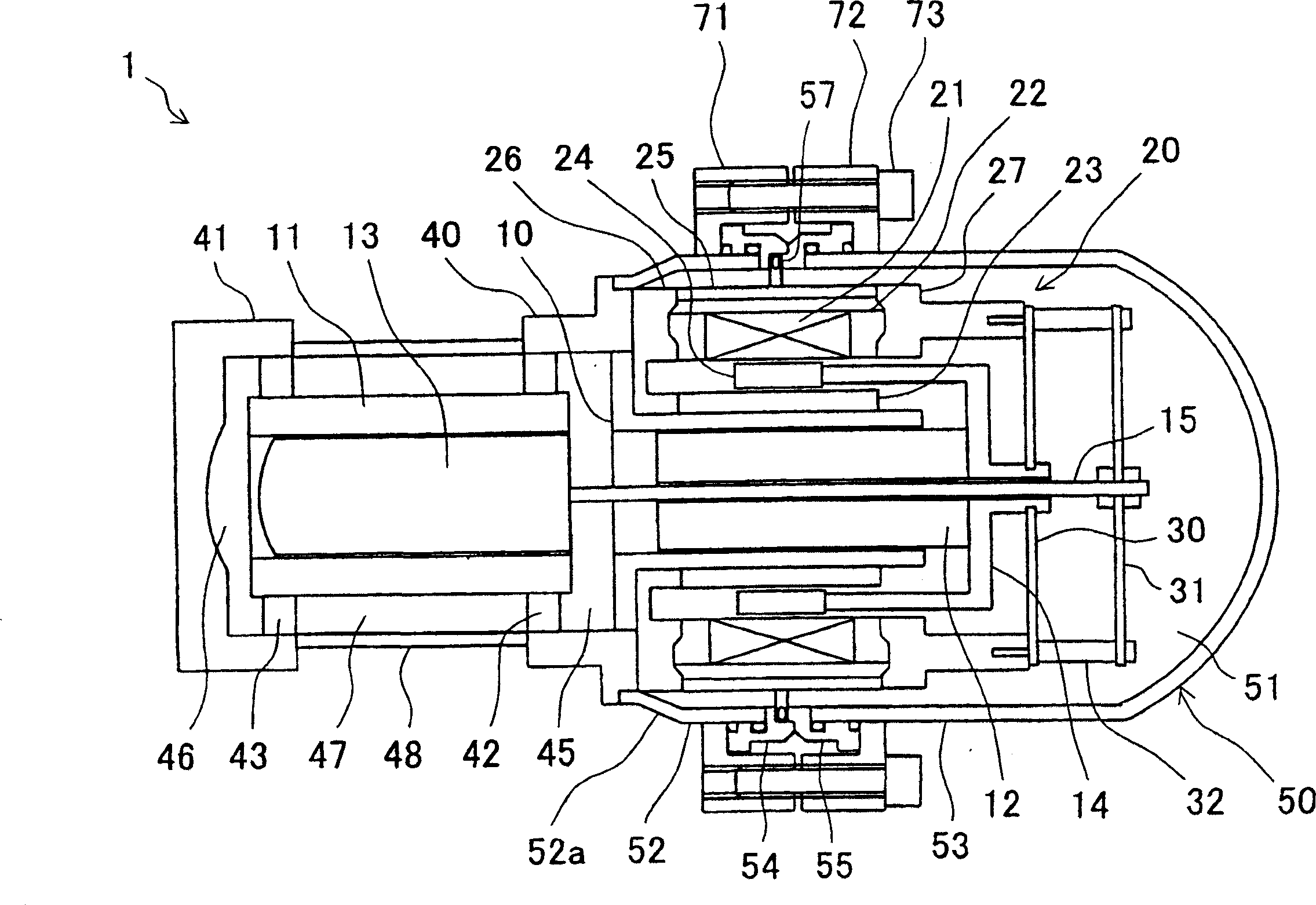

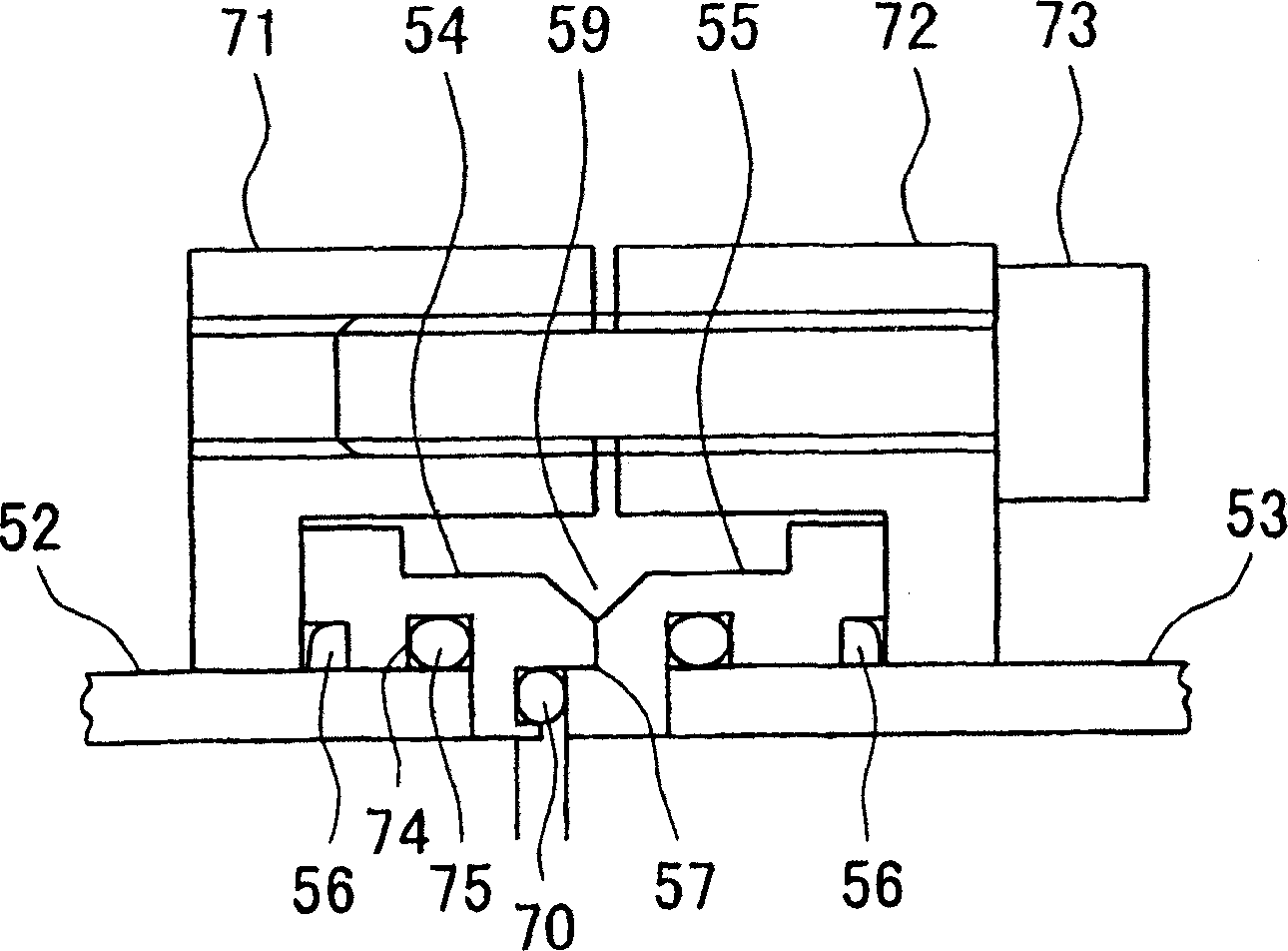

[0044] Embodiments of the present invention will be described below with reference to the drawings. Figure 1-Figure 3 represents the first embodiment. figure 1 It is a sectional view of the finished product of the Stirling engine, figure 2 is a cross-sectional view of the temporary bonding stage, image 3 Yes figure 2 The enlarged view of the main part.

[0045] Central to the assembly of the Stirling engine 1 are the pressure cylinders 10 , 11 . The axes of the pressure cylinders 10, 11 are aligned on the same straight line. A piston 12 is inserted into the pressure cylinder 10 , and a displacer 13 is inserted into the pressure cylinder 11 . During the operation of the Stirling engine 1 , the piston 12 and the displacer 13 reciprocate without contacting the pressure cylinders 10 and 11 by the structure of the gas bearing.

[0046] One end of the piston 12 is fixed with a cup-shaped magnet holder 14 . A displacer shaft 15 protrudes from one end of the displacer 13 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com