Fine seam type coating device

A coating device and slit technology, which is applied in the direction of devices and coatings for coating liquid on the surface, to achieve the effect of increasing the adjustable range, improving the swelling phenomenon and increasing the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

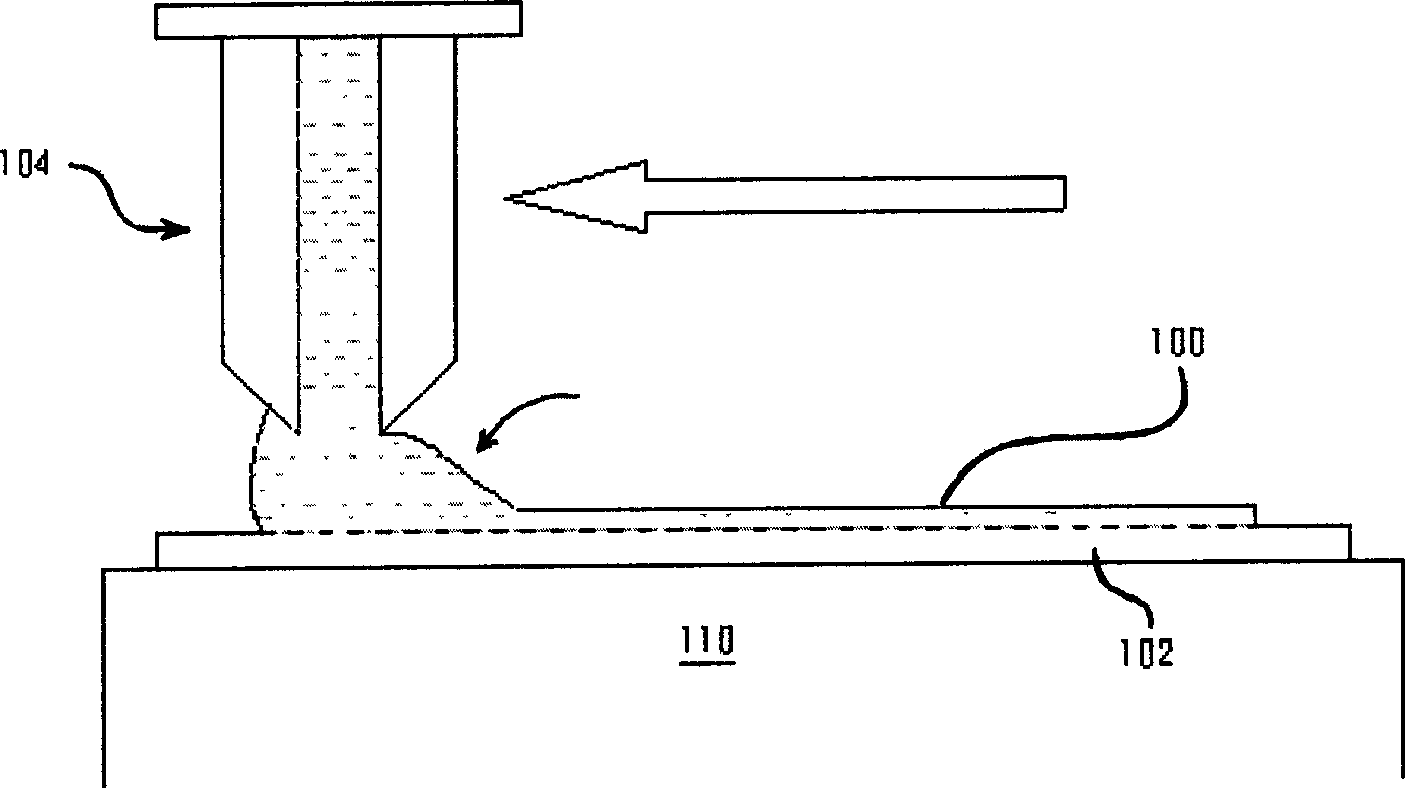

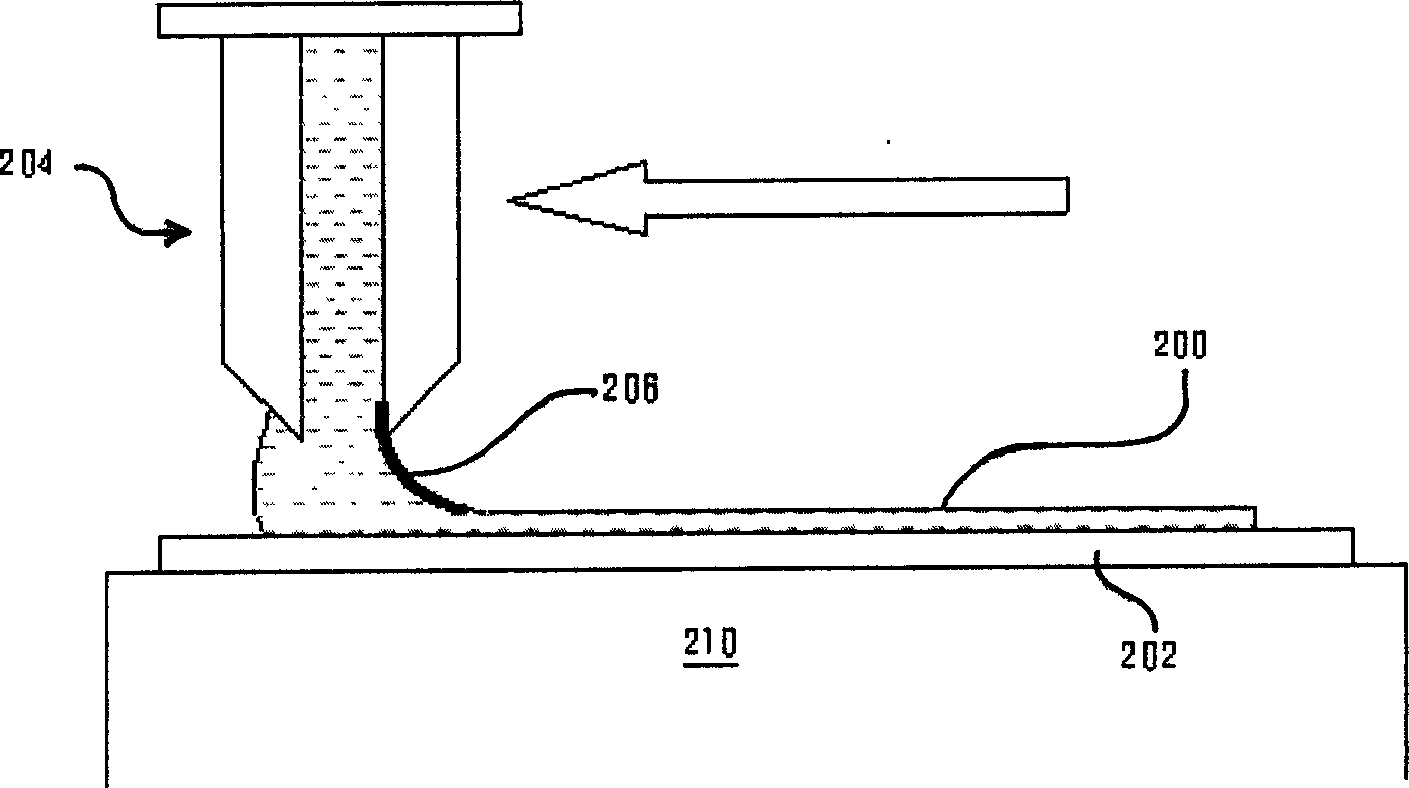

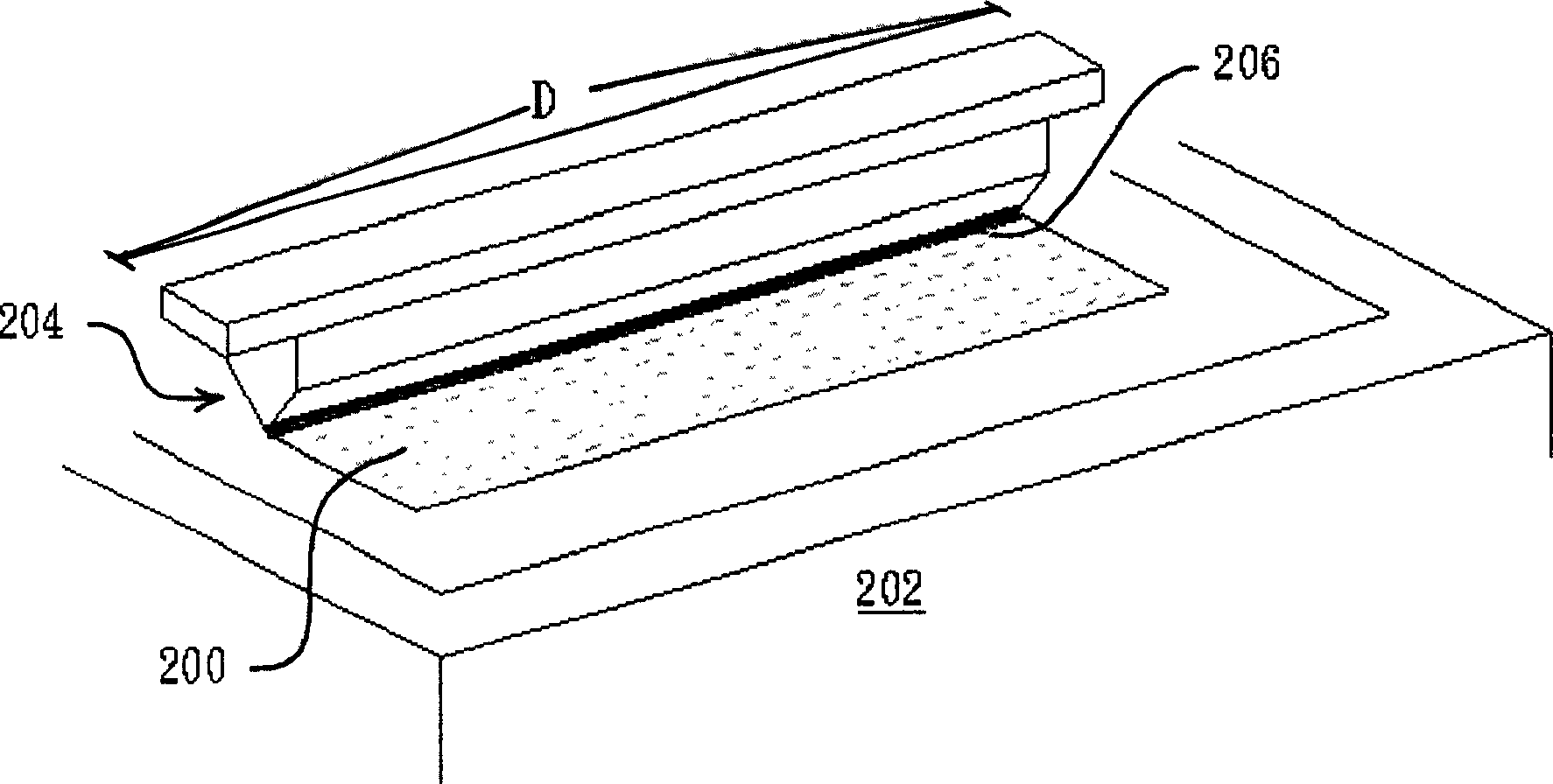

[0021] In order to solve the swelling phenomenon when the coating material is extruded out of the nozzle in the slit coating method, the invention provides a slit coating device. In the coating device, a membrane is arranged on the slit coating nozzle so that the membrane extends outward from the slit coating nozzle, and the width of the membrane covers the discharge range of the slit coating nozzle. When the coating material is extruded out of the nozzle, it will be coated on the substrate along the membrane, thus improving the expansion phenomenon of the coating material and increasing the stability of the coating film.

[0022] Such as Figure 2A Shown is a side view of a slot coating device according to a preferred embodiment of the present invention. In this preferred embodiment, a membrane 206 is disposed on the nozzle 204 of a slit coating device. The diaphragm extends outward from the slit opening 204a. When performing slit coating, the nozzle 204 and the base 210 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com