Polymer thermomechanical property testing device

A testing device and polymer technology, applied in the field of polymers, can solve problems such as limiting the application of polymer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

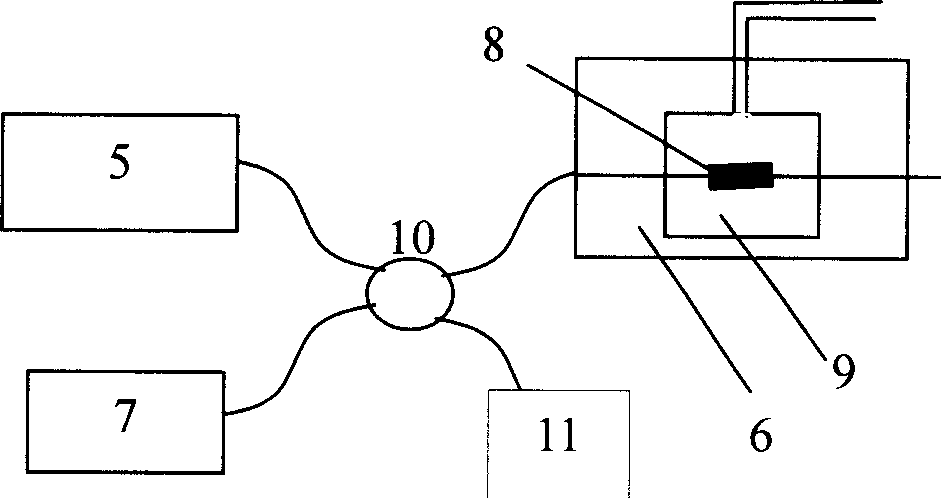

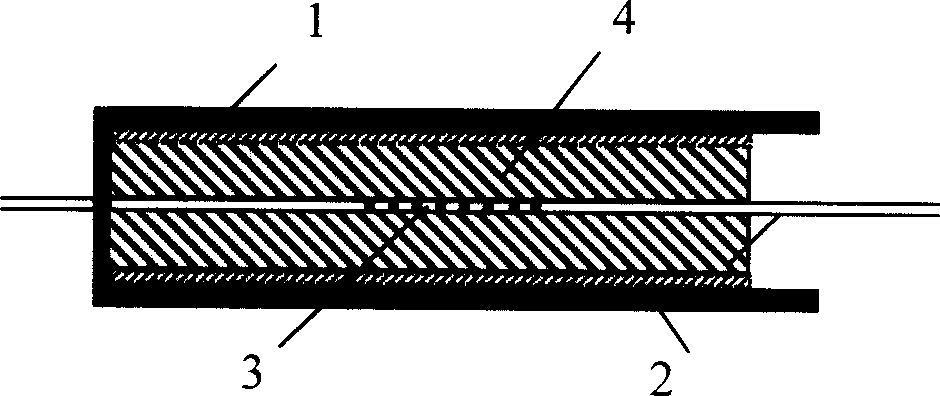

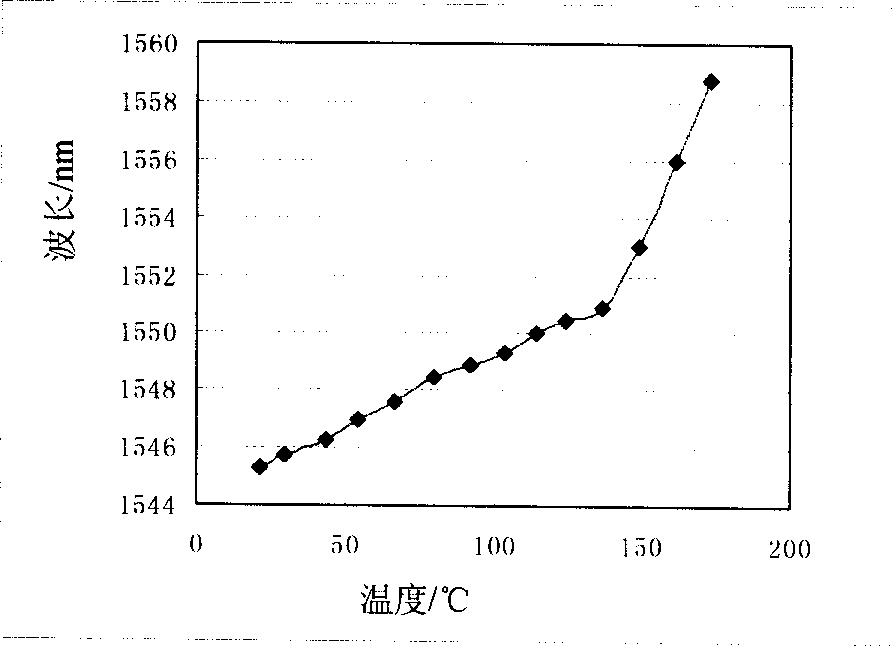

[0017] First, a polymer 4 to be tested is selected to pot the fiber grating sensor 3. During the potting process, the metal casing 1 is first inclined, and then the liquid of the polymer 4 is slowly injected along the metal casing 1, and the fiber grating sensor 3 is packaged in the metal casing 1, and finally the polymer 4 is heated and solidified to form a measuring piece 8, such as figure 2 shown. The measuring piece 8 is placed in the hydraulic device 9, and then the hydraulic device 9 is placed in a temperature control box 6, so as to apply temperature and pressure to it at the same time. The light emitted by the broadband light source (BBS) 5 enters the fiber grating sensor 3 through the 3dB coupler 10, and after being reflected, it is sent to the wavelength demodulation device 7 through the 3dB coupler 10, and the fiber grating sensor 3 is observed through the wavelength demodulation device 7 The change of reflection peak center wavelength Δλc and bandwidth Δλ 3dB . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com