Corrosion resistant fuel cell terminal plates

A terminal plate, corrosion-resistant layer technology, used in fuel cells, fuel cell components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following description of the preferred embodiments is merely exemplary in nature and is not intended to limit the invention and its adaptation and uses.

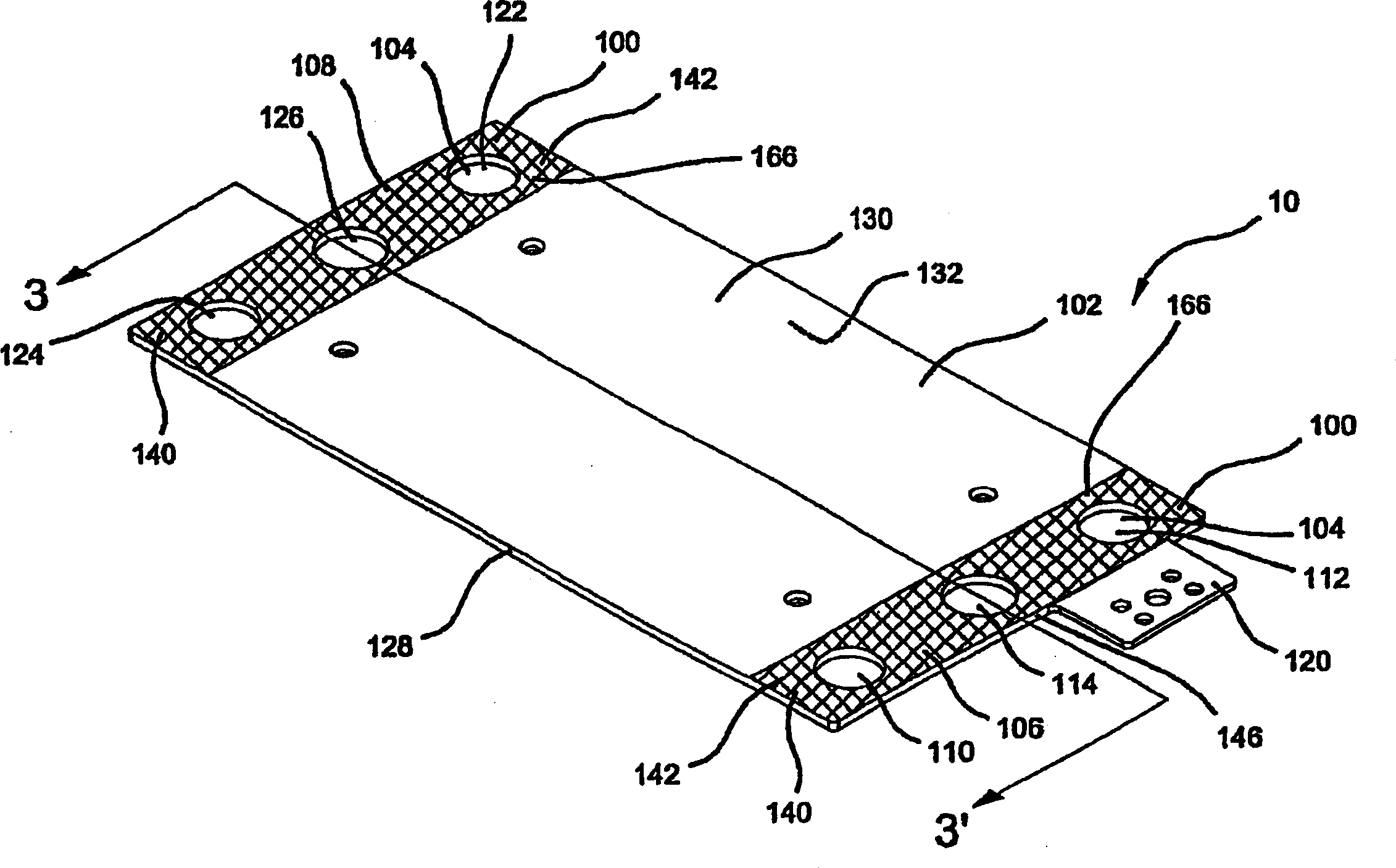

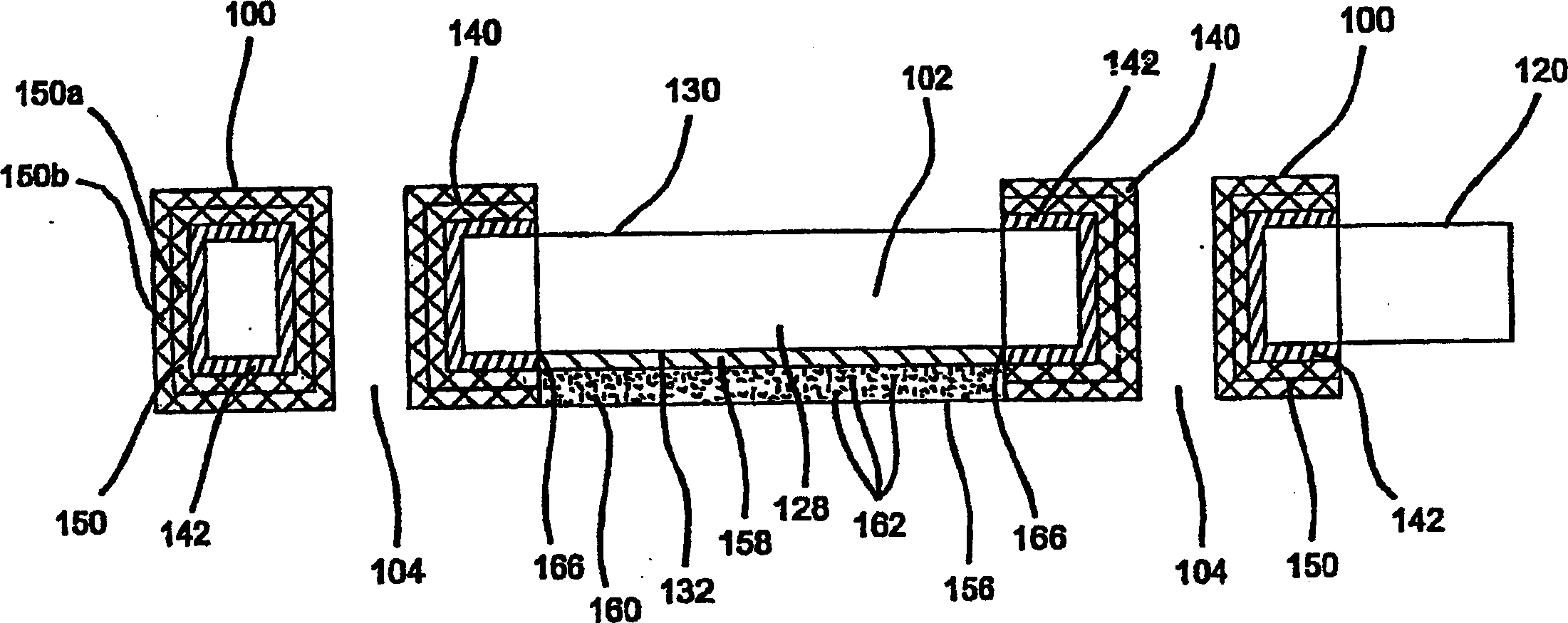

[0015] The present invention contemplates a terminal current collector end plate (hereinafter "termination plate") in an electrochemical fuel cell stack that employs a lightweight, corrodible conductive material having conductive and non-conductive regions, where no Conductive areas are treated to resist corrosion and minimize surface conductivity. Further, another aspect of the invention contemplates the conductive region of the termination plate being coated with a conductive, oxidation resistant protective coating. First, for a better understanding of the present invention, a description of a typical fuel cell and stack is provided herein.

