Device for ultrasonic welding

A technology of ultrasonic welding and ultrasonic welding electrode, which can be used in welding equipment, non-electric welding equipment, metal processing equipment, etc., and can solve problems such as insufficient welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

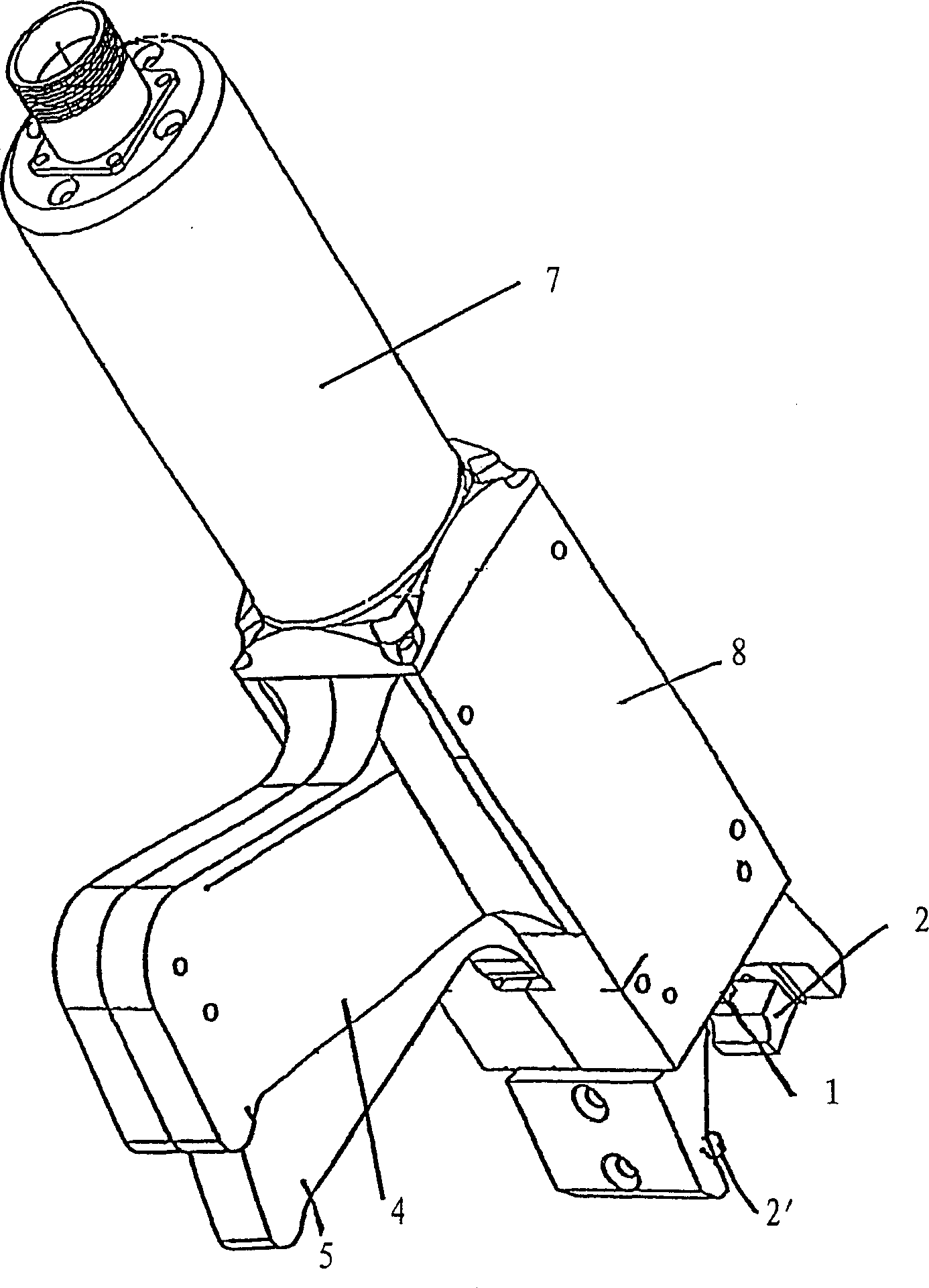

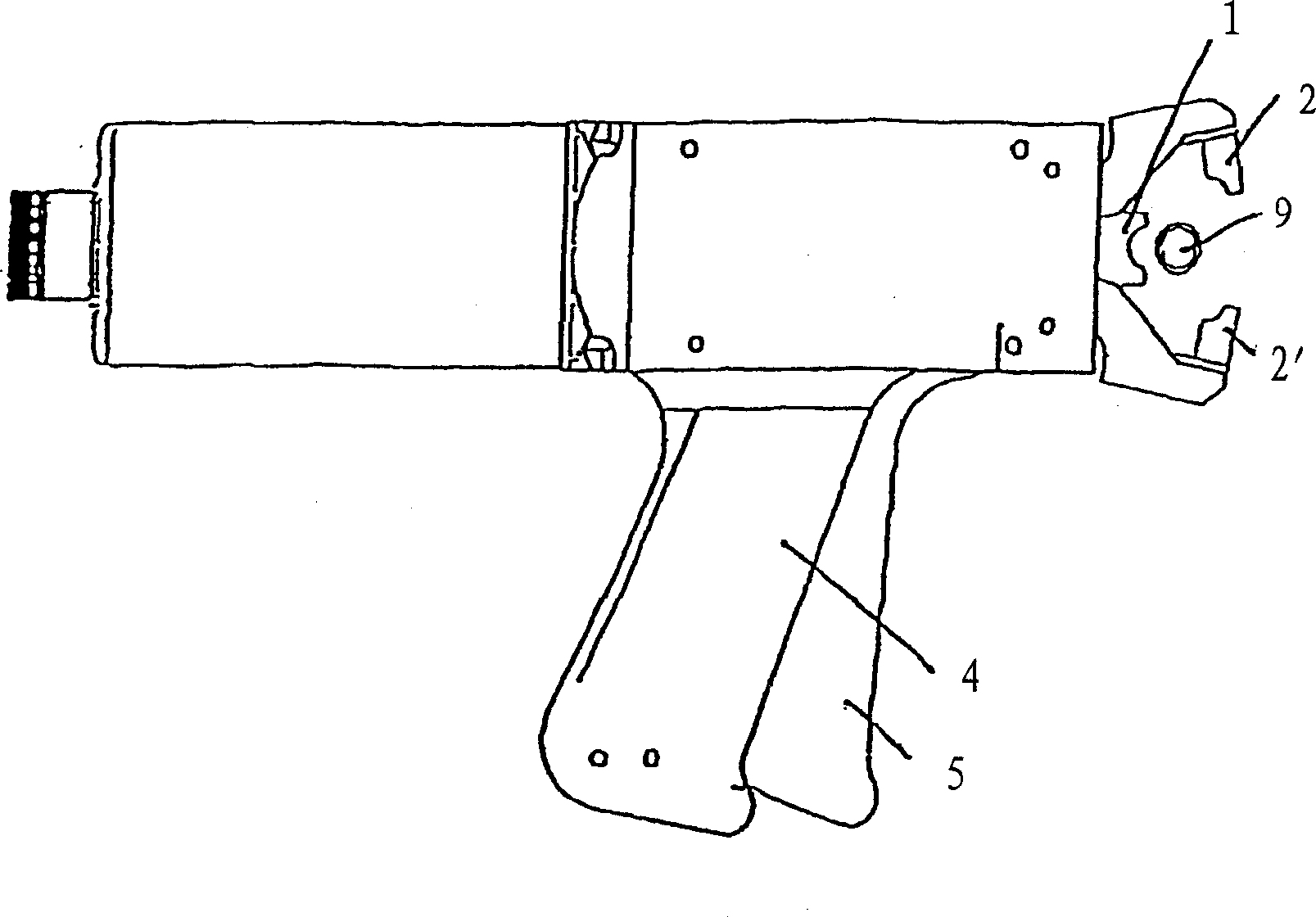

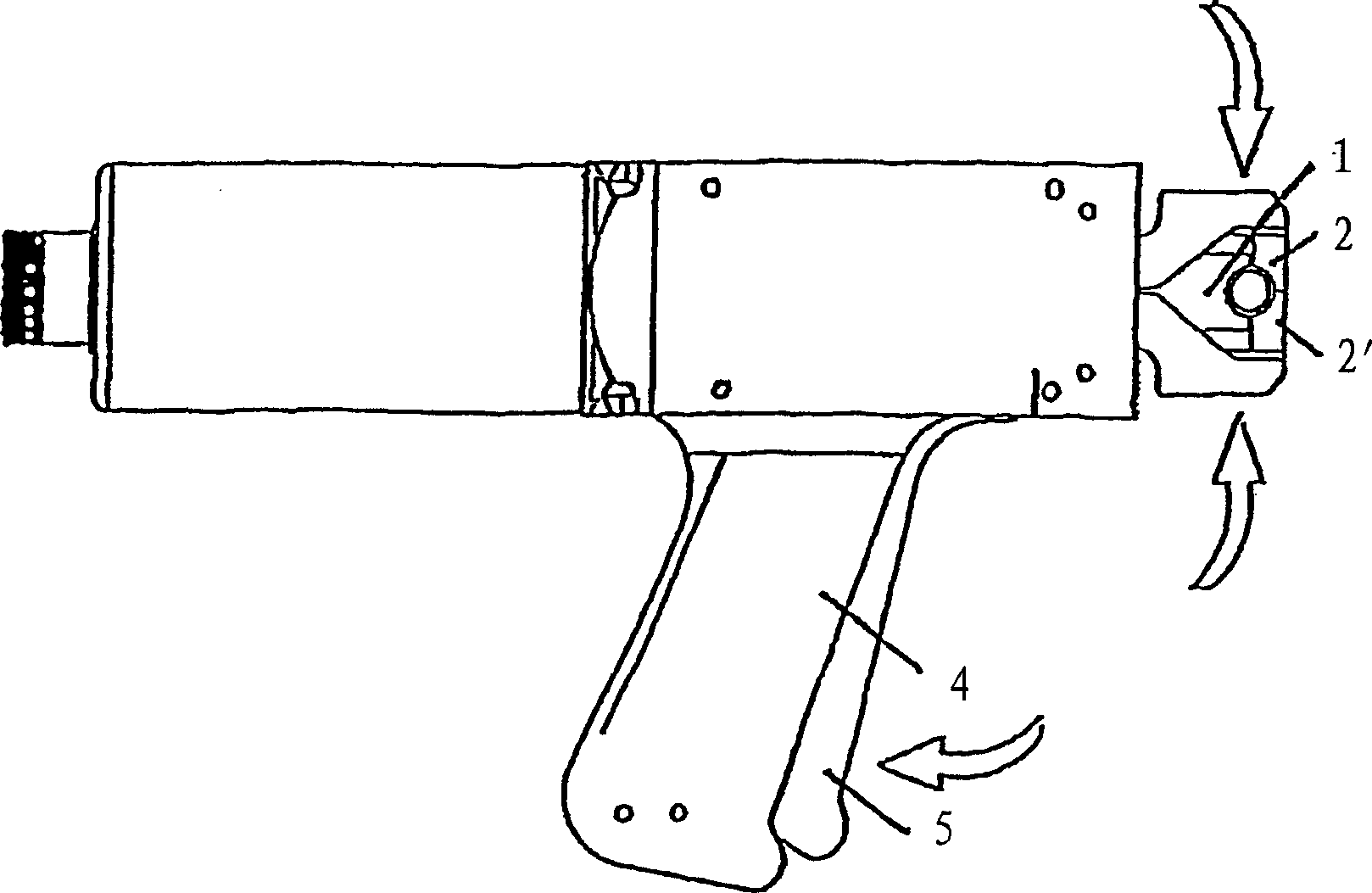

[0023] figure 1 Shown is an exemplary embodiment of a device according to the invention shown in a schematic perspective view. It mainly includes a sonotrode 1 that generates ultrasonic vibrations and two anvils 2, 2'. The two anvils and the sonotrode form a radial cross-section of the welded material in the welding state. Compression chamber bounded by sonotrode 1 and anvil 2, 2' to compress and / or slightly deform the material to be welded, such as a plastic corrugated hose, where the two anvils 2, 2' are positioned mutually Mobile and rotatable, the shape of the inside of the anvil 2, 2' is designed to be recessed.

[0024] The sonotrode 1 is excited via an oscillator (not shown in the figure), which transmits its energy to the sonotrode 1 largely inside the housing 8 via a pressurizer 7 .

[0025] In addition, the device according to the invention has a pistol-grip-shaped handle 4 on which a grip-shaped actuating element 5 is arranged.

[0026] After inserting a corrugat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com