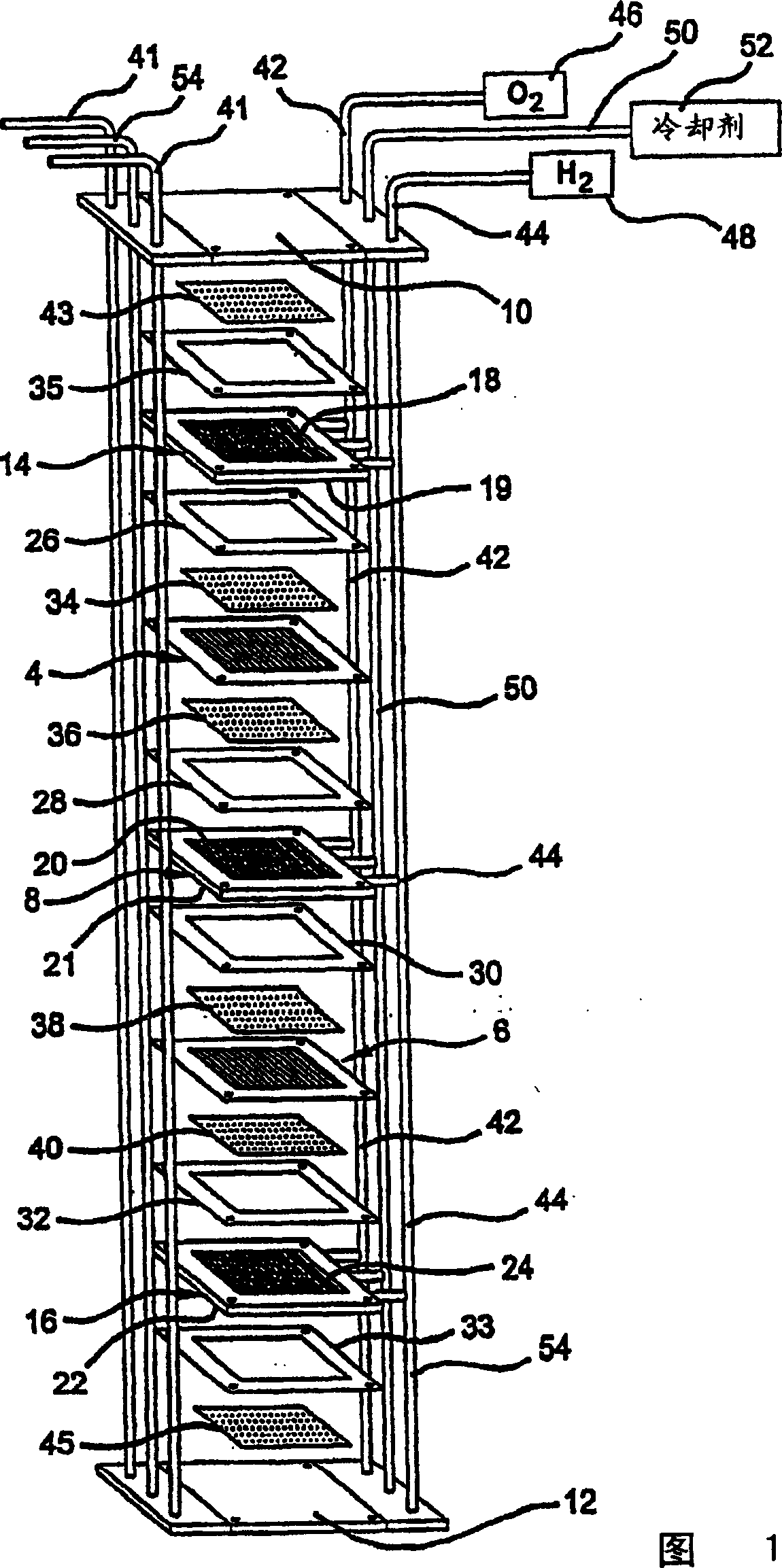

[0016] Figure 1 depicts two individual proton exchange membrane (PEM) fuel cells connected to form a stack with a pair of membrane electrode assemblies (MEAs) 4 and 6 sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com